Preparation method of high-strength hydroxyapatite bone cement

A technology of hydroxyapatite and hydroxyapatite powder, applied in medical science, prosthesis, etc., can solve the problems of low compressive strength, large amount of heat release, limited operating time, etc., and achieve the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

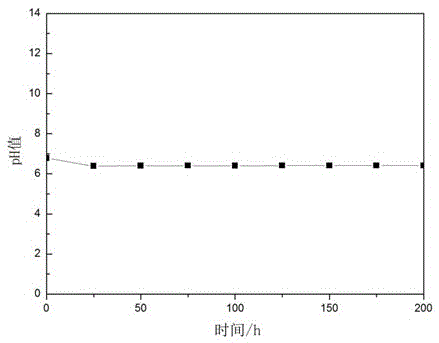

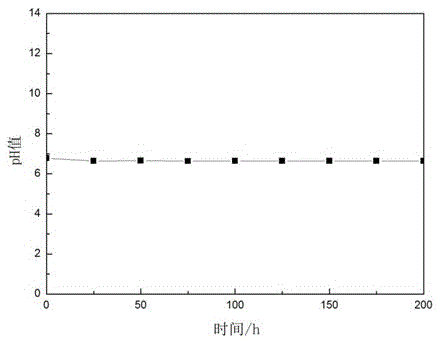

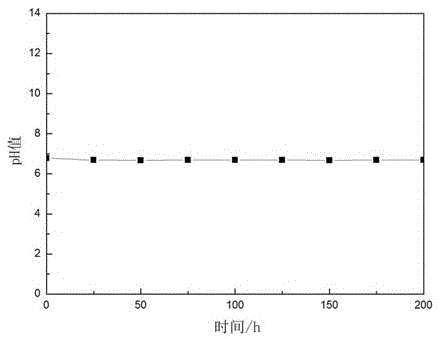

Image

Examples

Embodiment 1

[0032] step one:

[0033] 1) Weigh 10g of hydroxyapatite powder;

[0034] 2) Configure a phytic acid solution with a concentration of 10000ppm: weigh 1.43g of a phytic acid solution with a mass concentration of 70%, add distilled water to it to make 40ml, adjust its pH value to about 7.3 with 0.1mol / L NaOH solution, Finally, distill the solution to 50ml with distilled water to obtain 50ml of phytic acid solution with a concentration of 10000ppm;

[0035] 3) Put the weighed hydroxyapatite powder and the prepared phytic acid solution in a ball mill tank, and perform ball milling on the powder at room temperature to modify simultaneously, wherein the mass ratio of phytic acid to hydroxyapatite is 0.05 , the ball milling time is controlled to be 2h, and the slurry is obtained after ball milling;

[0036] Step two:

[0037] Suction filtration, distilled water washing and vacuum freeze-drying are performed on the slurry obtained after ball milling to obtain hydroxyapatite powder ...

Embodiment 2

[0044] step one:

[0045] 1) Weigh 10g of hydroxyapatite powder;

[0046] 2) configuration concentration is the phytic acid solution of 7000ppm, and operation steps are with embodiment 1;

[0047] 3) Put the weighed hydroxyapatite powder and the prepared phytic acid solution in a ball milling tank, and simultaneously modify the powder by ball milling at room temperature, wherein the mass ratio of phytic acid to hydroxyapatite is 0.035 , the ball milling time is controlled to be 4h, and the slurry is obtained after ball milling;

[0048] Step two:

[0049] Suction filtration, distilled water washing and vacuum freeze-drying are performed on the slurry obtained after ball milling to obtain hydroxyapatite powder surface-modified with 7000 ppm phytic acid solution after ball milling for 4 hours.

[0050] Step three:

[0051] 1) configuration mass concentration is 20% citric acid aqueous solution, operation steps are with embodiment 1.

[0052] 2) Mix the hydroxyapatite powder s...

Embodiment 3

[0056] step one:

[0057] 1) Weigh 10g of hydroxyapatite powder;

[0058] 2) Configure a phytic acid solution with a concentration of 1000ppm, and the operation steps are the same as in Example 1.

[0059] 3) Put the weighed hydroxyapatite powder and the prepared phytic acid solution in a ball mill tank, and simultaneously modify the powder by ball milling at room temperature, wherein the mass ratio of phytic acid to hydroxyapatite is 0.005 , the ball milling time is controlled to be 2h, and the slurry is obtained after ball milling;

[0060] Step two:

[0061] Suction filtration, distilled water washing and vacuum freeze-drying are performed on the slurry obtained after ball milling to obtain hydroxyapatite powder surface-modified by 1000 ppm phytic acid solution after ball milling for 2 hours.

[0062] Step three:

[0063] 1) configuration mass concentration is 10% citric acid aqueous solution, operation steps are with embodiment 1.

[0064] 2) Mix the hydroxyapatite po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com