Organic-inorganic composite paint and preparation method thereof

A composite and inorganic technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of poor heat resistance, easy to mold and rot, poor stain resistance, etc., and achieve the effect of excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

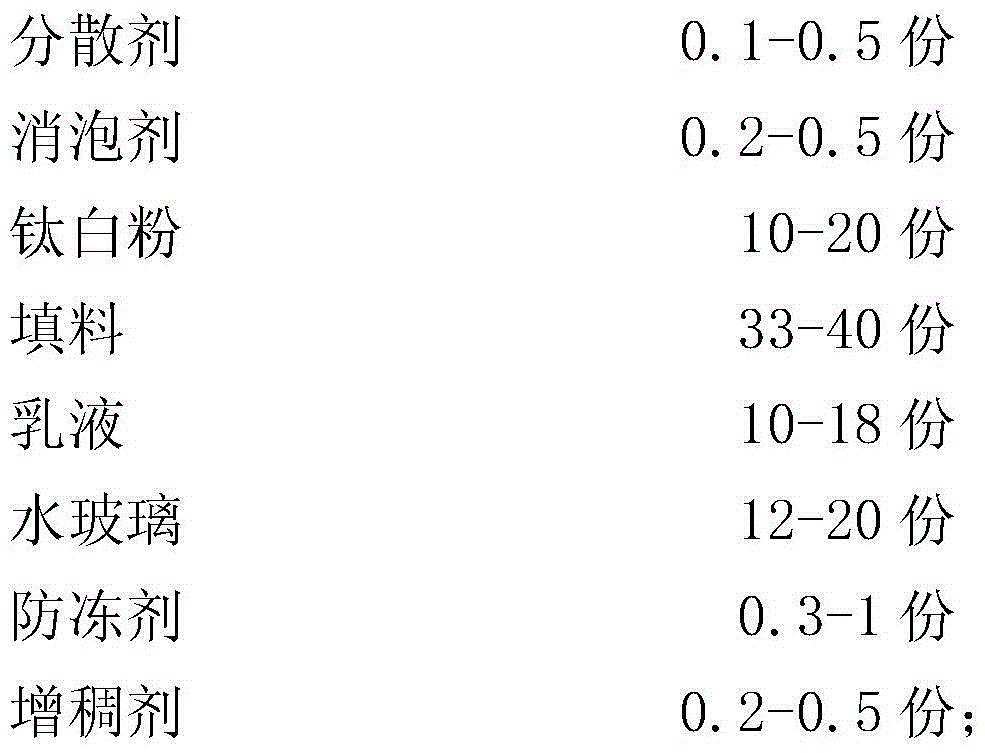

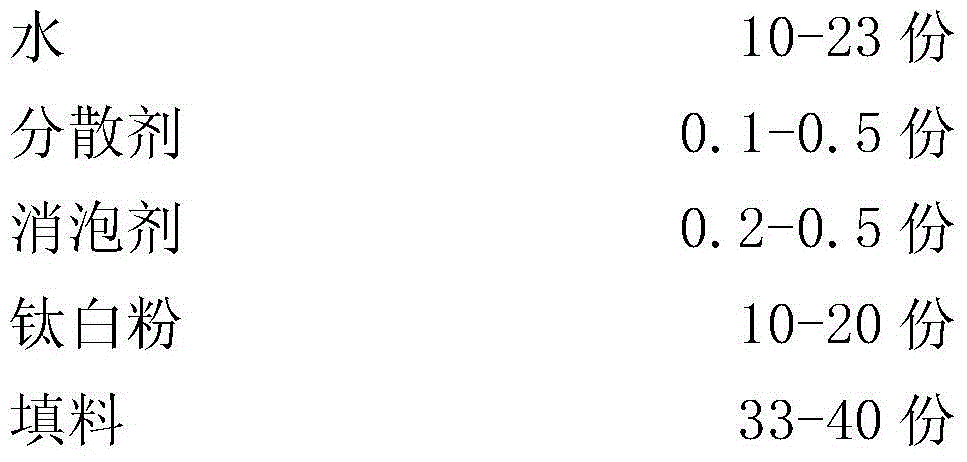

[0025] An organic-inorganic composite coating is prepared from the following components and parts by weight ratio:

[0026]

[0027]

[0028] A kind of preparation method of organic-inorganic composite coating, it comprises the steps:

[0029] (1) After mixing water and thickener, disperse for 3-5 minutes at a speed of 300-600 rpm;

[0030] (2) Add defoamer and dispersant while dispersing at a speed of 300-600 rpm, and then disperse at a speed of 800-1200 rpm for 2-4 minutes;

[0031] (3), then add titanium dioxide and filler while dispersing at a speed of 800-1200 rpm, and then disperse at a speed of 1800-2200 rpm for 18-22 minutes;

[0032] (4) Add emulsion and antifreeze at a speed of 400-600 rpm, and then disperse for 2-4 minutes at a speed of 400-600 rpm;

[0033] (5) Add water glass while dispersing at a speed of 400-600 rpm, and then disperse at a speed of 800-1000 rpm for 4-6 minutes until the mixed liquid is uniform.

[0034] The filler described in the above...

Embodiment 1

[0036] Embodiment 1: An organic-inorganic composite coating is prepared from the following components and parts by weight ratio:

[0037]

[0038]

[0039] A kind of preparation method of organic-inorganic composite coating, it comprises the steps:

[0040] (1) After mixing 16 parts of water and 0.3 part of hydroxyethyl cellulose, disperse at a speed of 500 rpm for 4 minutes;

[0041] (2) Add 0.3 parts of mineral oil defoamer and 0.2 parts of wetting and dispersing agent while dispersing at a speed of 500 rpm, and then disperse for 3 minutes at a speed of 1000 rpm;

[0042] (3), then add 15 parts of titanium dioxide, 31 parts of heavy calcium, 3.7 parts of barite and 4 parts of washed soil while dispersing at a speed of 1000 rpm, and then disperse at a speed of 2000 rpm for 20 minutes;

[0043] (4), add 12 parts of emulsion and 0.3 parts of antifreeze at a speed of 500 rpm, and then disperse for 3 minutes at a speed of 500 rpm;

[0044] (5) Add 17 parts of water glass ...

Embodiment 2

[0046] Embodiment 2: An organic-inorganic composite coating is prepared from the following components and parts by weight ratio:

[0047]

[0048]

[0049] A kind of preparation method of organic-inorganic composite coating, it comprises the steps:

[0050] (1) After mixing 10 parts of water and 0.25 parts of hydroxyethyl cellulose, disperse at a speed of 300 rpm for 5 minutes;

[0051] (2) Add 0.5 part of mineral oil defoamer and 0.5 part of wetting and dispersing agent while dispersing at a speed of 300 rpm, and then disperse at a speed of 800 rpm for 4 minutes;

[0052] (3), then add 20 parts of titanium dioxide, 26 parts of heavy calcium, 1 part of barite and 6 parts of washed soil while dispersing at a speed of 800 rpm, and then disperse at a speed of 1800 rpm for 22 minutes;

[0053] (4), add 15 parts of emulsion and 0.5 part of antifreeze at 400 rpm, then disperse for 4 minutes at 400 rpm;

[0054] (5) Add 20 parts of water glass and 0.25 parts of polyurethane t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com