Method for recovery of Kunitz and Bowman-Birk trypsin inhibitors from soybean whey

A technology of trypsin inhibition and soybean whey protein, which is applied in the direction of protease inhibitors, peptide preparation methods, chemical instruments and methods, etc., can solve complex and complicated processes and other problems, and achieve high purity, low equipment requirements, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

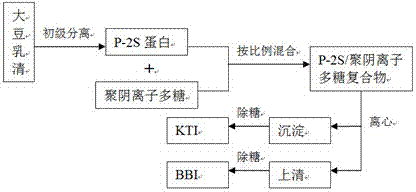

Method used

Image

Examples

Embodiment 1

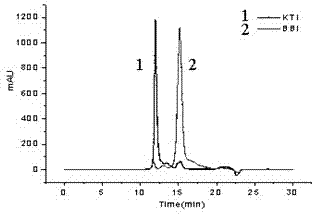

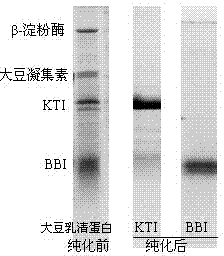

[0026] Adjust the soybean whey to pH 4.5, centrifuge (9500rpm, 30min) to remove the precipitate; adjust to pH 8.0 again, centrifuge (9500rpm, 30min), discard the precipitate, and collect the supernatant. Adjust the pH of the above supernatant to 4.5, measure 1L of the solution, add solid ammonium sulfate to 35% saturation according to the ammonium sulfate saturation table at 4-30°C, and centrifuge (9500rpm, 30min) to obtain KTI and BBI containing About 2.12g of crude protein was dissolved in 30mL of deionized water, dialyzed (molecular weight cut-off: 3500) for 36 hours to desalt, and the retentate was vacuum freeze-dried to prepare samples containing KTI and BBI inhibitors.

[0027]Accurately weigh 0.2g of the above primary separated KTI and BBI inhibitor samples and 0.2g of polyanionic polysaccharide powder respectively, add them into 100mL deionized water, stir until the two substances are completely dissolved, and prepare the mass concentration w / v of 0.2 % Homogeneous pro...

Embodiment 2

[0032] The soybean whey was adjusted to pH 4.5, centrifuged (9500rpm, 30min) to remove the precipitate; again adjusted to pH 8.5, centrifuged (9500rpm, 30min), the precipitate was discarded, and the supernatant was collected. Adjust the pH of the above supernatant to 4.7, measure 1.5L of the solution, add solid ammonium sulfate to 40% saturation according to the ammonium sulfate saturation table at 4-30°C, and centrifuge (9500rpm, 30min) to obtain KTI and About 3.35 g of crude BBI protein was dissolved in 40 mL of deionized water, dialyzed (molecular weight cut-off: 3500) for 48 hours, and vacuum freeze-dried to prepare the sample.

[0033] Accurately weigh 0.4g of the above primary separated KTI and BBI inhibitor samples and 0.4g of polyanionic polysaccharide powder respectively, add them to 100ml deionized water, stir until the two substances are completely dissolved, and prepare a homogeneous protein and polysaccharide with a mass concentration of 0.4%. solution. Both the ...

Embodiment 3

[0037] The soybean whey was adjusted to pH 4.8, centrifuged (9500rpm, 30min) to remove the precipitate; again adjusted to pH 9.0, centrifuged (9500rpm, 30min), the precipitate was discarded, and the supernatant was collected. Adjust the pH of the above supernatant to 4.8, measure 2L of the solution, add 30% saturated ammonium sulfate at 4-30°C according to the ammonium sulfate saturation table, and centrifuge to obtain about 0.356g of KTI and BBI protein crude products, add Dissolve in 10mL deionized water, dialyze (molecular weight cut-off: 3500) for 48 hours to desalt, and vacuum freeze-dry to prepare the sample.

[0038] Accurately weigh 0.15g of the above primary separated KTI and BBI inhibitor samples and 0.15g of polyanionic polysaccharide powder respectively, add to 100mL deionized water, stir until the two substances are completely dissolved, and prepare a homogeneous protein and polysaccharide with a mass concentration of 0.15% solution. Both the above soybean whey p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com