Polyrhachis vicina roger extract as well as preparation method and application thereof

A technology of imitating black spiny ants and extraction methods, which is applied in the direction of drug combination, medical raw materials derived from arthropods, metabolic diseases, etc., can solve the problems of abnormal liver function, waste of resources, low yield, etc., and achieve energy saving and emission reduction , low cost, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

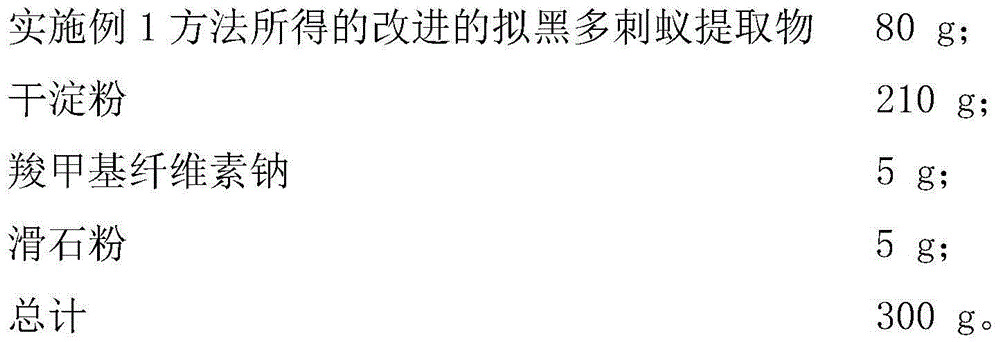

[0037] The preparation of the improved Pseudomonas spinosa extract of embodiment 1

[0038] 1000 g of Pseudomonas spinosa ants powder, 95% ethanol heating reflux extraction 3 times, 4 L each time, combined extracts, recovered ethanol under reduced pressure to obtain primary oil. Extract with petroleum ether (the boiling point of petroleum ether is 60°C-90°C), and recover the solvent to obtain 150g of petroleum ether. The petroleum ether part passes through the silica gel chromatography column, within 0 to 60h, the volume ratio of petroleum ether: ethyl acetate is eluted from the mobile phase gradient of 100%: 0% → 80%: 20%, and 121 fractions (500m L / part), the 11-22 fractions were recrystallized to obtain 20g of component I; the 28-36 fractions were subjected to repeated silica gel column chromatography and recrystallization to obtain 42g of component II, and the 40-48 fractions were repeatedly recrystallized to obtain components III 14g. Combine components I, II, and III a...

Embodiment 2

[0039] The preparation of the improved Pseudomonas spinosa extract of embodiment 2

[0040] 1000 g of Pseudomonas spinosa ants powder, 75% ethanol heating reflux extraction 3 times, 4 L each time, combined extracts, recovered ethanol under reduced pressure to obtain primary oil. Extract with petroleum ether (the boiling point of petroleum ether is 60°C-90°C), and recover the solvent to obtain 120g of petroleum ether. Petroleum ether parts passed through the silica gel column, within 0 to 55h, the volume ratio of petroleum ether: ethyl acetate was eluted from the mobile phase gradient of 100%:0% → 80%:20%, and 121 fractions (500m L / part), the 11-22 fractions were recrystallized to obtain 15g of component I; the 28-36 fractions were subjected to repeated silica gel column chromatography and recrystallization to obtain 30g of component II, and the 40-48 fractions were repeatedly recrystallized to obtain components III 10g. Combine components I, II, and III and purify with petr...

Embodiment 3

[0041] The preparation of the improved Pseudomonas spinosa extract of embodiment 3

[0042] 1000 g of Pseudomonas spinosa ants powder, 56% ethanol heating reflux extraction 3 times, 4 L each time, combined extracts, recovered ethanol under reduced pressure to obtain primary oil. Extract with petroleum ether (the boiling point of petroleum ether is 60°C-90°C), and recover the solvent to obtain 18g of petroleum ether. Petroleum ether parts passed through the silica gel column, within 0 to 65h, the volume ratio of petroleum ether: ethyl acetate was eluted from the mobile phase gradient of 100%:0% → 80%:20%, and 121 fractions (500m L / part), the 11-22 fractions were recrystallized to obtain 15g of component I; the 28-36 fractions were subjected to repeated silica gel column chromatography and recrystallization to obtain 10g of component II, and the 40-48 fractions were repeatedly recrystallized to obtain components III 5g. Combine components I, II, and III and purify with petrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com