Lubricating oil having good oxidation resistance and specially used for dual-fuel engines

A dual-fuel engine, anti-oxidation technology, applied in the field of lubricating oil, can solve problems such as affecting engine power, engine ignition spark plug pollution, large lubricating oil evaporation loss, etc. The effect of oxidative power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

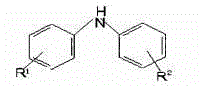

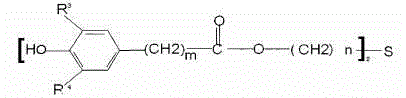

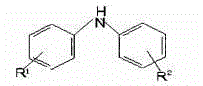

[0014] Example 1: A special lubricating oil for dual-fuel engines with good oxidation resistance, including 50 parts of base oil, 1.5 parts of nonylphenol polyoxyethylene ether, 1 part of polyvinyl ether, 11 parts of polyα-olefin, synthesized with high alkali number 10 parts of calcium sulfonate, 1 part of calcium alkylbenzene sulfonate, 1 part of thionyl octyl zinc salt, 2 parts of salicylate with a base value greater than 300mgKOH / g, 4 parts of glyceryl trilinoleate, trimethyldecane 1 part, 3 parts of sulfurized calcium alkylphenate, 1 part of calcium alkylbenzene sulfonate, 5 parts of acetophenone, 10 parts of glycerin, 6 parts of disodium edetate, 4 parts of modified polysiloxane, 0.7 parts of composite antioxidant (the composite antioxidant is composed of 0.5 parts of alkylated diphenylamine antioxidant and 0.2 part of thiophenol ester type antioxidant), metal reducing agent containing benzotriazole or thiadiazole Active agent 1 part.

Embodiment 2

[0015] Example 2: A special lubricating oil for dual-fuel engines with good oxidation resistance, including 55 parts of base oil, 2 parts of nonylphenol polyoxyethylene ether, 3 parts of polyvinyl ether, 15 parts of polyα-olefin, synthesized with high alkali value 12 parts of calcium sulfonate, 1.5 parts of calcium alkylbenzene sulfonate, 1.5 parts of thionyl octyl zinc salt, 3 parts of salicylate with a base value greater than 300mgKOH / g, 6 parts of glyceryl trilinoleate, trimethyldecane 3 parts, 5 parts of sulfurized calcium alkylphenate, 4 parts of calcium alkylbenzene sulfonate, 6 parts of acetophenone, 12 parts of glycerin, 8 parts of disodium edetate, 5 parts of modified polysiloxane, compounded 1 part of antioxidant (compound antioxidant consists of 0.5 part of alkylated diphenylamine antioxidant and 0.5 part of thiophenol ester type antioxidant), metal deactivation containing benzotriazole or thiadiazole 2 doses.

Embodiment 3

[0016] Example 3: A special lubricating oil for dual-fuel engines with good oxidation resistance, including 58 parts of base oil, 3 parts of nonylphenol polyoxyethylene ether, 5 parts of polyvinyl ether, 17 parts of polyα-olefin, synthesized with high alkali value 18 parts of calcium sulfonate, 2 parts of calcium alkylbenzene sulfonate, 2 parts of thionyl octyl zinc salt, 4 parts of salicylate with a base value greater than 300mgKOH / g, 7 parts of glyceryl trilinoleate, trimethyldecane 4 parts, 7 parts of sulfurized calcium alkylphenate, 5 parts of calcium alkylbenzene sulfonate, 8 parts of acetophenone, 14 parts of glycerin, 9 parts of disodium edetate, 5 parts of modified polysiloxane, compounded 2 parts of antioxidant (compound antioxidant consists of 1 part of alkylated diphenylamine antioxidant and 1 part of thiophenol ester antioxidant), metal deactivation containing benzotriazole or thiadiazole 2.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com