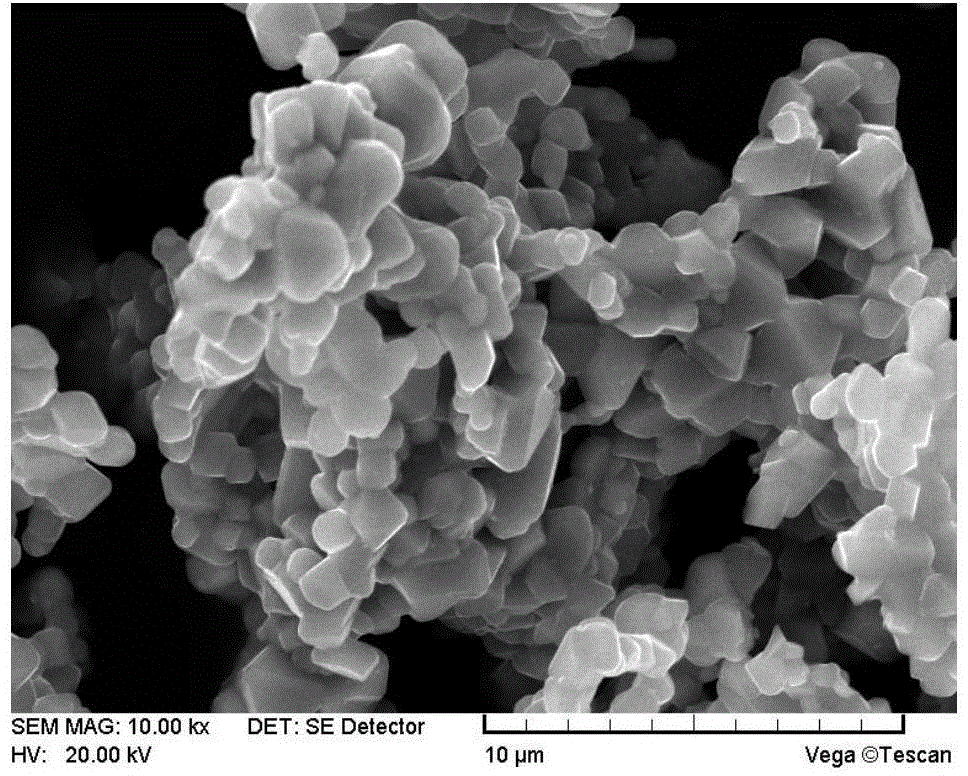

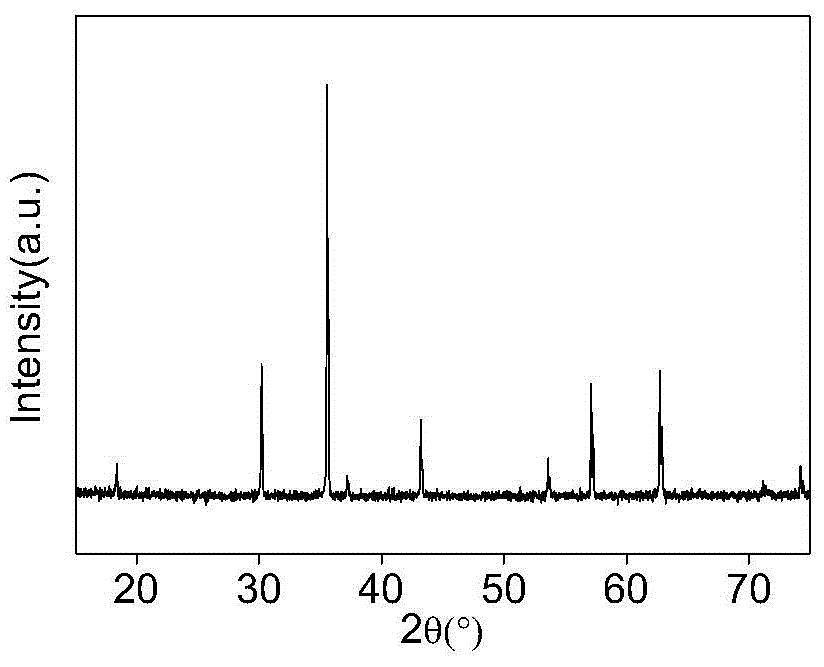

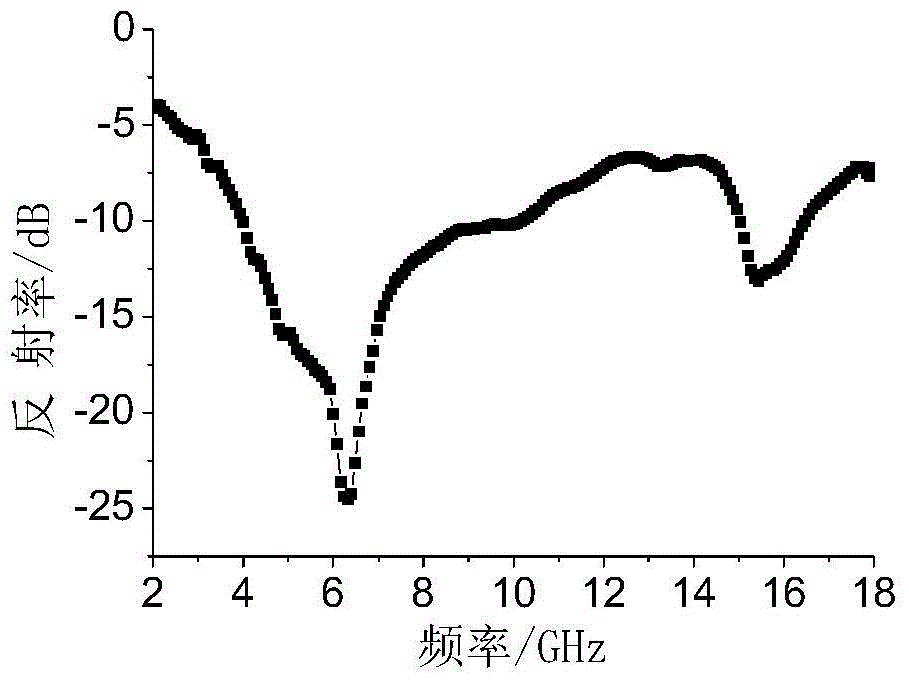

Manganese cerium doped nickel zinc ferrite nano wave absorbing powder and preparation method thereof

A nickel-zinc ferrite and nanotechnology, which is applied in the fields of radar wave absorption and functional materials, can solve the problems such as nano-absorbing powders that have not yet been seen, and achieve the effects of stable process, obvious absorption effect and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Accurately weigh 72.7g of nickel nitrate, 25g of manganese nitrate, 44.6g of zinc nitrate, 399.95g of iron nitrate, and 4.34g of cerium nitrate, and dissolve them in deionized water to form a mixed solution. Accurately weigh 384.3 g of citric acid and dissolve in the above solution, and stir fully to form a uniform and stable solution.

[0021] Step 2: Add 25% by mass concentrated ammonia water under continuous stirring to adjust the pH value of the solution to 7. Place the beaker containing the solution in an 80°C water bath environment, stir and heat continuously until a viscous wet gel is formed, then place it in a constant temperature drying oven at 120°C to dry until a xerogel is formed, and ignite it in the air to dry Glue to obtain the ferrite precursor;

[0022] Step 3: Calcining the precursor powder in a high-temperature sintering furnace at 1200°C for 3 hours, then cooling to room temperature with the furnace, and the product is manganese-cerium-doped...

Embodiment 2

[0024] Step 1: Accurately weigh 36.4g of nickel nitrate, 87.5g of manganese nitrate, 7.45g of zinc nitrate, 383.8g of iron nitrate, and 21.7g of cerium nitrate, and dissolve them in deionized water to form a mixed solution. Accurately weigh 384.3 g of citric acid and dissolve in the above solution, and stir fully to form a uniform and stable solution.

[0025] Step 2: Add concentrated ammonia water (25% by mass) under continuous stirring to adjust the pH value of the solution to 7. Place the beaker containing the solution in an 80°C water bath environment, stir and heat continuously until a viscous wet gel is formed, then place it in a constant temperature drying oven at 120°C to dry until a xerogel is formed, and ignite it in the air to dry Glue to obtain ferrite precursor.

[0026] Step 3: Calcining the precursor powder in a high-temperature sintering furnace at 1200°C for 3 hours, then cooling to room temperature with the furnace, and the product is manganese-cerium-doped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com