Method for preparing SiNCB ceramic material

A technology of ceramic materials and silicon sources, which is applied in the field of preparation of ceramic materials, can solve the problems of easy crystallization and instability of SiNCB ceramic materials, achieve excellent oxidation resistance, ceramic production rate and high temperature stability, and yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

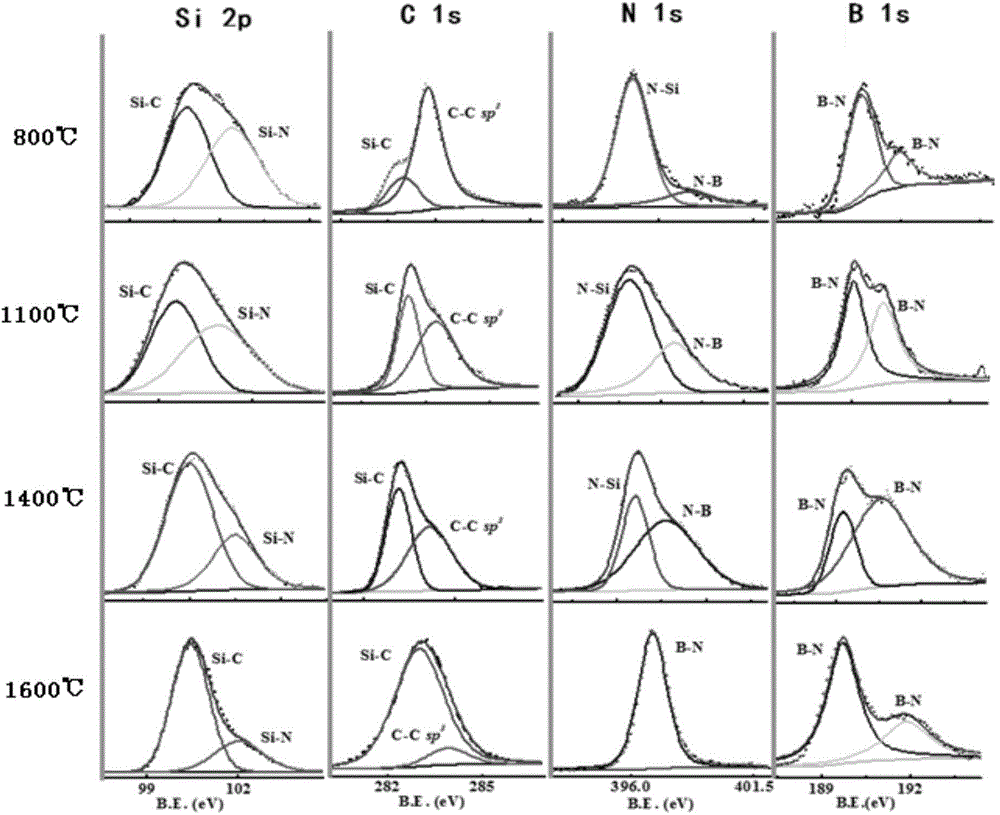

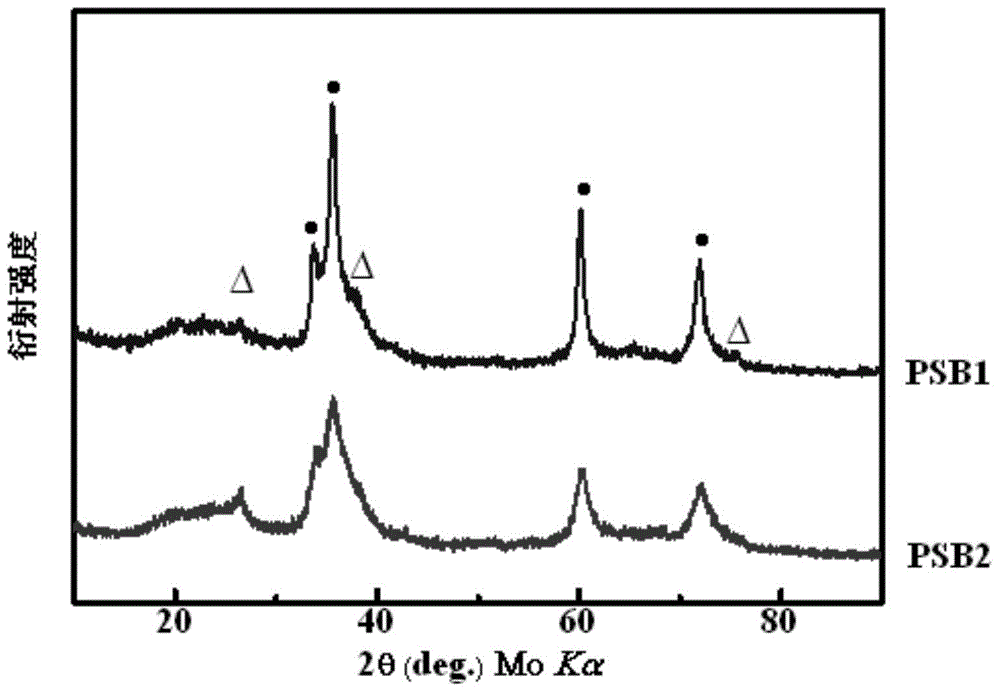

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: the preparation method of the present embodiment SiNCB ceramic material, carry out according to the following steps:

[0014] 1. Put nitrogen source, silicon source, acid-binding agent and solvent into a reactor with inert gas protection, and react for 16 hours at room temperature, wherein the molar ratio of nitrogen source and silicon source is 1-2:1, silicon source and The molar ratio of the solvent is 1:1-5, and the molar ratio of the silicon source and the acid-binding agent is 2:1;

[0015] 2. Vacuum filter the reaction product of step 1, mix the filtered liquid with 2mol / L borane tetrahydrofuran at a molar ratio of 1:1, put it into a reactor protected by an inert gas, and set it at 0°C Under the condition of reaction 12h;

[0016] 3. Then add 1 mol / L boron trichloride n-hexane solution to the reactor, the molar ratio of the product in the reactor to the boron trichloride n-hexane solution is 1:3, after reacting at 0°C for 12 hours warmin...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment is different from Embodiment 1 in that the nitrogen source in step 1 is hexamethyldisilazane or ethylenediamine. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the silicon source in step one is methyl vinyl silazane methyl hydrogen silazane copolymer, methyl vinyl dichlorosilane A mixture of one or two in any ratio. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com