Preparation method of long-acting water replacement type hard membrane corrosion inhibitor for aircrafts

A technology of water displacement and corrosion inhibitor, which is applied in the field of preparation of long-acting water displacement type hard coating corrosion inhibitor for aircraft, can solve the problems of corrosion, high humidity, corrosion of structure, system and electrical equipment, etc., and achieve anti-rust performance. Strong, good heat and humidity resistance, good salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

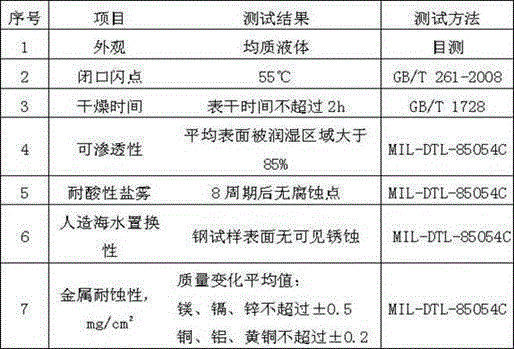

[0039] This case is formulated according to the following components and parts by weight: terpene resin 17, naphtha 14, solvent naphtha D40 25, barium petroleum sulfonate 10, barium 2-nonylnaphthalene sulfonate 8, aminotrimethylene phosphonic acid 6 , Hydroquinone 4, Diisobutyl phthalate 5, Benzotriazole 3, Siben-80 5, Isopropanol 3, Toner balance. Test after the configuration is complete, some technical indicators are as follows:

[0040]

Embodiment 2

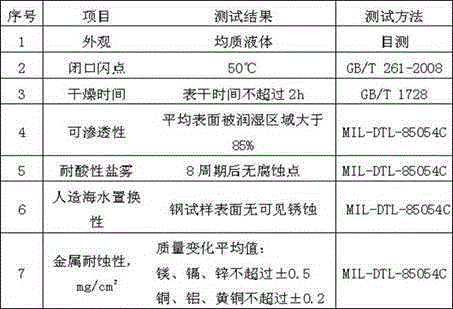

[0042] This case is formulated according to the following components and parts by weight: phenolic resin 20, solvent oil D40 12, solvent oil D60 25, barium petroleum sulfonate 8, zinc naphthenate 7, aminotrimethylene phosphonic acid 6, tert-butyl p- Cresol 3, dicyclohexylamine oleate 4, lanolate 4, Siben-80 5, acetylene alcohol 6, toner balance. Test after the configuration is complete, some technical indicators are as follows:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com