A kind of heavy oil hydrogen conversion method

A hydrogen conversion and heavy oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems such as difficult to achieve the upgrading effect, and achieve the effect of reducing the amount of external dumping, reducing costs, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

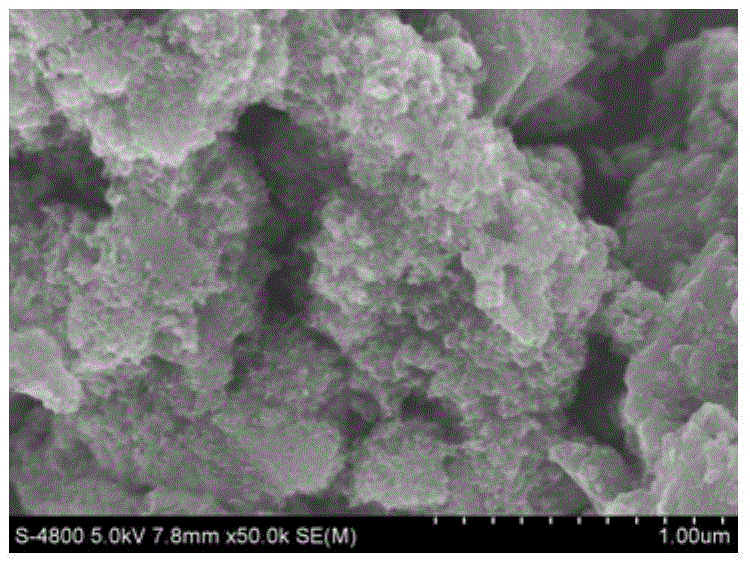

[0036] In the method provided by the present invention, the preparation method of the hydrothermal cracking catalyst comprises: contacting the metal source and the nonmetal source with a sulfidation agent in the presence of a solvent and under sulfidation reaction conditions to obtain the hydrothermal cracking catalyst. Wherein, the metal source is a substance containing V, Ni and lanthanide metal elements and / or Group VIB metal elements, the non-metal source is a substance containing carbon, and the metal source, non-metal source and vulcanizing agent The amount of the metal element contained in the solid product obtained after contacting contains 2-15% by weight of metal elements and 85-98% by weight of non-metallic elements, and based on the weight of the metal elements, the metal elements of more than 95% by weight are V, Ni and lanthanide metal elements and / or Group VIB metal elements; based on the weight of non-metal elements, more than 95% by weight of the non-metal elem...

Embodiment 1~3

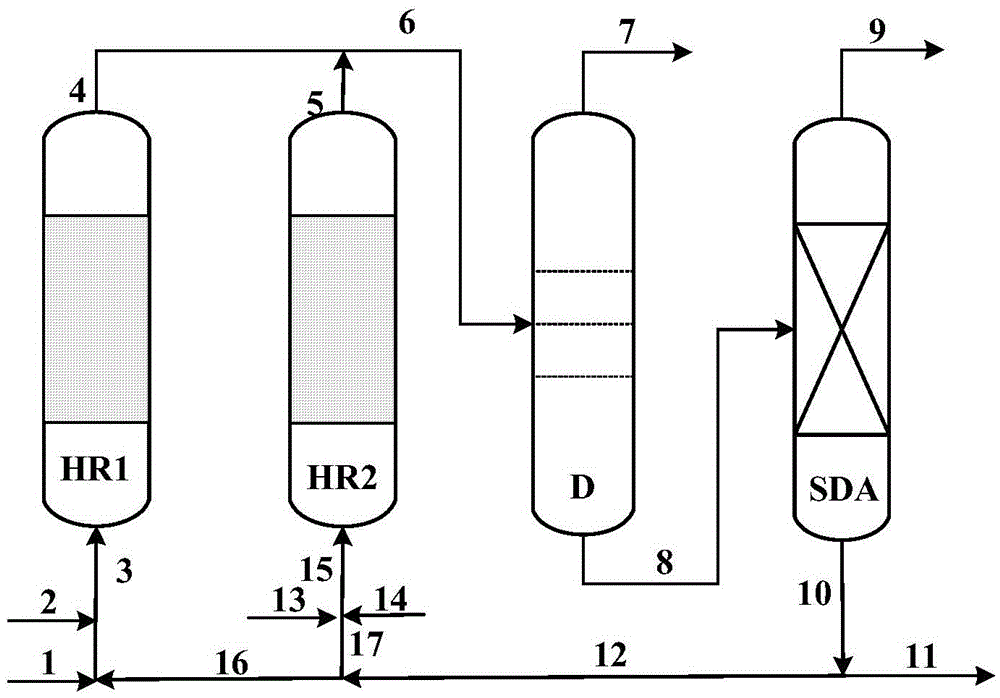

[0058] The experimental flow chart is attached figure 1 As shown, the residual oil is transported to the preheating furnace through the pump, preheated to 400°C, mixed with hydrogen and circulating deoiled asphalt, and enters the first reactor for reaction. The reaction product of the first reactor enters the separation unit D, and the fraction is separated Oil products and residual oil, the residual oil enters the solvent deasphalting tower for separation to obtain deasphalted oil and deoiled asphalt, wherein the catalyst-containing deoiled asphalt, catalyst, and hydrogen enter the second reactor, and the reaction product of the second reactor enters the separation unit D A small amount of deoiled bitumen from the solvent deasphalting unit is thrown out to maintain the catalyst concentration and activity in the second reactor to be stable. Analyze and measure the content of toluene insoluble matter in the generated oil, and calculate the yield of distillate oil (including DAO...

Embodiment 4~5

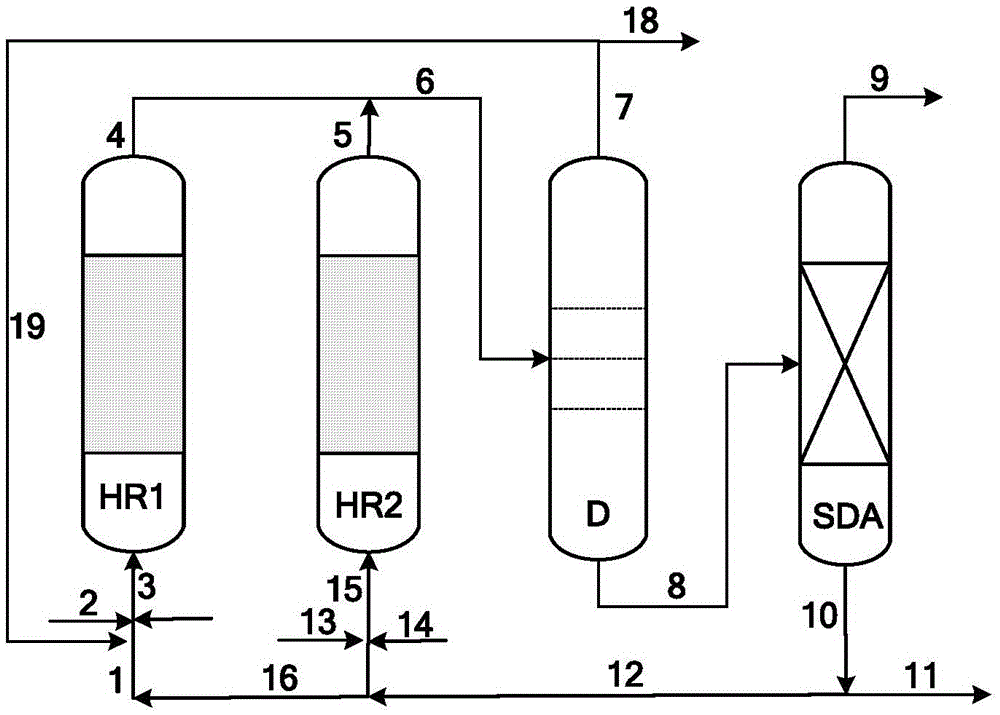

[0060] Use as attached figure 2 The device and process shown are different from Example 1 in that the raw materials entering the first reactor are heavy oil raw materials and heavy wax oil, and the reaction products of the first reactor and the second reactor enter the separation unit D for separation to obtain light fractions oil, heavy wax oil and residual oil, part of the heavy wax oil is recycled back to the first reactor for reaction. The experimental conditions and reaction results are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com