Synthesis method of nanorod-shaped AlPO4-15

A nanorod-like, synthetic method technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of many impurities in the product, and achieve the effect of prolonging the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

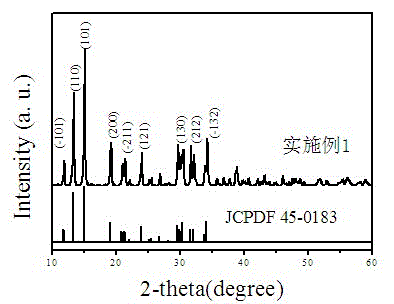

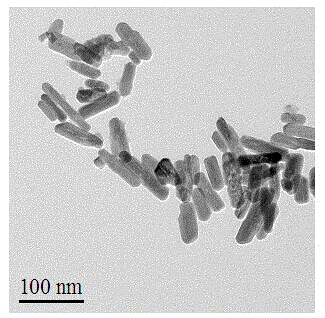

Embodiment 1

[0028] Dissolve 0.08mol aluminum nitrate and 1.21g urea in 80ml of deionized water, stir vigorously for 20min, then dissolve 0.08mol trisodium phosphate in the above solution, continue stirring for 30min, then transfer the solution to 100ml polytetrafluoroethylene In a stainless steel hydrothermal reaction kettle with ethylene lining, seal it, set the reaction temperature to 150°C, and close the reaction after 35 hours of reaction. When the reaction kettle is cooled to room temperature, use a vacuum filter to separate the white precipitate from the solution, and then put The white precipitate was washed with ethanol and distilled water. The obtained samples were dried at 60 °C for 24 h. Gained sample is done X-ray diffraction analysis (results such as figure 1 shown) and transmission electron microscopy analysis (results are shown in figure 2 shown). This embodiment makes nano-rod AlPO 4 -15 powder.

[0029] from figure 1 It can be seen that the XRD pattern of the sampl...

Embodiment 2

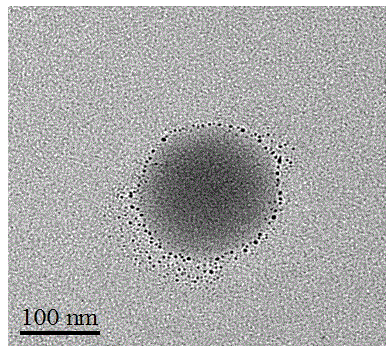

[0032] Dissolve 0.16mol aluminum nitrate and 2.0g urea in 80ml of deionized water, stir vigorously for 20min, then dissolve 0.16mol trisodium phosphate in the above solution, continue stirring for 30min, then transfer the solution to 100ml polytetrafluoroethylene In a stainless steel hydrothermal reaction kettle with ethylene lining, seal it, set the reaction temperature to 150°C, and close the reaction after 30 hours of reaction. When the reaction kettle is cooled to room temperature, use a vacuum filter to separate the white precipitate from the solution, and then put The white precipitate was washed with ethanol and distilled water. The obtained samples were dried at 60 °C for 24 h. The obtained samples were analyzed by transmission electron microscope (results are as follows: image 3 shown).

Embodiment 3

[0034] Dissolve 0.16mol aluminum nitrate and 2.0g urea in 80ml of deionized water, stir vigorously for 20min, then dissolve 0.16mol trisodium phosphate in the above solution, continue stirring for 30min, then transfer the solution to 100ml polytetrafluoroethylene In a stainless steel hydrothermal reaction kettle with ethylene lining, seal it, set the reaction temperature to 150°C, and close the reaction after 50 hours of reaction. When the reaction kettle is cooled to room temperature, use a vacuum filter to separate the white precipitate from the solution, and then put The white precipitate was washed with ethanol and distilled water. The obtained samples were dried at 60 °C for 24 h. The obtained samples were analyzed by transmission electron microscope (results are as follows: Figure 4 shown).

[0035] from Figure 4 It can be seen that the reaction time has a certain influence on the rod-shaped growth. When the reaction time is short, the obtained particles are tiny. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com