Lithium ion battery electrode based on graphene and preparation method thereof

A lithium-ion battery and graphene technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as high cost, poor heat dissipation performance, safety and rate performance deviation, etc., and achieve high electronic conductivity, lithium-ion The effect of large diffusion coefficient and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh graphene and NMP according to the weight ratio of 1:30, and ultrasonically disperse at 30°C for 6 hours before use;

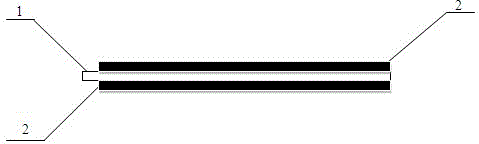

[0022] (2) Weigh the spinel lithium manganate, conductive agent, and pvdf according to the mass ratio of 80:10:10, and the ratio of graphene, acetylene black, and KS-6 in the conductive agent is 1:5:4 [Note: Graphene has been prepared in (1) and ready for use], add 1.5 times the total mass of NMP to prepare the slurry, and spray the graphene mixture prepared in (1) into the electrode slurry during the slurry preparation process, and then The evenly mixed battery slurry was scraped onto aluminum foil ( figure 1 Middle 1) Bake at 120°C for 4 hours to obtain a 50 μm thick electrode material coating ( figure 1 Middle 2) Lithium-ion battery electrodes are made.

Embodiment 2

[0026] (1) Weigh graphene and NMP according to the weight ratio of 1:100, and ultrasonically disperse at 40°C for 3 hours before use;

[0027] (2) Weigh lithium iron phosphate, conductive agent, and pvdf according to the mass ratio of 80:10:10, and the proportion of graphene, acetylene black, and SO in the conductive agent is 1:5:4 [Note: graphene has been (1 ) to be ready for use], add 1 times the total mass of NMP to prepare the slurry, spray the graphene mixture prepared in (1) into the electrode slurry during the slurry preparation process, and then mix the uniformly mixed battery slurry Feed roller coated onto aluminum foil ( figure 1 Middle 1) Bake at 110°C for 7 hours to obtain a 100 μm thick electrode material coating ( figure 1 Middle 2) Lithium-ion battery electrodes are made.

Embodiment 3

[0031] (1) Weigh graphene and NMP according to the weight ratio of 1:500, and ultrasonically disperse at 30°C for 5 hours before use;

[0032] (2) Weigh nickel-cobalt lithium manganese oxide, conductive agent, and pvdf according to the mass ratio of 80:10:10, and the proportion of graphene, acetylene black, and KS-6 in the conductive agent is 2:5:3 [Note: graphite Graphene has been prepared in (1) for use], add 1.3 times the total mass of NMP to prepare the slurry, spray the graphene mixture prepared in (1) into the electrode slurry during the slurry preparation process, and then uniformly The mixed battery slurry is sprayed onto aluminum foil ( figure 1 Middle 1) bake at 120°C for 5 hours to obtain a 90 μm thick electrode material coating ( figure 1 Middle 2) Lithium-ion battery electrodes are made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com