Genetically engineered bacterium and applications thereof

A technology of genetically engineered bacteria and genes, applied in genetic engineering, application, plant genetic improvement, etc., can solve the problems of low endogenous expression of soluble polysaccharide monooxygenase and secretion capacity of soluble polysaccharide monooxygenase, etc. Achieve the effect of increasing production, increasing degradation speed and degree, and high glucose release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This example is used to illustrate the method for constructing genetically engineered bacteria provided by the present invention.

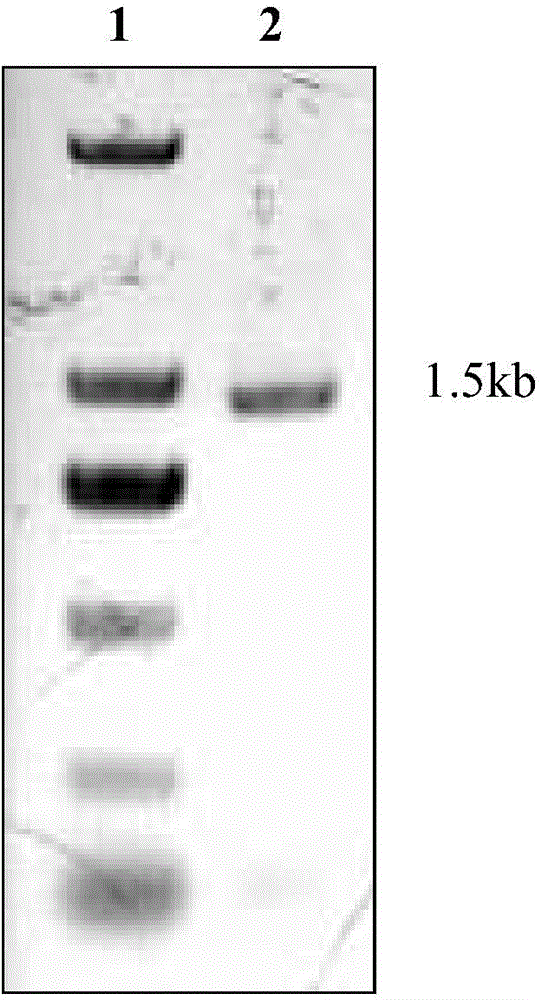

[0077] Take Phanerochaetechrysosporium hyphae, absorb water on filter paper, grind with liquid nitrogen, add GenStar's RNA extraction reagent Trizol by volume: mass ratio 1:1, shake for 5 minutes with a shaker, and stand at room temperature for 1 minute; Volume: mass ratio 0.2:1 add chloroform, shake for 15s, let stand for 2min, centrifuge at 4℃, 12000rpm for 15min; aspirate the supernatant, add isopropanol according to volume ratio 1:1, precipitate at -20℃ for 30min; at 4℃, Centrifuge at 12000rpm for 15min, discard the supernatant, wash the pellet with 1ml of 75% ethanol, centrifuge at 4℃, 7500rpm for 5min, discard the supernatant, and dry for 10min; add DEPC water to dissolve to obtain total RNA, use reverse transcription kit to remove the total RNA Reverse transcription into cDNA; use the sequence shown in SEQ ID NO: 3 as the upstream prime...

Embodiment 2

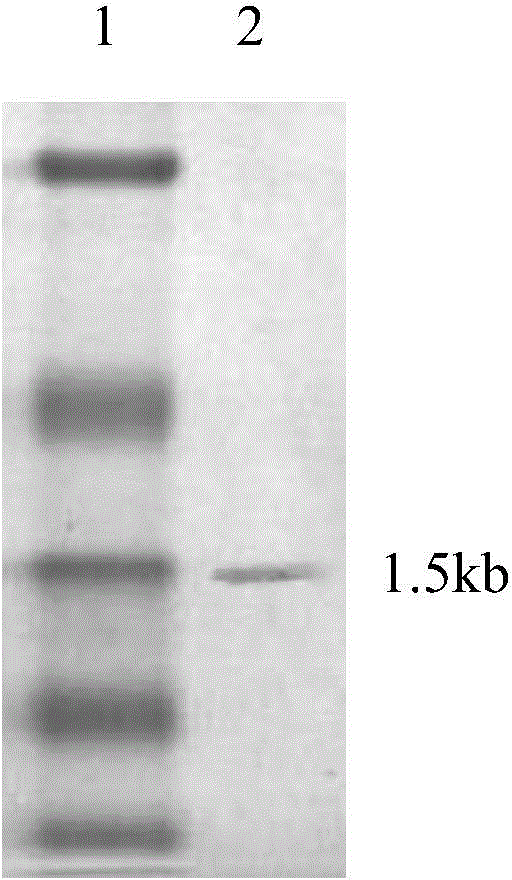

[0085] This example is used to illustrate the secretion ability of soluble polysaccharide monooxygenase with CBM module obtained by the method for constructing genetically engineered bacteria provided by the present invention.

[0086] The genetically engineered single colony of Pichia pastoris obtained in Example 1 was selected and cultured in BMGY medium at 28°C and 150 rpm to OD 600 =2-6; collect the bacteria, resuspend the bacteria with BMMY to make OD 600 =1.0, add 100% methanol to the culture medium to a final concentration of 1.0%; add methanol every 24 hours to a final concentration of 1.0%, and end the induction after 24 hours. SDS-PAGE electrophoresis detects the fermentation broth supernatant after 72 hours of induction.

[0087] BMGY medium formula: 10g / L yeast powder, 20g / L peptone, 100mM pH 6.0 potassium phosphate, 13.4g / L YNB, 4×10 6 g / L biotin, l0g / L glycerol.

[0088] BMMY medium formula: 10g / L yeast powder, 20g / L peptone, 100mM pH 6.0 potassium phosphate, 13.4g / L YNB...

Embodiment 3

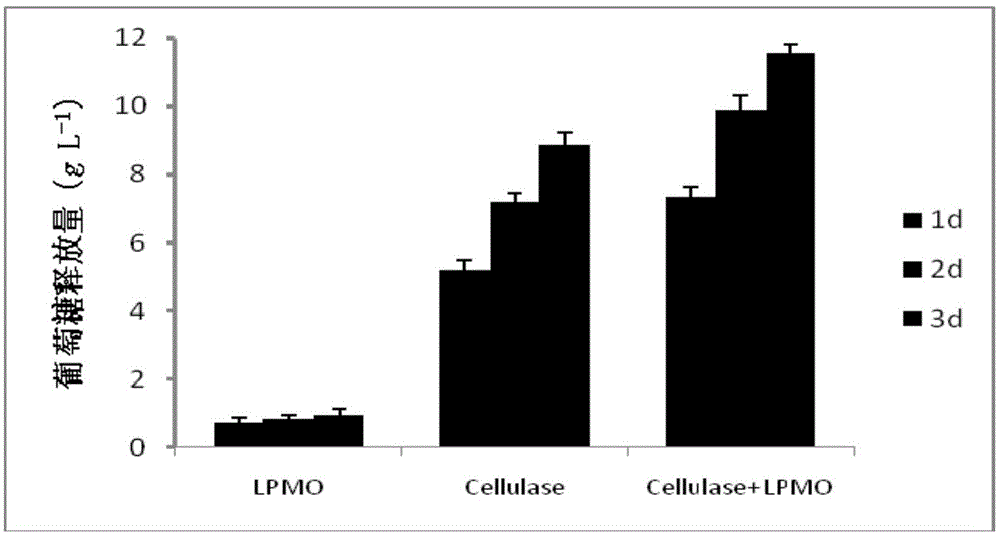

[0091] This example is used to illustrate the application of the genetically engineered bacteria provided by the present invention in the degradation of cellulose materials.

[0092] Add 2g of cellulase and 0.1g of the soluble polysaccharide monooxygenase 10320 obtained in Example 2 to 20g of microcrystalline cellulose as a substrate, react at 50°C for 72 hours, and release glucose up to 11.5g / L. Compared with a single addition of cellulase (Cellulase "Onozuka" R-10), the glucose release increased by 30% ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com