Preparation method of nano-TiO2-modified composite hydrogel

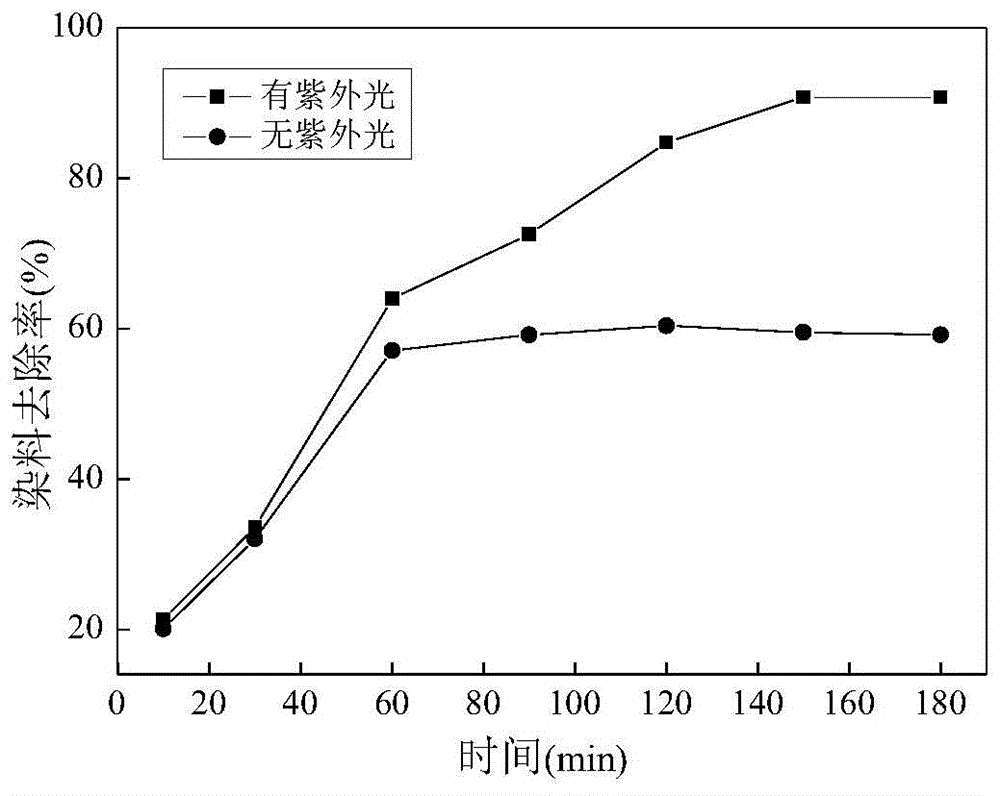

A composite hydrogel and nanotechnology, applied in chemical instruments and methods, alkali metal compounds, adsorbed water/sewage treatment, etc., can solve the problems of low adsorption efficiency and poor adsorption effect, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of nanometer TiO of the present invention 2 The preparation method of modified composite hydrogel specifically comprises the following steps:

[0026] Step 1: dissolving chitosan in an acetic acid solution with a mass concentration of 1% to 2%, the mass ratio of chitosan to acetic acid solution being 1:50 to 100, and magnetic stirring for 12 to 24 hours to obtain a chitosan solution;

[0027] Step 2: N’N-methylenebisacrylamide (BIS), nano-TiO 2 , N-isopropylacrylamide (NIPAAm) into the three-necked flask, N'N-methylenebisacrylamide (BIS), nano-TiO 2 , The mass ratio of N-isopropylacrylamide (NIPAAm) to chitosan is 2.5-3.5:0.23-0.36:2.3-3.6:1, nano-TiO 2 Anatase type is preferred, the particle size is preferably 10-30nm, mixed with the chitosan solution obtained in step 1, and ultrasonically dispersed for 10-20 minutes to obtain a mixed solution;

[0028] Step 3: Add initiator and tetramethylethylenediamine to the mixed solution obtained in step 2 under the pro...

Embodiment 1

[0032] Step 1: dissolving 1g of chitosan in 66g of acetic acid solution with a mass concentration of 1%, and magnetic stirring for 24 hours to obtain a chitosan solution;

[0033] Step 2: 2.8g N'N-methylenebisacrylamide (BIS), 0.3g nano-TiO with anatase average particle size of 20nm 2 , 3g N-isopropylacrylamide (NIPAAm) was added in the three-necked flask, and mixed with the chitosan solution obtained in step 1, and ultrasonically dispersed for 10min to obtain a mixed solution;

[0034] Step 3: Add 0.08 g of ammonium persulfate and 0.03 g of tetramethylethylenediamine to the mixed solution obtained in step 2 at room temperature and under the protection of nitrogen, stir for 1 h, and then freeze for 24 h to obtain nano-TiO 2 Modified composite hydrogel crude product;

[0035] Step 4: the nano-TiO obtained in step 3 2 The crude product of the modified composite hydrogel was soaked in deionized water for 24 hours, and the water was changed once every 4 hours. 2 Modified compos...

Embodiment 2

[0037] Step 1: dissolving 1g of chitosan in 50g of acetic acid solution with a mass concentration of 2%, and magnetic stirring for 12 hours to obtain a chitosan solution;

[0038] Step 2: 2.5g N'N-methylenebisacrylamide (BIS), 0.36g nano-TiO with anatase average particle size of 10nm 2, 2.3g N-isopropylacrylamide (NIPAAm) was added in a three-necked flask, and mixed with the chitosan solution obtained in step 1, and ultrasonically dispersed for 15min to obtain a mixed solution;

[0039] Step 3: At room temperature and under the protection of nitrogen, add 0.12 g potassium persulfate and 0.05 g tetramethylethylenediamine to the mixed solution obtained in step 2, stir and react for 0.5 h, then freeze and react for 18 h to obtain nano-TiO 2 Modified composite hydrogel crude product;

[0040] Step 4: the nano-TiO obtained in step 3 2 The crude product of the modified composite hydrogel was soaked in deionized water for 24 hours, and the water was changed once every 3 hours. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com