Vertical coupled feeding structure applied to millimeter-wave microstrip antenna

A microstrip antenna, vertical coupling technology, applied in the direction of the structure connection of the antenna grounding switch, the antenna grounding device, the structure of the radiating element, etc., can solve the problems of interfering with the antenna pattern and reducing the gain, reducing the plane cross-sectional area of the system, avoiding the High inductance value, effect of reducing effective dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The substantive features and remarkable progress of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is by no means limited to the embodiments.

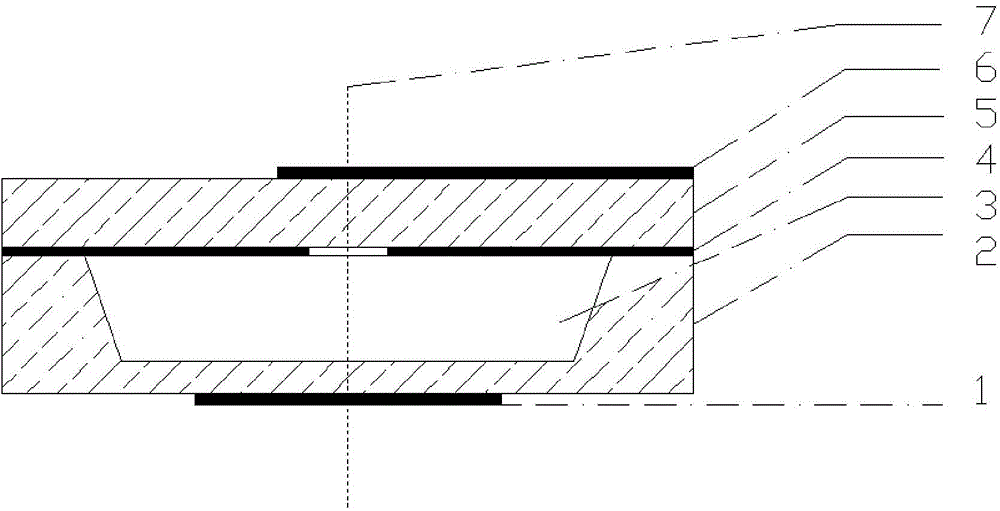

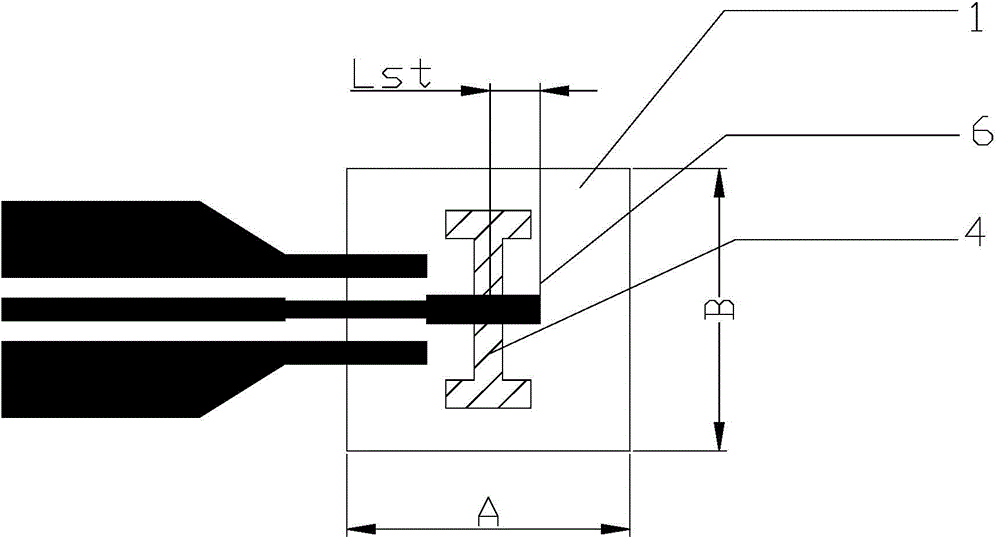

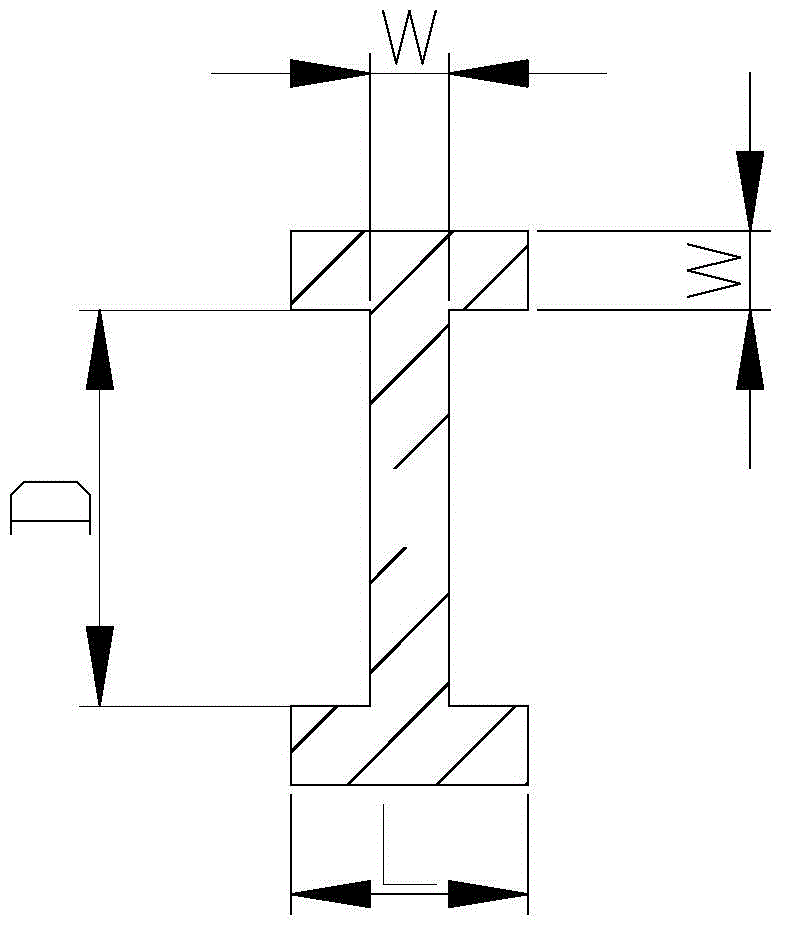

[0020] Embodiments of the present invention relate to a vertically coupled feeding structure applied to millimeter wave antennas, such as figure 1 As shown, the provided vertical feed structure includes a microstrip patch antenna 1, a bottom dielectric substrate substrate 2, a substrate cavity structure 3, a ground plane 4 with a gap, a top dielectric substrate substrate 5, a common Surface waveguide to microstrip feeder 6.

[0021] like figure 1 As shown, the microstrip patch antenna 1 is manufactured on the lower surface of the underlying dielectric substrate by using the semiconductor process through the process steps of sputtering-photolithography-electroplating-corrosion. The coplanar waveguide-to-microstrip feeder 6 and the ground plate 4 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com