Method for preparing 2-phenylethyl alcohol

A technology of phenylethyl alcohol and phenylalanine, applied in the chemical industry, can solve the problems of low aroma quality of 2-phenylethyl alcohol and high impurity content of 2-phenylethyl alcohol, so as to shorten the biotransformation cycle, improve the conversion efficiency, and achieve remarkable technological progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

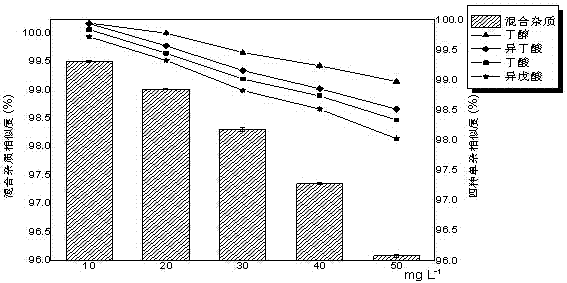

Image

Examples

Embodiment 1

[0018] The biotransformation medium used in this example consists of 10 g / L L-phenylalanine, 30 g / L glucose, and 5 g / L K 2 HPO 4 , 5 g / L MgSO 4 ·7H 2 It is composed of O, 1 g / L NaCl and the balance of water, pH 6.5.

[0019] After sterilizing the above-mentioned NBS BIOFLO 3000 mechanically stirred fermenter with 3.5L fermentation medium (L-phenylalanine high temperature and high drying sterilization) at 121°C for 20 minutes. After cooling, connect the fermentation tank, pass condensed water and sterile air with a ventilation volume of 0.5 V / (V·min), control the temperature of the fermentation tank at 28°C, and add sterilized L-phenylalanine. Inoculate 1% active Saccharomyces cerevisiae by flame burning at the inoculation port of the fermenter, and at the same time add 0.5g / L carotene at a speed of 350r / min for fermentation culture. After 4 hours, the speed was adjusted to 600r / min, the aseptic air ventilation rate was 1.0 V / V·min, and the control temperature remained unchanged a...

Embodiment 2

[0025] The biotransformation medium used in this example consists of 10g / L L-phenylalanine, 30g / L glucose, 5g / L K 2 HPO 4 , 5g / L MgSO 4 ·7H 2 O, 1g / L NaCl and the remainder of water, pH 6.5.

[0026] The above-mentioned fermentation medium containing 3.5L was sterilized by autoclaving at 121°C for 20 minutes. After cooling, connect the fermentation tank, pass condensed water and sterile air with a ventilation volume of 0.5 V / (V·min), control the temperature of the fermentation tank at 28°C, and add sterilized L-phenylalanine. Inoculate 1% active Saccharomyces cerevisiae by flame burning at the inoculation port of the fermenter, and add 0.5g / L vitamin E at the same time, and the rotation speed is 350r / min for fermentation culture. After 4 hours, the speed was adjusted to 600r / min, the ventilation rate of sterile air was 1.0 V / V·min, and the temperature was kept unchanged at 28°C. When both glucose and ethanol are consumed completely, the biotransformation is ended.

[0027] In the...

Embodiment 3

[0030] The biotransformation medium of this embodiment is calculated per liter, which consists of 10 g / L L-phenylalanine, 30 g / L glucose, and 5 g / L K 2 HPO 4 , 5g / L MgSO 4 ·7H 2 O, 1g / L NaCl and the remainder of water, pH 6.5.

[0031] The above-mentioned fermentation medium containing 3.5L was sterilized by autoclaving at 121°C for 20 minutes. Connect the fermentation tank, pass condensed water and sterile air with a ventilation volume of 0.5 V / (V·min), control the temperature of the fermentation tank at 28°C, and add sterilized L-phenylalanine. Inoculate 1% active Saccharomyces cerevisiae by flame burning at the inoculation port of the fermenter, and at the same time add 0.5 g / L of propyl gallate at a speed of 350r / min for fermentation culture. After 4 hours, the speed was adjusted to 600r / min, the ventilation rate of sterile air was 1.0 V / V·min, and the temperature was kept unchanged at 28°C. When both glucose and ethanol are consumed completely, the biotransformation is ende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com