Nano-metal or metal alloy catalyst and preparing method thereof

A nano-metal and metal alloy technology, which is applied in the field of nano-material application and catalysis, can solve the problems that the formation of three-dimensional materials has a huge impact, cannot form a three-dimensional graphene structure, and cannot obtain high quality, and achieve excellent catalytic performance, no support, good The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 is to prepare three-dimensional graphene airgel loaded Pt / Ni alloy catalyst:

[0034] 1) Dissolving graphene oxide powder in deionized water to obtain a uniformly dispersed graphene oxide aqueous solution, the concentration of the graphene oxide aqueous solution is 1 mg / mL.

[0035] 2) Add 25 microliters of PDDA aqueous solution with a mass fraction of 1.2% to 5 mL of the above graphene oxide aqueous solution, and obtain a PDDA-modified graphene oxide aqueous solution after ultrasonication for 30 min.

[0036] 3) K with a molar concentration of 0.1 mol / L 2 PtCl 4 and Ni(OAC) 2 Add 200 microliters of the PDDA-modified graphene oxide aqueous solution in 2), and ultrasonically disperse for 30 min.

[0037] 4) Under ultrasonic conditions, add 0.12 mmol of sodium borohydride reducing agent to the mixed solution obtained in 3), and continue ultrasonic response 10 min.

[0038] 5) Add 10 mg of ascorbic acid into the mixed solution in 4), and disperse by ult...

Embodiment 2

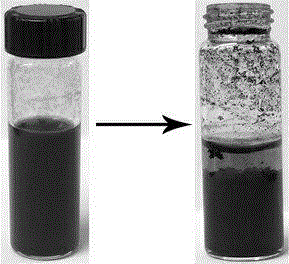

[0043] The steps of embodiment 2 are similar to embodiment 1, but the amount of PDDA is raised to 100 microliters from 25 microliters, and others remain unchanged; figure 2 For its digital photos, it can be seen from the digital photos that when the amount of PDDA increases to 100 ml, a suspension is formed, and a three-dimensional hydrogel structure cannot be formed, so a three-dimensional airgel structure cannot be formed in the end. This is because the excessive PDDA combines all the groups of graphene oxide, making the distance between the formed graphene sheets far away, so that it cannot be assembled into a three-dimensional graphene hydrogel structure.

Embodiment 3

[0045] The step of embodiment 3 is similar to embodiment 1, but the amount of sodium borohydride added in every milliliter of graphene oxide solution increases to 0.5 mmol , and others remain unchanged.

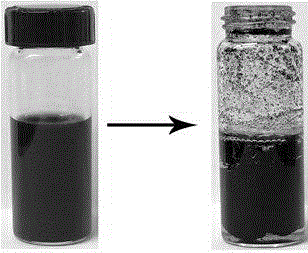

[0046] image 3 Its digital photo shows that a large number of fragments are accumulated in the small bottle, but the three-dimensional hydrogel structure cannot be formed, and the three-dimensional airgel structure cannot be formed; this is because after too much sodium borohydride, the reaction It is too strong, and graphene oxide also begins to be reduced to graphene, which leads to an instant decrease in water solubility and precipitation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com