All-solid polymer electrolyte with surface chemically grafted inorganic particles and preparation method

An all-solid polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrochemical generators, etc., can solve the problems of low conductivity of solid polymer electrolytes, and achieve excellent battery performance and excellent conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Dissolve 1.32ml of ethyl silicate in 10ml of ethanol to make solution A, dissolve 0.42ml of deionized water in 10ml of ethanol to make solution B, control the pH value at 3-4.5, drop B solution into A In the solution, after the dropwise addition, hydrolyze at 60°C for 2 hours, then add 0.1 g of silane coupling agent to it, and react at 80°C for 2 hours under a nitrogen atmosphere to obtain a sol particle reaction solution;

[0019] The second step: in the sol particle reaction solution prepared in the first step, add monomer polyoxyethylene methyl methacrylate, polydimethylsiloxane and initiator azobisisobutyronitrile with 30 oxyethylene segments, Wherein the molar ratio of polyoxyethylene methyl methacrylate to polydimethylsiloxane monomer is 1:1.5, and reacted at 90°C for 4 hours to obtain an amorphous nanocomposite reaction liquid; The total reaction mass concentration of methyl acrylate and polydimethylsiloxane is 0.2g / mL, and the mass concentration of initi...

Embodiment 2

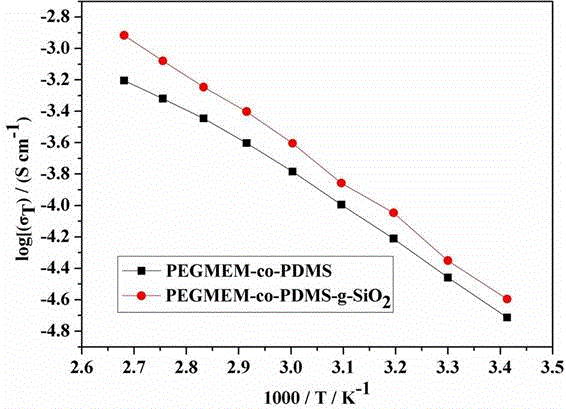

[0023] Example 1 prepares an all-solid polymer electrolyte for a solid lithium-ion battery. The polymer is composed of monomer polyoxyethylene methyl methacrylate, polydimethylsiloxane and SiO 2 Polymerized composites doped with lithium trifluoromethanesulfonate (EO / Li=20 / 1), the number of oxyethylene segments of polyoxyethylene methyl methacrylate is 30, SiO 2 The content is 2% by mass fraction, and its electrical conductivity is compared with that of the ungrafted polymer electrolyte as figure 1 shown. From figure 1 It can be seen in the grafted SiO 2 Finally, the electrical conductivity of the solid-state polymer nanocrystalline particles obtained in Example 1 all improved at different temperatures, and at a high temperature of 100 degrees, the electrical conductivity was as high as 10 -3 , reaching the order of magnitude required for practical applications.

Embodiment 3

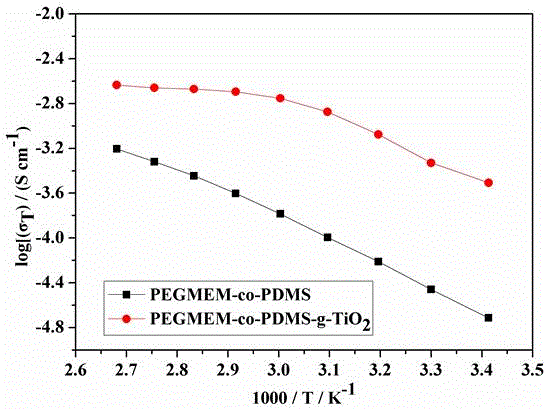

[0025] Step 1: Dissolve 2ml tetraethyl titanate in 10ml ethanol to make solution A, dissolve 0.53ml deionized water in 10ml ethanol to make solution B, control the pH value at 3-4.5, and drop solution B into A In the solution, after the dropwise addition, hydrolyze at 60°C for 2 hours, then add 0.1 g of silane coupling agent to it, and react at 80°C for 2 hours under a nitrogen atmosphere to obtain a sol particle reaction solution;

[0026] The second step: in the sol particle reaction solution prepared in the first step, add monomer polyoxyethylene methyl methacrylate, polydimethylsiloxane and initiator azobisisobutyronitrile with 30 oxyethylene segments, Wherein the molar ratio of polyoxyethylene methyl methacrylate to polydimethylsiloxane monomer is 1:1.5, react at 90°C for 4 hours to obtain an amorphous nano-composite reaction liquid; The total reaction mass concentration of methyl acrylate and polydimethylsiloxane is 0.2g / mL, and the mass concentration of initiator azobis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com