A kind of atmospheric pressure drying preparation method of mineral nanofiber airgel

A nanofiber, atmospheric drying technology, used in ceramic products, applications, household appliances, etc., to achieve the effect of reducing production costs, low thermal conductivity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

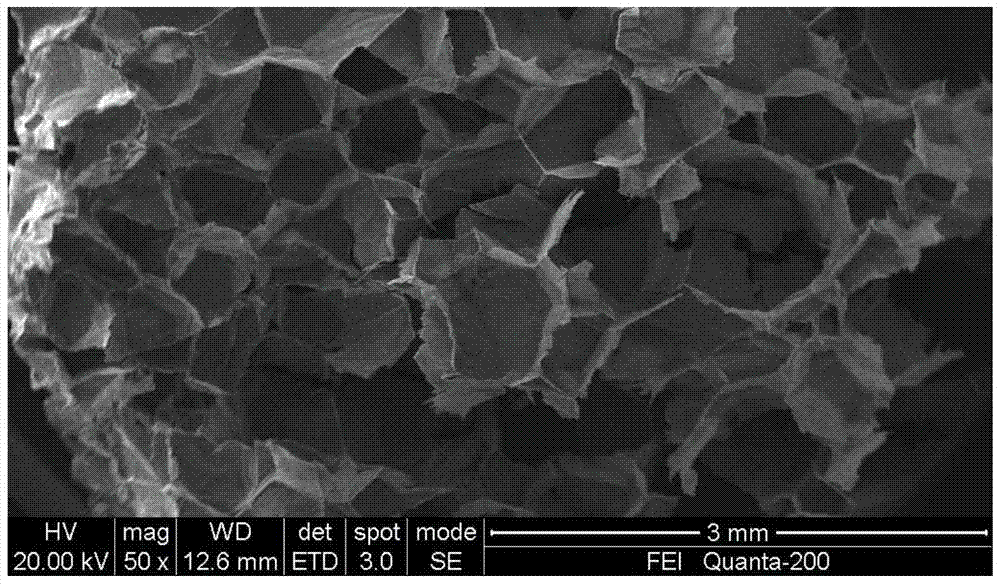

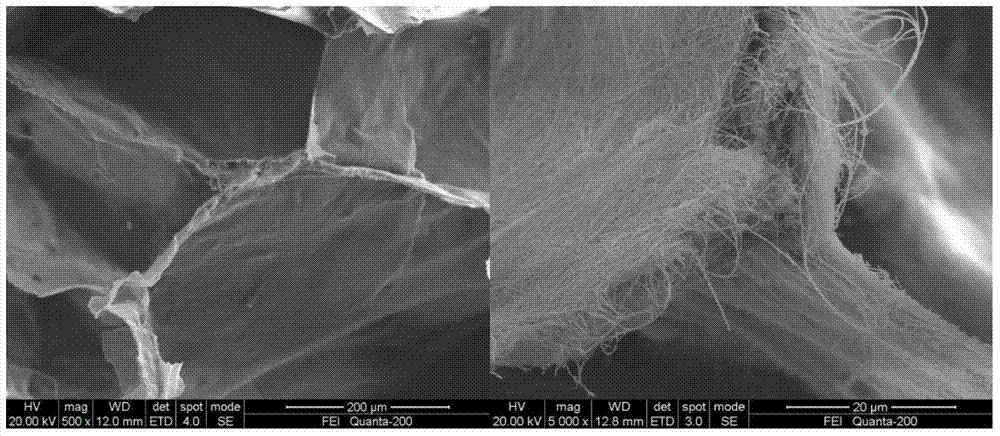

[0028] The purified chrysotile is used as raw material and mechanically emulsified under the action of a dispersant to obtain nanofiber suspension. The suspension is filtered, washed and dried to obtain a nanofiber filter cake. Weigh 2.0g of nanofibers, add them to 100ml of water, add 1.0g of sodium stearate and 0.02g of sodium polyacrylate, and stir well to form a uniform sol system with a viscosity of about 6000mPa·s. Then strong stirring is carried out, and air is introduced into the sol for foaming. After foaming, the foam volume is about 350ml, and the foaming ratio is 3.5 times. Then pour the foam into a square mold, vibrate it, maintain it at 90% humidity and 40°C for 10 hours, and then dry it at 55°C to obtain a block-shaped air condensation with a density of 0.017g / cm3 and a thermal conductivity of 0.028W / m·K Glue samples. internal honeycomb structure see figure 1 , the cell walls of the honeycomb are cross-linked by nanofibers, see figure 2 .

Embodiment 2

[0030] Using silicon oxide nanofibers obtained by acid leaching of chilliophilus nanofibers as raw materials, weigh 3.0 g of nanofibers, add them to 100 ml of water, add 0.5 g of sodium sulfosuccinate, and 5 ml of 30% H 2 o 2 and 0.1g polyvinyl alcohol, after fully stirring to form a uniform sol system, its viscosity is about 7800mPa·s. Then carry out strong stirring, and inject an appropriate amount of KI solution at the same time, so that the H 2 o 2 Decomposition produces O 2 The gas is foamed. After foaming, the foam volume is about 450ml, and the foaming ratio is 4.5 times. Then pour the foam into a square mold, vibrate, and dry at 60°C to obtain a bulk airgel sample with a density of 0.015g / cm3 and a thermal conductivity of 0.025W / m·K.

Embodiment 3

[0032] The purified sepiolite is used as a raw material, and the nanofiber suspension is obtained by adding a dispersant for grinding and emulsification. The suspension is filtered, washed and dried to obtain a nanofiber filter cake. Weigh 2.5g of nanofibers, add them to 100ml of water, add 1ml of cement foaming agent and 0.05g of hydroxypropyl methylcellulose, and stir well to form a uniform sol system with a viscosity of about 4000mPa·s. Then carry out strong stirring, and use the air pump to input air at the same time, and carry out foaming. After foaming, the foam volume is about 280ml, and the foaming ratio is 2.8 times. Then pour the foam into a square mold, vibrate, and dry at 50°C to obtain a bulk airgel sample with a density of 0.024g / cm3 and a thermal conductivity of 0.038W / m·K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com