Gaseous membrane, preparation method thereof and method for preparing bromine-free or low-bromine saline water

A gaseous membrane and brine technology, applied in the field of brine debromination and gaseous membrane, can solve the problems of low bromine removal rate, large floor area, high operating cost, etc., and achieve high porosity, strong corrosion resistance, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

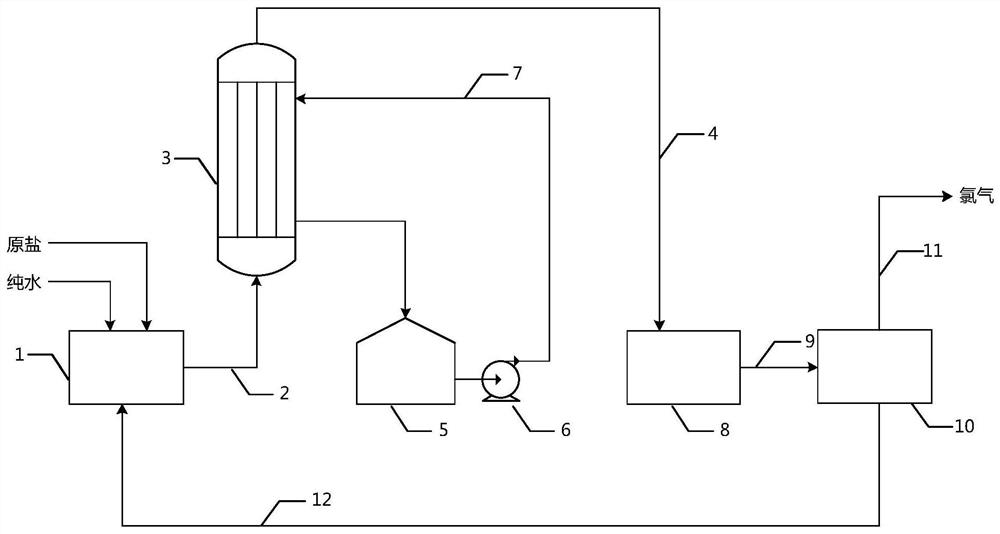

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1 prepares ECTFE-MnO 2 Composite Modified Hollow Fiber Gas Membrane

[0084] Add 1t of ECTFE to 5t of polyethylene glycol and mix evenly, then add 0.33t of DEG and 0.25t of perfluorooctyltrichlorosilane at the same time, and stir slowly in a water bath at 50°C (stirring speed 20r / min) for 60min to obtain a clear Transparent casting solution. Under nitrogen extrusion at an external pressure of 2 barg, the casting liquid was passed through a spinning device to obtain a hollow fiber membrane, soaked in pure water for 36 hours, and then vacuum-dried at 60°C for 4 hours.

[0085] At 25°C, prepare 2t of 2.0% NH 4 HCO 3 and 3.0% MnSO 4 solution, to MnSO 4 Add 33.3 kg of perfluorooctyltrichlorosilane into the solution and fully stir to dissolve to prepare a mixed solution. NH under ultrasonic radiation environment 4 HCO 3 The solution was slowly added dropwise to the above mixed solution, the dropping time was 60min, the ultrasonic pulse frequency was 15kHz, ...

Embodiment 2

[0088] Add 1t of ECTFE to 7t of polyethylene glycol and mix evenly, add 0.5t of DEG and 0.33t of perfluorooctyltrichlorosilane at the same time, stir slowly in a water bath at 50°C (stirring speed 20r / min) for 90min, and obtain a clear and transparent casting solution. Under the extrusion of nitrogen at an external pressure of 3 barg, the casting solution was passed through a spinning device to obtain a hollow fiber membrane, soaked in pure water for 48 hours, and then vacuum-dried at 80°C for 8 hours.

[0089] At 25°C, prepare 2t of 2.0% NH 4 HCO 3 and 3.0% MnSO 4 solution, to MnSO 4 Add 50 kg of perfluorooctyltrichlorosilane into the solution and fully stir to dissolve to prepare a mixed solution. NH under ultrasonic radiation environment 4 HCO 3 The solution was slowly added dropwise to the above mixed solution, the dropping time was 90min, the ultrasonic pulse frequency was 20kHz, and the pulse width was 300ms. Crystallize at 400°C, 500°C, and 600°C for 5 hours to p...

Embodiment 3

[0092] Add 1t of ECTFE to 6t of polyethylene glycol and mix evenly, add 0.4t of DEG and 0.3t of perfluorooctyltrichlorosilane at the same time, stir slowly in a water bath at 50°C (stirring speed 20r / min) for 75min, and obtain a clear and transparent casting solution. Under nitrogen extrusion at an external pressure of 2.5 barg, the casting solution was passed through a spinning device to obtain a hollow fiber membrane, soaked in pure water for 42 hours, and then vacuum-dried at 70°C for 6 hours.

[0093] At 25°C, prepare 2t of 2.0% NH 4 HCO 3 and 3.0% MnSO 4 solution, to MnSO 4 40 kg of perfluorooctyltrichlorosilane was added into the solution and fully stirred to dissolve to prepare a mixed solution. NH under ultrasonic radiation environment 4 HCO 3 The solution was slowly added dropwise to the above mixed solution, the dropping time was 75min, the ultrasonic pulse frequency was 18kHz, and the pulse width was 220ms. After the reaction was complete, the mixed liquid was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com