Chromium-polluted soil restoration leaching agent and chromium-polluted soil restoration method

A technology of chromium-contaminated soil and eluent, which is applied in the field of eluents for remediating chromium-contaminated soil, can solve the problems of low pH value of leaching solution, high price, increased elution repair cost, etc., and achieves high removal efficiency, good The effect of repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

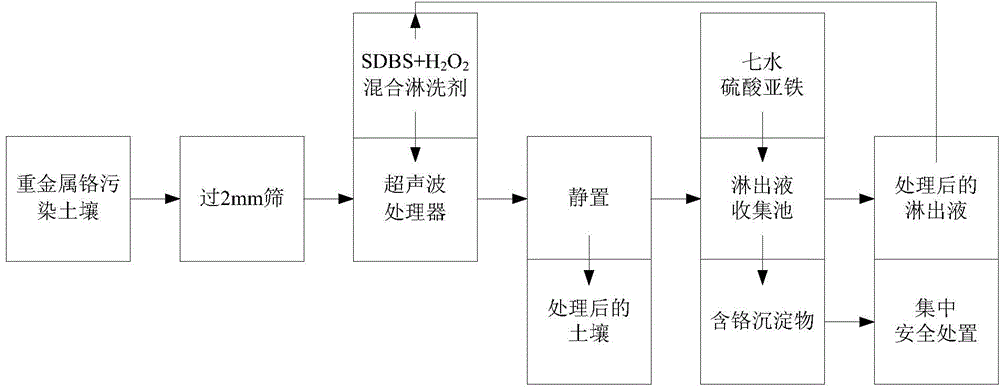

Image

Examples

Embodiment 1

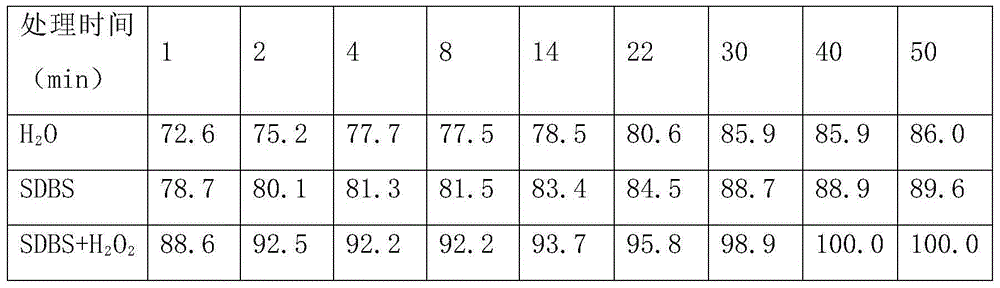

[0023] Accurately weighed 50.00g of contaminated clay from an electroplating factory in Shiyan City, Hubei Province that was passed through a 2mm sieve. The concentration of heavy metal chromium in the soil was 4346.82mg / kg, of which hexavalent chromium accounted for 94.8%. 2 O, 3.48g / LSDBS solution, containing 3.48g / L SDBS and 24g / L H 2 o 2 The mixed solution was used as eluting agent, processed in an ultrasonic processor with a power of 720W and a frequency of 20kHZ, and 5ml of mud was taken at 1, 2, 4, 8, 14, 22, 30, 40, and 50min, and centrifuged at 3000×g After 20 minutes, pass through a 0.45 μm filter membrane, and measure the content of heavy metal chromium in the filtrate. Three parallels were performed for each treatment, and the results were averaged.

[0024] The removal efficiency (unit: %) of three kinds of leaching agents to total chromium in soil under the different treatment time of table 1

[0025]

Embodiment 2

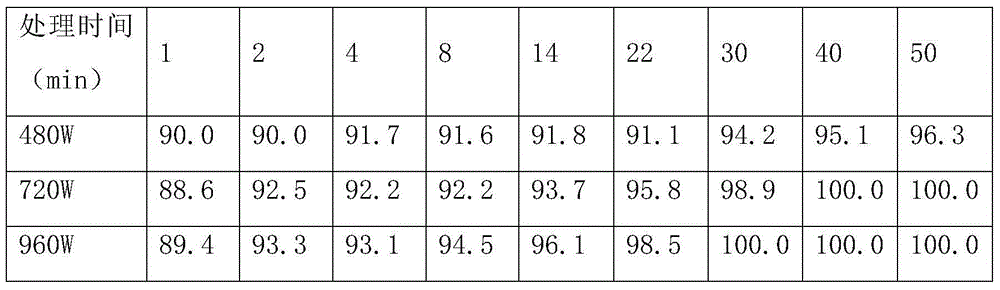

[0027] Accurately weigh 50.00g of the contaminated clay left over from an electroplating factory in Shiyan City, Hubei Province through a 2mm sieve. The concentration of heavy metal chromium in the soil is 4346.82mg / kg, of which hexavalent chromium accounts for 94.8%. According to the solid-liquid ratio of 1:10, 3.48 g / L SDBS and 24g / L H 2 o 2 The mixed solution was used as eluting agent, treated in ultrasonic processor with power of 480W, 720W, 960W and frequency of 20kHZ respectively, and 5ml mud was taken at 1, 2, 4, 8, 14, 22, 30, 40, 50min respectively, Centrifuge at 3000×g for 20 minutes, pass through a 0.45 μm filter membrane, and measure the content of heavy metal chromium in the filtrate. Three parallels were performed for each treatment, and the results were averaged.

[0028] The removal efficiency (unit: %) of total chromium in soil under table 2 different treatment time and power

[0029]

Embodiment 3

[0031] Take 20ml and process it according to the above method to obtain leachate in a 50ml plastic centrifuge tube, the concentration of total chromium in the leachate is 430.0mg / L, add 0.06, 0.08, 0.10, 0.12, 0.16, 0.2g sulfuric acid heptahydrate respectively For ferrous iron, at room temperature and 150rpm, oscillate in a water bath constant temperature oscillator for 20min, centrifuge at 3000×g for 20min, pass through a 0.45μm filter membrane, and measure the content of heavy metal chromium in the filtrate. Three parallels were performed for each treatment, and the results were averaged.

[0032] Table 3 The removal rate of total chromium in the leachate under different ferrous sulfate heptahydrate additions

[0033] Amount of ferrous sulfate heptahydrate added (g)

[0034] As can be seen from the above three groups of embodiments, the use of the leaching agent of the present invention in combination with ultrasonic strengthening treatment has a good repair effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com