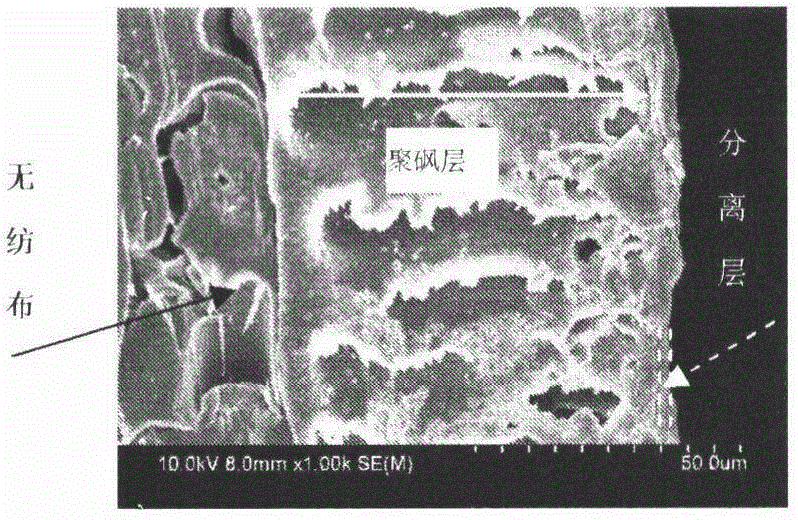

Composite membrane with hydrophilic separation layer

A separation layer and composite membrane technology, applied in the field of composite membranes, can solve the problems of low modifier density, large time consumption, complicated and cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

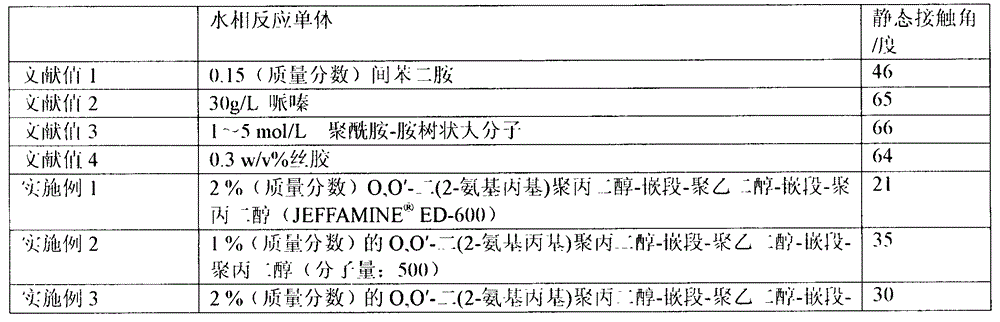

Embodiment 1

[0015] Preparation of aqueous phase reaction liquid, containing 2% (mass fraction) O in the aqueous phase reaction liquid, O'-bis (2-aminoendyl) polypropylene glycol-block-polyethylene glycol-block-polypropylene glycol (molecular weight : 500), 0.05% (mass fraction) of sodium lauryl sulfate; prepare the organic phase reaction solution, the organic phase reaction liquid is the n-hexane solution of 0.5% (mass fraction) trimesoyl chloride. The base film is a polysulfone flat film scraped on a non-woven fabric. First, at 25°C, immerse the base film in the aqueous phase reaction solution for 20 minutes, take it out, immerse it in the organic phase reaction solution, and take out the interfacial polymerization time for 5 minutes, take it out, wash the composite film with deionized water, and then put the composite film at a temperature of 40°C The film was dried for 3 minutes, and finally dried at room temperature. The static contact angle was measured (SL200KB optical contact angl...

Embodiment 2

[0017] Preparation of aqueous phase reaction liquid, containing 1% (mass fraction) O in the aqueous phase reaction liquid, O'-two (2-aminopropyl) polypropylene glycol-block-polyethylene glycol-block-polypropylene glycol (molecular weight : 500), 0.05% (mass fraction) of sodium lauryl sulfate; prepare the organic phase reaction solution, the organic phase reaction liquid is the n-hexane solution of 0.5% (mass fraction) trimesoyl chloride. The polyethersulfone porous membrane is used as the base membrane. First, at 25°C, immerse the polyethersulfone base membrane in the aqueous phase reaction solution for 20 minutes, take it out, immerse it in the organic phase reaction solution, and take out the interfacial polymerization time for 5 minutes, take it out, wash the composite membrane with deionized water, and then in 40°C Dry the composite film for 3 minutes, and finally dry it at room temperature. The static contact angle was measured (SL200KB optical contact angle / interface te...

Embodiment 3

[0019] Preparation of aqueous phase reaction liquid, containing 2% (mass fraction) O in the aqueous phase reaction liquid, O'-two (2-aminopropyl) polypropylene glycol-block-polyethylene glycol-block-polypropylene glycol (molecular weight : 800), 0.05% (mass fraction) of sodium lauryl sulfate; prepare the organic phase reaction solution, the organic phase reaction liquid is 0.3% (mass fraction) trimesoyl chloride and 0.3% (mass fraction) isophthaloyl dichloride Formyl chloride in n-hexane. The polysulfone porous membrane is used as the base membrane. First, at 25°C, immerse the polyethersulfone base membrane in the aqueous phase reaction solution for 10 minutes, take it out, immerse it in the organic phase reaction solution, take out the interfacial polymerization time for 6 minutes, take it out, wash the composite membrane with deionized water, and then immerse it in the temperature of 60°C The composite film was dried for 6 minutes, and finally dried at room temperature. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com