Polyamide amino-functionalized magnetic polymer microsphere adsorbent and method for preparing and treating uranium-containing wastewater

A polyamide amine and microsphere adsorption technology, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the cumbersome separation process, limit large-scale industrial application, and complex synthesis process, etc. problems, to achieve the effect of simple preparation method, fast adsorption speed and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Mix 4.0g of glycidyl methacrylate, 2g of ethylene glycol dimethacrylate, 0.3g of acrylic acid and 50g of deionized water into the reaction flask; stir and heat to 50°C, pour into the reaction flask Add 50g Fe 3 o 4 Ferrofluid (Fe 3 o 4 The mass fraction of magnetic fluid is 5.0%), when the temperature rises to 70.0°C, add 20g of potassium peroxodisulfate aqueous solution (the mass fraction of potassium peroxodisulfate aqueous solution is 0.5%), when the temperature rises to 80°C, keep stirring 8h, after magnetic separation, freeze-dry for 12-24h to obtain epoxy-based magnetic polymer microspheres Fe 3 o 4 / P(GMA-AA-EGDMA).

Embodiment 2

[0042] (1) Take 0.5g Fe 3 o 4 / P(GMA-AA-EGDMA) was added to 100mL methanol, stirred at 25°C for 1h, added 7g of ethylenediamine, stirred at 80°C for 8h, magnetically separated, washed 3 times with 100mL methanol, and freeze-dried to obtain PAMAMG 0 -Fe 3 o 4 / (GMA-AA-EGDMA);

[0043] (2) Take 0.5g PAMAMG 0 -Fe 3 o 4 / (GMA-AA-EGDMA) was added to 100mL of methanol, after stirring at 25°C for 1h, 7g of methyl acrylate was added, stirred at 80°C for 8h, magnetically separated, and the product was washed 3 times with 100mL of methanol to obtain PAMAMG 0.5 -Fe 3 o 4 / (GMA-AA-EGDMA);

[0044] (3) Take 0.5g PAMAMG 0.5 -Fe 3 o 4 / (GMA-AA-EGDMA), added to 100mL of methanol, stirred at 25°C for 1h, added 7g of ethylenediamine, stirred at 80°C for 8h, magnetically separated, washed with 100mL of methanol for 3 times, and freeze-dried to obtain PAMAMG 1 -Fe 3 o 4 / (GMA-AA-EGDMA);

[0045] (4) Take 0.5g PAMAMG 1 -Fe 3 o 4 / (GMA-AA-EGDMA) was added to 100mL methanol, sti...

Embodiment 3

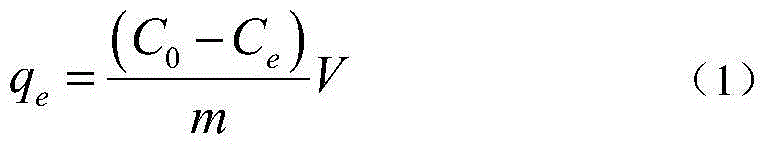

[0051] Accurately pipette 25mL, 50mg / L uranium standard solution and 150mL Erlenmeyer flask, use 1mol / L HCl solution, 1mol / L NaOH solution and 5mol / L NaOH solution to adjust the pH value of the solution to 5.0, add 0.0025 g of polyamidoamine-functionalized magnetic polymer microsphere adsorbent was adsorbed on a constant temperature oscillator at 25°C and 98r / min for 3h. Magnetic separation, supernatant was taken, and the concentration of uranium ions in the solution was measured by Arsenazo III spectrophotometry, and the adsorption amount at this time was calculated as 471.8 mg / g combined with formula (1).

[0052] The adsorption amount of uranium ions was calculated according to the following formula:

[0053] q e = ( C 0 - C e ) m V ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com