Magnetic immobilized cellobiase nano mesoporous material and preparation method thereof

A technology of nano-mesoporous materials and cellobiase, which is applied in the directions of immobilized on or in inorganic carriers, fixed on/in organic carriers, etc., can solve the problems of recovery of immobilized enzymes, and the number of repeated uses is small , limit applications and other issues, to achieve the effect of improving storage stability and use temperature, reducing production costs and prolonging the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

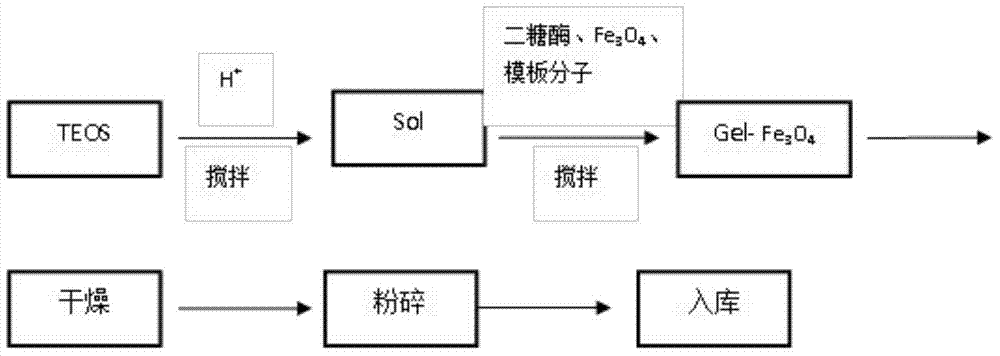

[0032] According to preparation method of the present invention and above-mentioned principle picture , the method further enters the step of removing the template and drying step S1300: grind the gel, wash with water to remove the template and obtain the gel by suction filtration, embed the gel obtained by suction filtration into silica gel for drying for 3-7 days, and dry the dried The gel is ground through a 40-mesh sieve and packed into bags for later use.

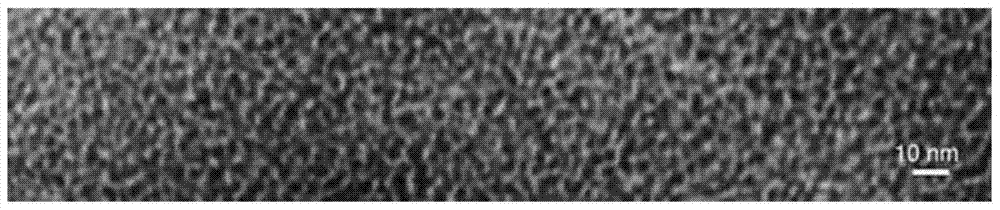

[0033] The activity of the mesoporous material immobilized cellobiase product prepared according to the present invention can reach more than 80% of the activity of free cellobiase, and can be reused more than ten times without reducing the activity; The magnetic nanoparticles can be recycled and used, thereby greatly reducing the production cost of cellulosic ethanol; the use of mesoporous materials to immobilize cellobiase can improve the storage stability and use temperature of cellobiase, and prolong its storage p...

Embodiment 1

[0038] according to picture The preparation method of the magnetically immobilized cellobiase nano-mesoporous material of the present invention shown in 1 first enters the sol formation step S1100: take 32 grams of tetraethyl orthosilicate (TEOS), add 5 grams of 0.1M The dilute HCl solution, the mass ratio of hydrochloric acid solution to TEOS is 5:32, after vigorous stirring for 10 minutes, TEOS is hydrolyzed at room temperature with dilute acid as a catalyst to form a transparent sol, and the hydrolyzed transparent sol is cooled at 0°C for 2 hours Finally, use a high-vacuum system to extract the by-product ethanol produced in the hydrolysis process of the system. After the extraction for a period of time, keep the temperature of the sol water bath at 37°C for extraction until the mass content of ethanol in the sol is ≤5%.

[0039] Then enter the gel formation step S1200: add template solution, cellobiase buffer and magnetic nano-Fe in sequence to the sol under stirring 3 o...

Embodiment 2

[0042] according to picture The preparation method of the magnetically immobilized cellobiase nano-mesoporous material of the present invention shown in 1 first enters the sol formation step S1100: take 32 grams of tetraethyl orthosilicate (TEOS), add 13 grams of 0.3 M The mass ratio of hydrochloric acid solution to TEOS is 13:32. After stirring vigorously for 20 minutes, TEOS is hydrolyzed at room temperature with dilute acid as a catalyst to form a transparent sol, and the hydrolyzed transparent sol is cooled at 10°C for 4 hours. Finally, use a high-vacuum system to extract the by-product ethanol produced in the hydrolysis process of the system, and after a period of extraction, keep the temperature of the sol water bath at 50°C for extraction until the mass content of ethanol in the sol is ≤5%.

[0043] Then enter the gel formation step S1200: add template solution, cellobiase buffer and magnetic nano-Fe in sequence to the sol under stirring 3 o 4 Particles, adjust the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com