Method for removing bromine from disperse dye wastewater

A technology for disperse dyes and wastewater, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of no treatment plan, etc., and achieve the effects of small solid waste output, corrosion avoidance, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

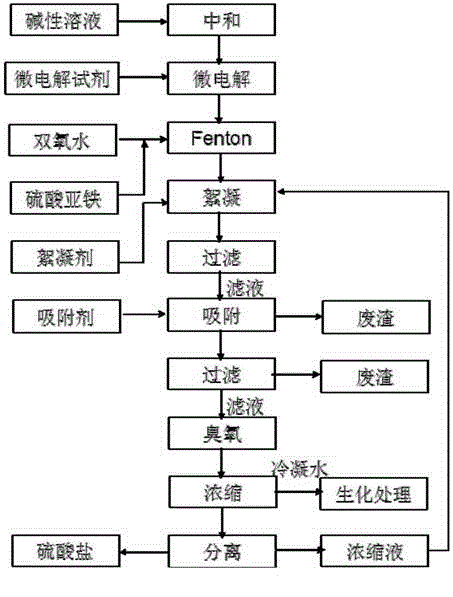

Method used

Image

Examples

Embodiment 1

[0038] The color of disperse red 60 hydrolysis mother liquor wastewater is reddish black, containing bromide ion=3089mg / L, sulfuric acid about 35%, COD=12025mg / L.

[0039] Adjust wastewater pH=4 with liquid ammonia; add 0.5% FeSO 4 ·7H 2 O and 1.0% hydrogen peroxide (based on the mass of the disperse red 60 hydrolyzed mother liquor wastewater), the temperature is controlled between 40-50°C, and the reaction is stirred for 1 hour; after the reaction, add 0.26% PAM (polyacrylamide) solution to the wastewater , and then adjust the pH to 8 with ammonia water, first stir quickly for 0.5 min, then slowly stir for 20 min, and filter. Then add 0.2% activated carbon, stir for 0.5h, and filter. The filtrate is colorless and transparent, COD in the filtrate=5982mg / L, Br - = 8mg / L. The filtrate was adjusted to pH 5.5 with concentrated sulfuric acid and concentrated under reduced pressure. Concentrated 1.7 times, COD in the concentrate=9705mg / L, COD in the condensate=1053.4mg / L, NH 3...

Embodiment 2

[0060] The color of the disperse red 3B hydrolysis mother liquor wastewater is dark purple, containing bromide ions=2480mg / L, sulfuric acid about 41%, COD=16025mg / L. Add ammonia water (mass concentration: 25-28%) to the wastewater, and adjust the pH of the wastewater to about 2; add 0.3% activated carbon, 2% iron powder, and 0.2% copper to the neutralized wastewater, and stir at room temperature for reaction 4h; add 0.8% hydrogen peroxide to the wastewater after micro-electrolysis, control the temperature between 40-50°C, and stir for 1h; add 0.11% PAM solution to the wastewater after Fenton oxidation, and then use ammonia water (mass concentration of 28%) to adjust pH=9, stir and flocculate for 0.3h and then filter. The filtrate was light yellow, and 0.2% activated carbon was added for adsorption for 0.5h, and then suction filtered. The filtrate is colorless and transparent, the filtrate COD=5868mg / L, Br - =34mg / L; the wastewater after flocculation and decolorization was ad...

Embodiment 3

[0069] The hydrolyzed bromination wastewater of Disperse Blue 56 contains bromine 3588mg / L, acid 45%, COD=56433mg / L. Add ammoniacal liquor (mass concentration is 25~28%) in waste water, the pH of waste water is adjusted to about 4; Add iron-carbon reagent and 0.2% copper in the waste water after neutralization, normal temperature stirring reaction 4h; 1.5% hydrogen peroxide was added to the waste water, the temperature was controlled between 40-50° C., and the reaction was stirred for 1 hour. Add 0.25% PAM solution to the wastewater after Fenton oxidation, adjust pH to 9 with ammonia water (mass concentration: 25-28%), slowly stir and flocculate for 0.5 h, and filter. The filtrate was light yellow, and 0.5% activated carbon was added for adsorption for 0.5h, and then suction filtered. The filtrate is colorless and transparent, the filtrate COD=10468mg / L, Br - = 34 mg / L. Finally, pass ozone for 2 hours, COD drops to 1214mg / L, Br-=5mg / L. The wastewater after flocculation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com