Polyaniline-carbon layer-titanium nitride nanowire array composite material and preparation method and application thereof

A titanium nitride nanometer and composite material technology, which is applied in nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing, etc., can solve instability and other problems, and achieve the effect of wide industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

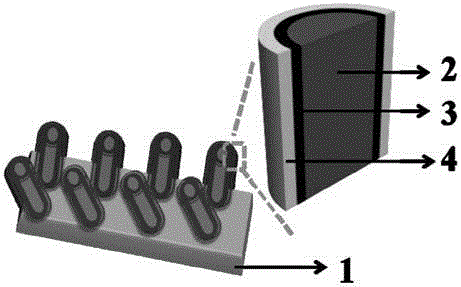

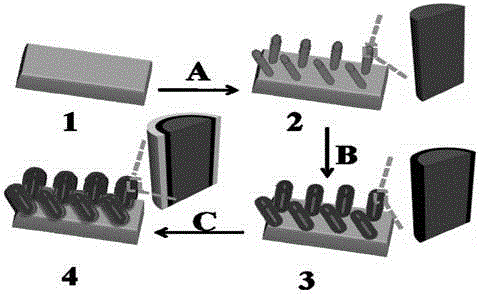

[0032] The schematic diagram of the preparation process of the polyaniline-carbon layer-titanium nitride nanowire array composite material is shown in the appendix of the specification. figure 2. First, based on the seed-assisted hydrothermal reaction method and high-temperature nitriding reaction process (A), a titanium nitride nanowire array was prepared on the surface of the carbon substrate (1): the carbon substrate material was soaked in the impregnated seed solution, and the A seed layer is formed on the surface of the carbon base material. After calcination, it is put into a sealed hydrothermal reaction kettle, and the mixed solution of hydrochloric acid, water and titanium-based precursor is used as the reaction liquid for hydrothermal reaction. After the end, it is nitrided at high temperature under an ammonia atmosphere. reaction to obtain a titanium nitride nanowire array (2) that is ordered on the surface of the carbon substrate; secondly, based on the hydrotherma...

Embodiment 2

[0034] Preparation of polyaniline-carbon layer-titanium nitride nanowire array composites, see figure 2 ,Specific steps are as follows:

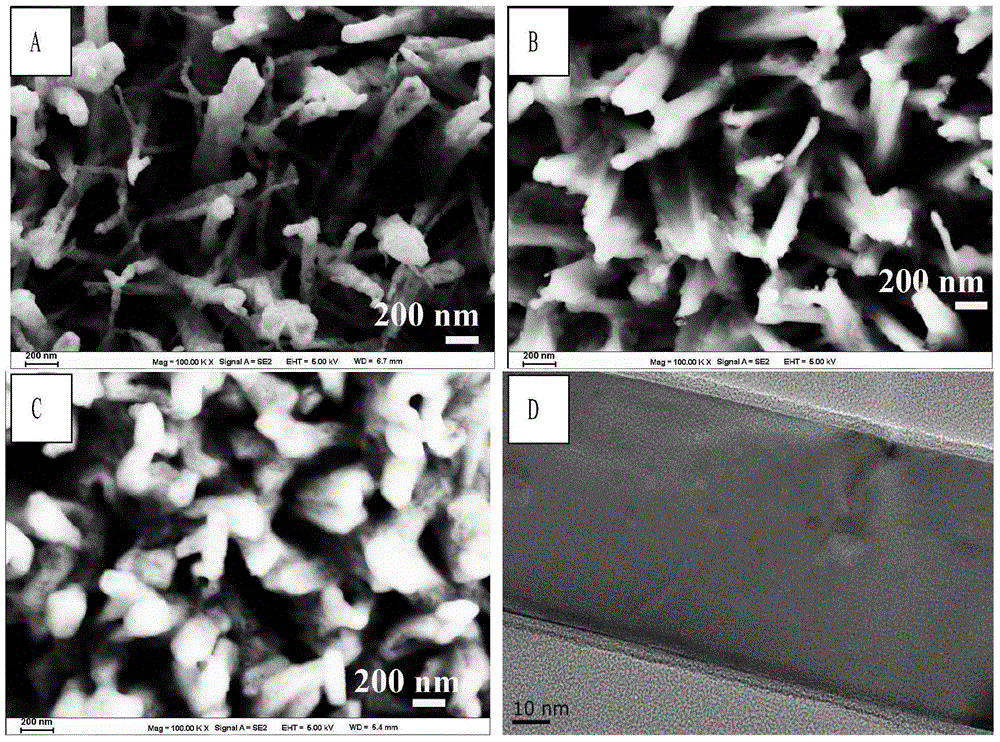

[0035] (1) Titanium nitride nanowire arrays were prepared by seed-assisted hydrothermal reaction method and nitriding treatment method: the carbon fiber cloth substrate was cleaned with acetone, ethanol and deionized water in sequence; the dried carbon fiber cloth was placed in a solution containing 0.3mol / L titanium tetrachloride ethanol solution, fully soaked under stirring, took out and dried, put it into the hollow atmosphere of the tube furnace and calcined at 400°C for 10min; then put the calcined sample into a 100mL hydrothermal reaction kettle, added A mixed reaction solution containing 30mL of 37% concentrated hydrochloric acid, 30mL of water and 0.9mL of tetrabutyl titanate, the hydrothermal reaction time is 8h at 170°C, after the reaction is completed, the product is taken out and placed in a tube furnace under an ammonia atmosp...

Embodiment 3

[0040] The preparation of polyaniline-carbon layer-titanium nitride nanowire array composite material specifically includes the following steps:

[0041] (1) Titanium nitride nanowire arrays were prepared by seed-assisted hydrothermal reaction method and high-temperature nitriding reaction method: the carbon paper substrate was cleaned and dried, and then placed in an ethanol solution containing 0.7mol / L tetrabutyl titanate, After soaking for 20 minutes, take it out and dry it, put it into the hollow atmosphere of the tube furnace and calcinate at 400°C for 10 minutes. Then put the calcined sample into a 50mL hydrothermal reaction kettle, add a mixed reaction solution containing 15mL 37% concentrated hydrochloric acid, 15mL water and 0.5mL tetrabutyl titanate, and the hydrothermal reaction time is 10h at 160°C, and the reaction ends Afterwards, the product was taken out and placed in a tube furnace, and subjected to high-temperature calcination treatment under an ammonia gas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com