Low-cost and high-efficiency Al-Ti-C-Ce refining agent and preparation method thereof

A technology of al-ti-c-ce and refining agent, applied in the field of low-cost and high-efficiency Al-Ti-C-Ce refining agent and its preparation, can solve the problem of fluorine salt inclusions affecting the metallurgical quality of refining agent, fluorine Environmental pollution caused by compound gas, high preparation temperature, etc., to achieve the effect of shortening the reaction preparation time, lowering the preparation reaction temperature, and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

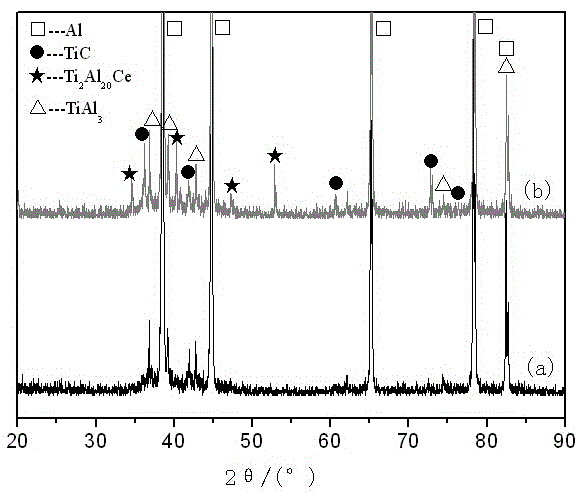

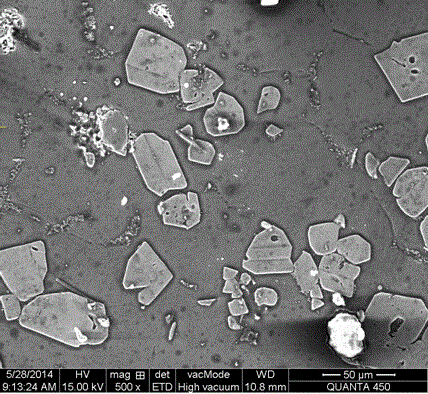

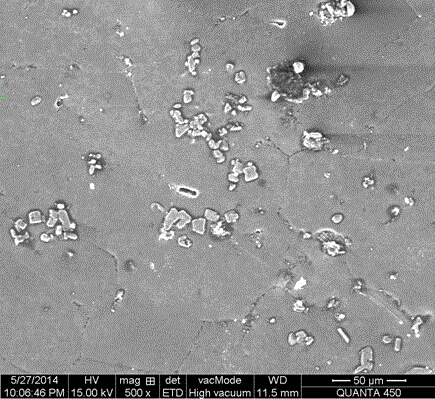

Image

Examples

Embodiment 1

[0040] The process of preparing Al-Ti-C-Ce refiner by thermal explosion method of aluminum melt is as follows:

[0041] (1) Raw material preparation, refiner is prepared from aluminum powder, titanium powder, graphite powder, aluminum ingot, cerium ingot. Weigh aluminum powder, titanium powder, graphite powder, aluminum ingot, and cerium ingot according to the composition requirements. The molar ratio of aluminum powder to titanium powder and graphite powder is required to be 1:0.8:0.4; the purity of aluminum ingot is 99.9%, and the purity of cerium ingot is 99.9%. ;Powder particle size: Al powder 200 mesh, Ti powder 350 mesh, C powder 400 mesh.

[0042] (2) Mix aluminum powder, titanium powder and graphite powder evenly, place the mixed powder in a mold, apply a pressure of 60MPa, and press it into a cylindrical block of φ25×50.

[0043] (3) Use graphite crucible for melting and graphite rods to stir to prevent Si pollution. Use a well-type resistance furnace to heat the ...

Embodiment 2

[0047] The difference between embodiment 2 and embodiment 1 is:

[0048] In step (1), the molar ratio of aluminum powder to titanium powder and graphite powder is 1:0.2:0.6;

[0049] In step (3), the cleaned aluminum ingot is heated to 780°C using a well-type resistance furnace. After the aluminum ingot is completely melted, the graphite bell jar is simultaneously pressed into the cerium ingot and the step (2) block; after the reaction is completed, statically Set aside for 8 minutes, manually stir the melt with a graphite rod every 1 minute, and stir 8 times;

[0050] In step (4), the preheating temperature of the filter box is 450°C.

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is:

[0053] In step (1), the molar ratio of aluminum powder to titanium powder and graphite powder is 1:0.4:0.1;

[0054] In step (3), the cleaned aluminum ingot is heated to 850°C using a well-type resistance furnace. After the aluminum ingot is completely melted, the graphite bell jar is simultaneously pressed into the cerium ingot and the step (2) block; after the reaction is completed, statically Set aside for 6 minutes, manually use a graphite rod to stir the melt once every 1 minute, and stir 6 times;

[0055] In step (4), the preheating temperature of the filter box is 550°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com