Preparation method of hydroxyl-terminated styrene resin

A polystyrene resin and hydroxyl-terminated technology, which is applied in the field of preparation of hydroxyl-terminated polystyrene resin, can solve the problems of complex methods, high cost, fear of oxygen, etc., and achieve simple reaction conditions, fast reaction rate, and controllable products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

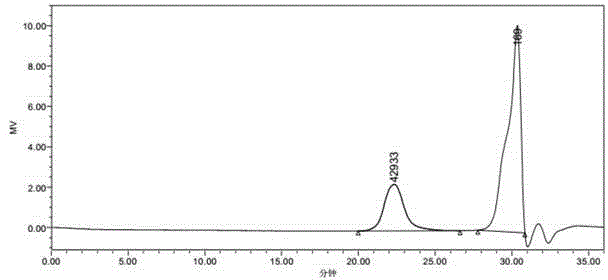

[0018] Add 5 grams of UV photoinitiator 2959 and 100 grams of refined styrene monomer into the UV reaction vessel, fill it with nitrogen at room temperature, seal it, place it in a UV oven, and adjust the UV light intensity to 150mW / cm 2 , after 20 seconds of light irradiation to stop the reaction, the unreacted styrene monomer was distilled off at 0.133kPa under reduced pressure at 70°C to obtain a hydroxyl-terminated polystyrene resin. Molecular weight as attached figure 1 .

Embodiment 2

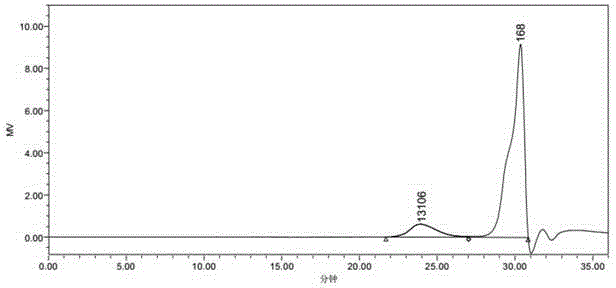

[0020] Add 15 grams of UV photoinitiator 2959 and 100 grams of refined styrene monomer to the UV reaction vessel, fill it with nitrogen at room temperature, seal it, place it in a UV oven, and adjust the UV light intensity to 100mW / cm 2 , after 40 seconds of light to stop the reaction, the unreacted styrene monomer was distilled off at 0.133kPa under reduced pressure and 70°C to obtain a hydroxyl-terminated polystyrene resin with molecular weight as attached figure 2 .

Embodiment 3

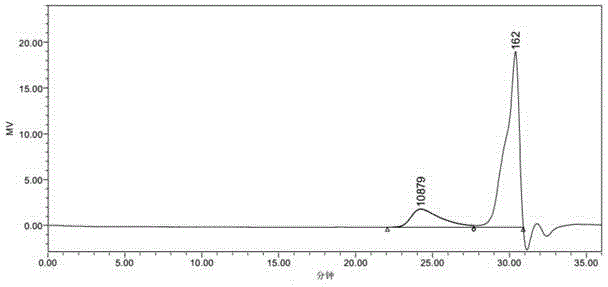

[0022] Add 30 grams of UV photoinitiator 2959 and 100 grams of refined styrene monomer to the UV reaction vessel, fill it with nitrogen at room temperature, seal it, place it in a UV oven, and adjust the UV light intensity to 50mW / cm 2 , after 80 seconds of light to stop the reaction, the unreacted styrene monomer was distilled off at 0.133kPa under reduced pressure and 70°C to obtain a hydroxyl-terminated polystyrene resin with molecular weight as attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com