Porous adsorption film and preparation method thereof

A porous adsorption and colloid technology, applied in the polymer field, can solve the problems of water body being unable to drink normally, water body eutrophication, water quality corruption, etc., and achieve the effect of low price, large adsorption capacity and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

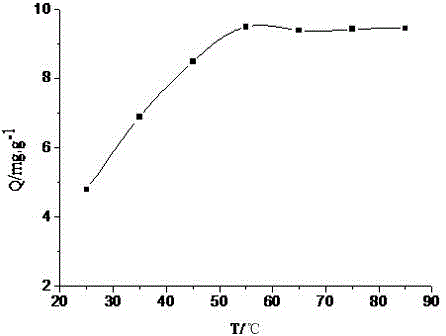

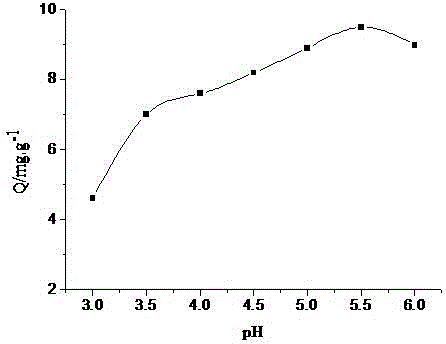

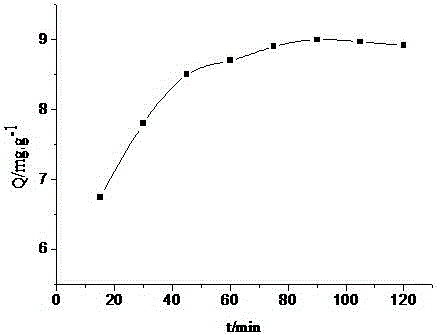

Image

Examples

Embodiment 1

[0035] 1) Preparation of chitosan sol: 1kg of chitosan was added to 100L of 2% acetic acid solution and stirred evenly to obtain chitosan sol;

[0036] 2) Preparation of β-cyclodextrin polymer: take 15kg of β-cyclodextrin polymer to crosslink with 4kg of sodium citrate, add 0.5kg of sodium dihydrogen phosphate dihydrate as a catalyst, heat for reaction for 5 hours, and dry, Can be obtained by washing and filtration;

[0037] 3) Preparation of dioxide peptide colloid: Mix 0.4L of tetrabutyl titanate and 1L of absolute ethanol to obtain mixed solution A; mix 25ml of absolute ethanol with 2ml of distilled water and 1ml of glacial acetic acid to obtain mixed solution B; drop the mixed solution B dropwise Add to the mixed liquid A, the volume ratio of the mixed liquid A and the mixed liquid B is 1:0.01, and stir to obtain the dioxide peptide colloid.

[0038] 4) Add 5kg of β-cyclodextrin polymer, 0.25L of vinyl triethoxysilane, 1kg of polyethylene glycol-20000, and 0.05L of titanium dio...

Embodiment 2

[0041] 1) Preparation of chitosan sol: take 10kg of chitosan and add it to 100L of 10% acetic acid solution, and stir evenly to obtain chitosan sol;

[0042] 2) Preparation of β-cyclodextrin polymer: take 20kg of β-cyclodextrin polymer to crosslink with 4kg of sodium citrate, add 0.5kg of sodium dihydrogen phosphate dihydrate as a catalyst, heat for reaction for 24 hours, and dry, Can be obtained by washing and filtration;

[0043] 3) Preparation of dioxide peptide colloid: mix 0.5L of tetrabutyl titanate and 0.5L of absolute ethanol to obtain mixed solution A; mix 50ml of absolute ethanol with 2ml of distilled water and 1ml of glacial acetic acid to obtain mixed solution B; Add dropwise to the mixture A, the volume ratio of the mixture A and the mixture B is 1:0.05, and stir to obtain the dioxide peptide colloid.

[0044] 4) Add 20kg of β-cyclodextrin polymer, 5kg of polyethylene glycol-20000, 0.5L of vinyl triethoxysilane, and 1L of titanium dioxide colloid to 100L of chitosan sol...

Embodiment 3

[0047] 1) Preparation of chitosan sol: prepare chitosan sol: take 5kg of chitosan and add it to 100L of 6% acetic acid solution, and stir evenly to obtain chitosan sol;

[0048] 2) Preparation of β-cyclodextrin polymer: take 17.5kg of β-cyclodextrin polymer to crosslink with 4kg of sodium citrate, add 0.5kg of sodium dihydrogen phosphate dihydrate as a catalyst, heat for 15 hours and dry , Washing, suction filtration available;

[0049] 3) Preparation of dioxide peptide colloid: Take 0.35L of tetrabutyl titanate and 0.5L of absolute ethanol and mix to obtain mixed solution A; mix 37.5ml of absolute ethanol with 2ml of distilled water and 1ml of glacial acetic acid to obtain mixed solution B; Add dropwise to the mixture A, the volume ratio of the mixture A and the mixture B is 1:0.03, and stir to obtain the dioxide peptide colloid.

[0050] 4) Add 12.5kg of β-cyclodextrin polymer, 3kg of polyethylene glycol-20000, 0.375L of vinyl triethoxysilane, and 0.5L of titanium dioxide colloid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com