Emulsifying agent for oil base drilling fluid and preparation method thereof

An oil-based drilling fluid and emulsifier technology, applied in the field of petroleum exploration, can solve the problems of difficult degradation of treatment agents and emulsifiers, poor dischargeability, outstanding treatment problems, etc., and achieve high electrical stability of the emulsion, low cost, and emulsification rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

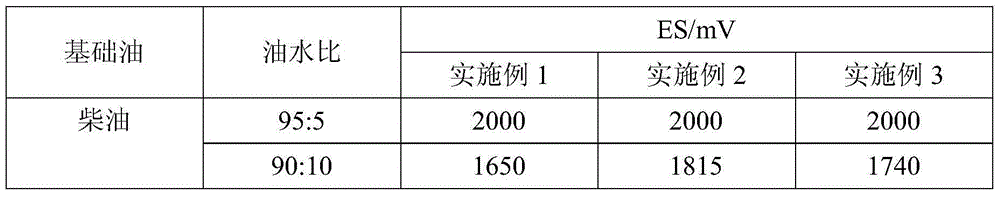

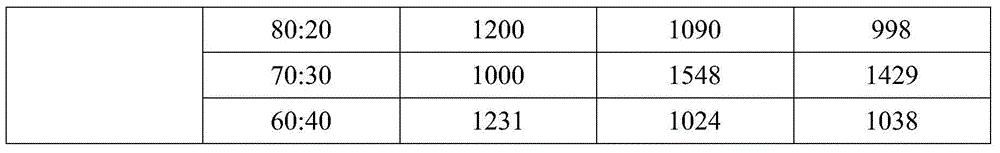

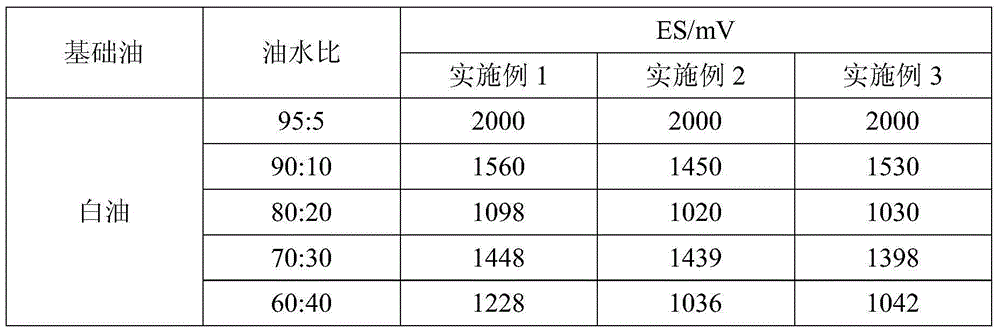

Embodiment 1

[0023] Present embodiment provides a kind of preparation method of emulsifier for oil-based drilling fluid, it comprises the following steps:

[0024] Put 30 parts of oleic acid, 2 parts of solid NaOH, and 200 parts of tap water into the autoclave in parts by mass, slowly feed nitrogen into the autoclave until the pressure is 0.5MPa, heat the autoclave to 100°C and stir for 3 hours After that, the material in the reaction kettle was completely dissolved to obtain a sodium oleate solution; 5 parts of CaCl were added to the sodium oleate solution 2 After continuing to stir for 2 hours, the reaction was terminated; after centrifuging the above mixed solution with a centrifuge, the separated product was dried at a low temperature (the temperature was lower than 70°C) to obtain solid calcium oleate, the purity of the calcium oleate is >90%;

[0025] Add 10 parts of tap water and 100 parts of soybean oil into the autoclave and stir evenly, slowly feed nitrogen into the autoclave, t...

Embodiment 2

[0028] Present embodiment provides a kind of preparation method of emulsifier for oil-based drilling fluid, it comprises the following steps:

[0029] Put 30 parts of palmitic acid, 2 parts of solid NaOH, and 200 parts of tap water into the autoclave in parts by mass, slowly feed nitrogen into the autoclave until the pressure is 0.6MPa, heat the autoclave to 90°C and stir for 2 hours After that, the materials in the reaction kettle were completely dissolved to obtain a sodium palmitate solution; 5 parts of MgCl were added to the sodium palmitate solution 2 After continuing to stir for 1 hour, the reaction was terminated; after centrifuging the above mixed solution with a centrifuge, the separated product was dried at a low temperature (the temperature was lower than 70° C.) to obtain solid magnesium palmitate. The purity of the magnesium palmitate was is >90%;

[0030] Add 10 parts of tap water and 100 parts of cottonseed oil into the autoclave and stir evenly, slowly pass ni...

Embodiment 3

[0033] Present embodiment provides a kind of preparation method of emulsifier for oil-based drilling fluid, it comprises the following steps:

[0034] Put 30 parts of lauric acid, 2 parts of solid NaOH, and 200 parts of tap water into the autoclave in parts by mass, slowly feed nitrogen into the autoclave until the pressure is 0.7MPa, heat the autoclave to 100°C and stir for 2 hours Finally, the material in the reaction kettle was completely dissolved to obtain a sodium laurate solution; 5 parts of BaCl were added to the sodium laurate solution 2 After continuing to stir for 1 hour, the reaction was terminated; after the above-mentioned mixed solution was centrifuged with a centrifuge, the product obtained by separation was dried at a low temperature (the temperature was lower than 70° C.) to obtain solid barium laurate. The purity of the barium laurate was is >90%;

[0035] Add 10 parts of tap water and 100 parts of coconut oil into the autoclave and stir evenly, slowly feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com