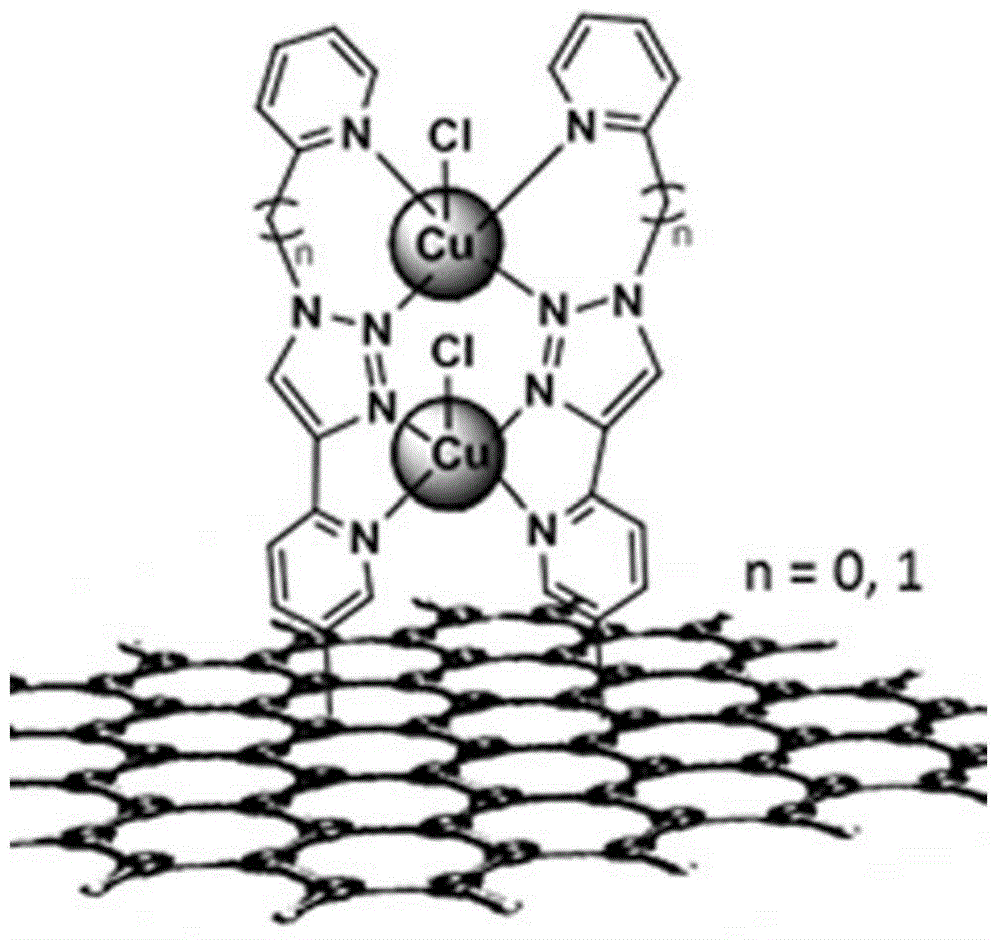

Preparation of carbon material covalent loading bionic multi-core copper-oxygen reduction electrocatalyst

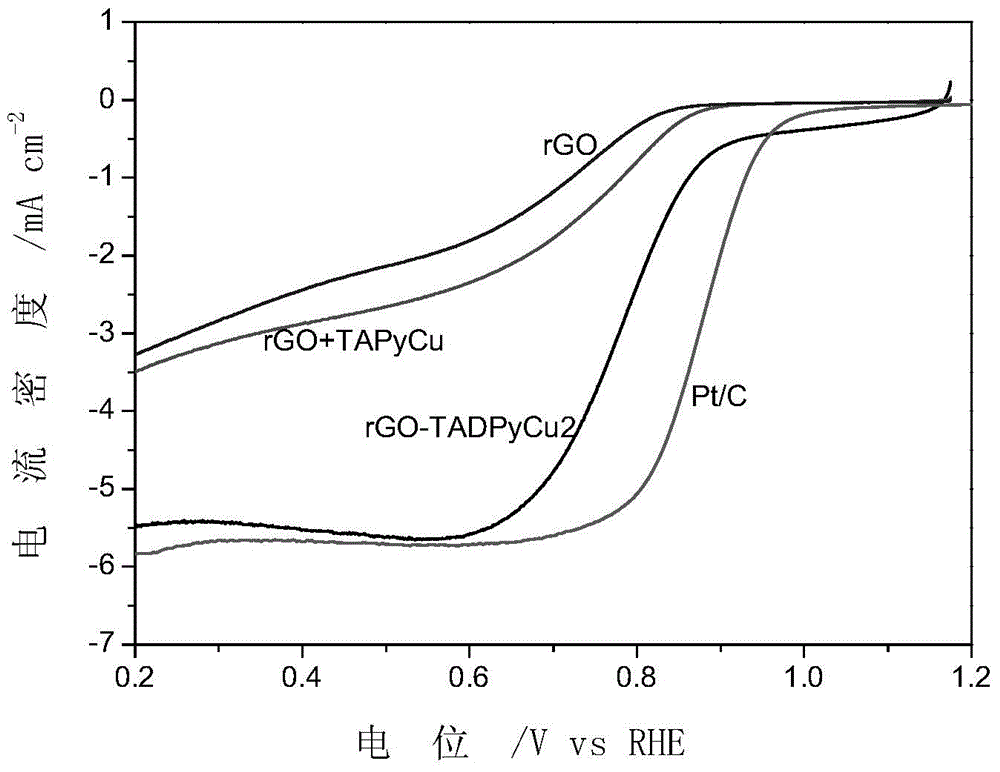

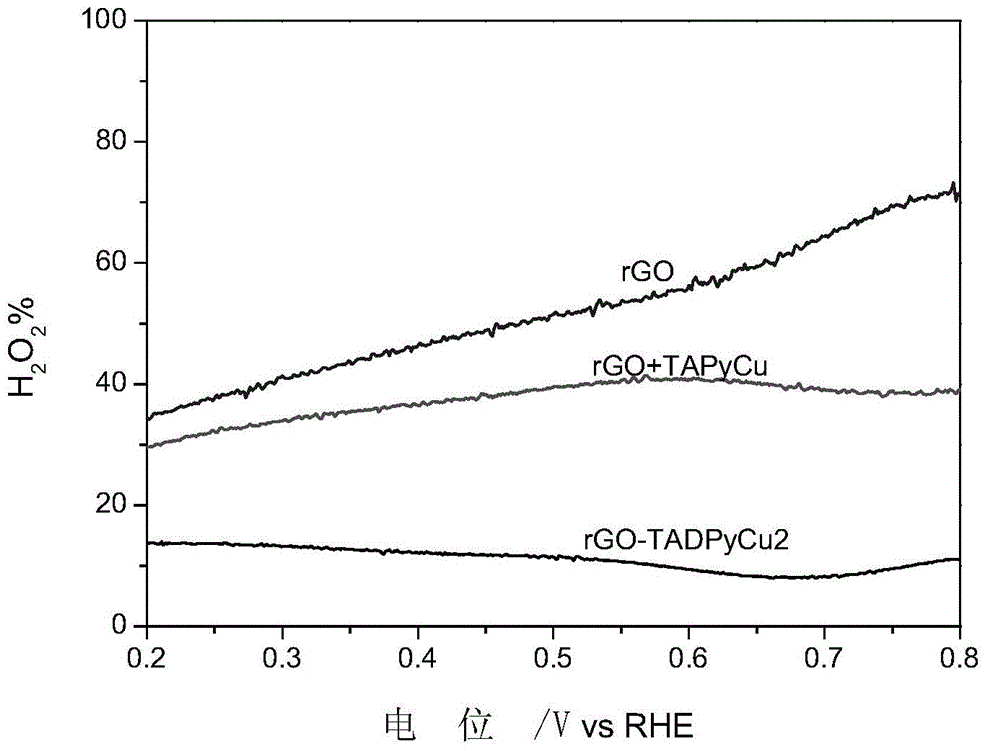

An electrocatalyst and polynuclear copper technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as poor stability, far-reaching goals, and inability to control catalyst reactivity, so as to increase oxygen flux, improve activity, and improve catalyst structure. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Functional modification of triazole groups on the surface of graphene oxide

[0040] Dissolve purified graphene oxide (SP-1graphite, purchased from Bay Carbon Corporation) and triisopropylsilylpyridine in acetonitrile and disperse uniformly by ultrasonic, add a certain amount of isoamyl nitrite solution, and heat to 80°C , Reacted for 24h under the protection of nitrogen. The resulting filter cake was filtered, washed with DMF until the filtrate was colorless, and then dispersed in DMF.

[0041] Take a certain amount of the dispersion obtained in the above steps, add tetrabutylammonium fluoride under an ice-water bath, and react for 4 hours at room temperature under a nitrogen atmosphere. Then, a certain amount of copper sulfate pentahydrate, sodium ascorbate and 2-azidopyridine were respectively added therein, and reacted at 50° C. for 36 h under a nitrogen atmosphere. Filter the obtained filter cake, wash with DMF, 50mmol / L EDTA aqueous solution, and ultra...

Embodiment 2

[0042] Example 2 Coordination loading of copper salt on the surface of reduced graphene oxide

[0043] Mix 10.0mg modified reduced graphene oxide with 20.0mg CuCl 2 2H 2 O was dispersed in 20.0 mL of acetonitrile and stirred at room temperature for 24 h. The complex was filtered, washed three times with a small amount of acetonitrile and water, dried in vacuum for 4 h, and the target compound obtained in the above steps was stored in a dark place under a nitrogen atmosphere.

Embodiment 3

[0044] The preparation of embodiment 3rGO+TAPyCu

[0045] Preparation of TAPyCu

[0046] Dissolve a certain amount of 2-azidopyridine and 2-ethynylpyridine in DMF, add a certain amount of copper sulfate pentahydrate and sodium ascorbate, heat to 80°C, and react for 36 hours under nitrogen protection. After treatment, wash with a large amount of water to remove DMF, extract with dichloromethane to obtain an organic phase, and obtain the target product TAPy by column chromatography. A certain amount of TAPy and CuCl 2 2H 2 O was dispersed in acetonitrile, and after stirring at room temperature for 24 h, the post-treatment was washed with acetonitrile for several times until the filtrate was colorless, and the target product TAPyCu was obtained.

[0047] Preparation of rGO+TAPyCu

[0048] Take a certain amount of TAPyCu and rGO and disperse them in acetonitrile, stir at room temperature for 16 hours, filter and dry to obtain the target product rGO+TAPyCu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com