Carbon-coating titanium based nano array material and preparation method and application thereof

A nano-array, carbon-coated technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve fast charge and discharge electrochemical storage performance, high capacity electrochemical storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

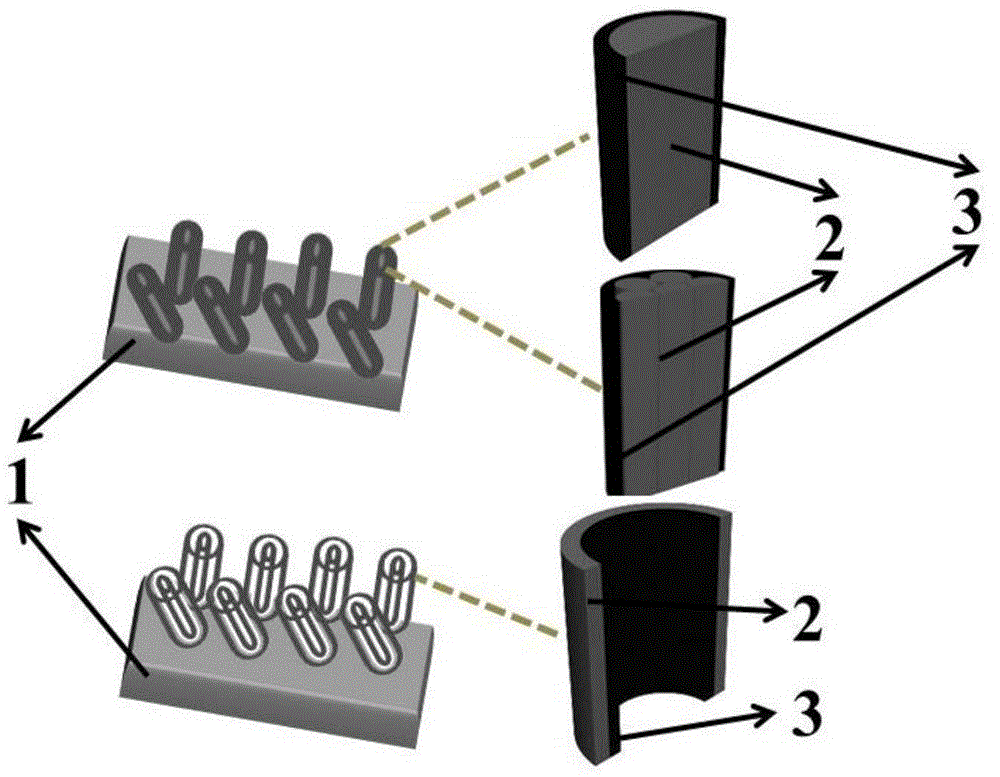

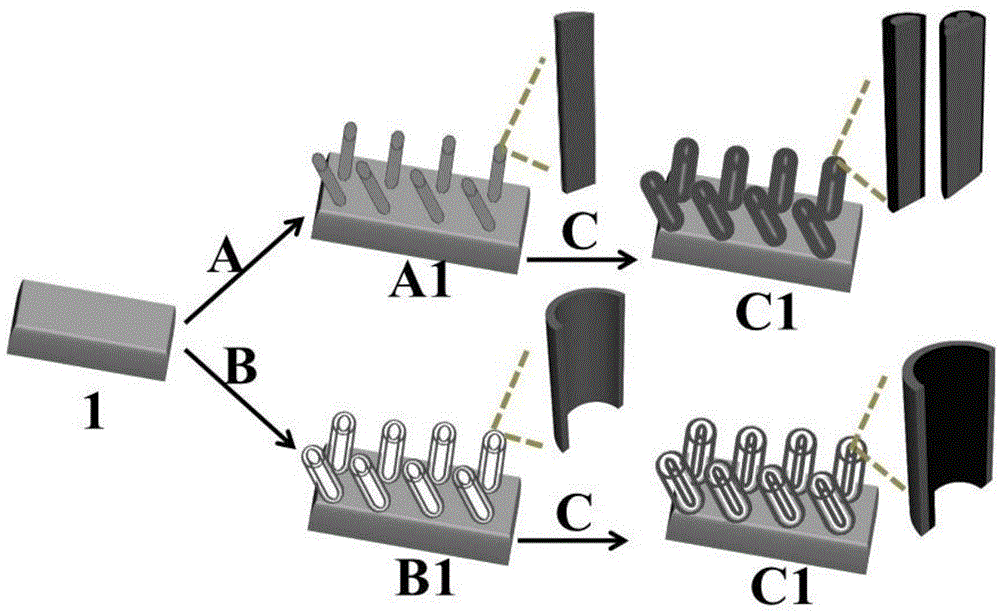

[0032] Preparation of carbon-coated titanium-based nanoarray materials, see figure 2 , including the following steps:

[0033]Based on the seed-assisted hydrothermal reaction method and controlled nitrogen doping reaction or complete nitriding reaction process (A), titanium oxide or nitrogen-doped titanium oxide or titanium nitride nanowires and nanopillars with orderly arrangement on the surface of conductive substrates were prepared Array (A1): soak the conductive substrate in the impregnation seed solution, form a seed layer on the surface of the substrate material by physical adsorption, put it into a sealed hydrothermal reaction kettle after high-temperature calcination, and mix hydrochloric acid, water and titanium-based precursors The liquid is a reaction liquid for hydrothermal reaction, and the material obtained from the reaction is subjected to a controlled nitrogen doping reaction or a complete nitriding reaction in an ammonia atmosphere to obtain titanium oxide, t...

Embodiment 2

[0037] A method for preparing a carbon-coated titanium nitride nanowire array material, the specific steps are as follows:

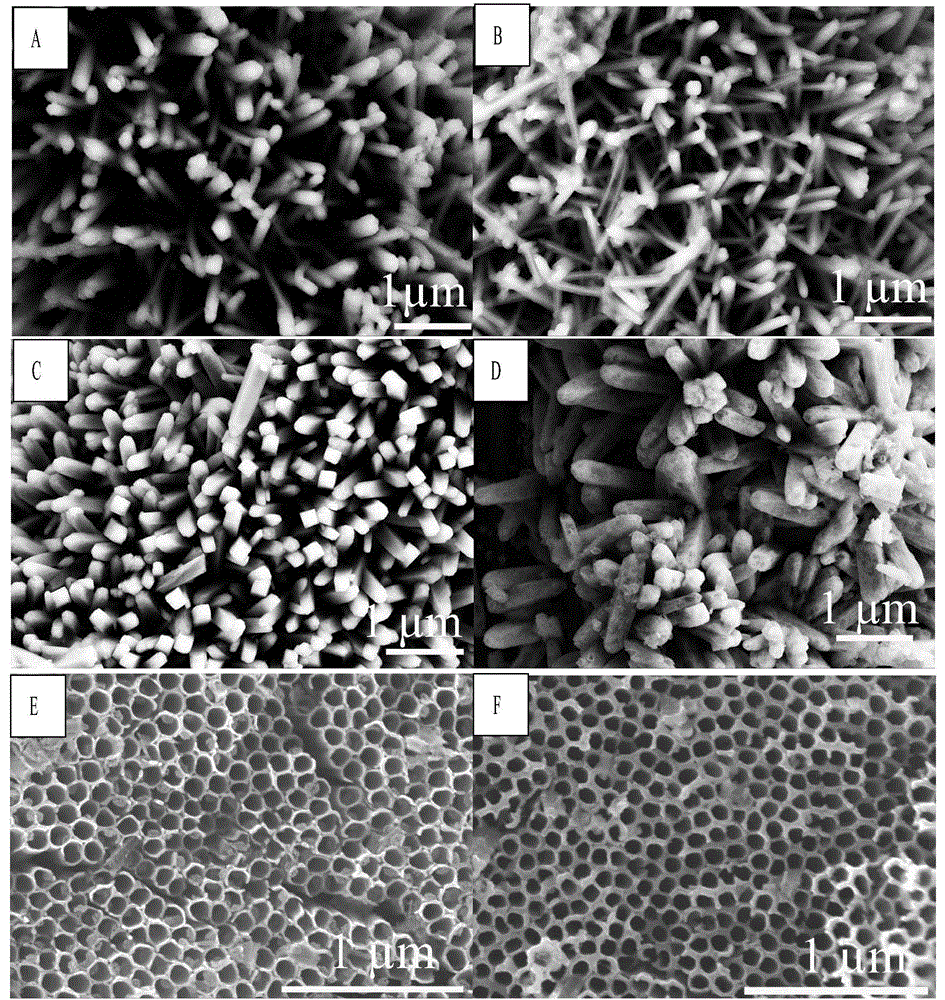

[0038] (1) Titanium oxide nanowire arrays were prepared by seed-assisted hydrothermal reaction method and high-temperature calcination treatment method: the carbon cloth substrate was cleaned with acetone, ethanol and deionized water in sequence. Put the dried carbon cloth into an ethanol solution containing 0.5 mol / L titanium tetrachloride, soak it fully under stirring, take it out and dry it, put it into a tube furnace, and calcinate it at 400°C for 10 minutes under a nitrogen atmosphere; then Put the calcined sample into a 100mL hydrothermal reaction kettle, add a mixed reaction solution containing 30mL 37% concentrated hydrochloric acid, 30mL water and 0.6mL tetrabutyl titanate, and the hydrothermal reaction time is 7h at 180°C. The product was taken out and placed in a tube furnace, and calcined at a high temperature of 450°C for 2 hours under a nit...

Embodiment 3

[0043] A method for preparing a carbon-coated titanium nitride nanocolumn array material, the specific steps are as follows:

[0044] (1) Titanium oxide nanocolumn arrays were prepared by seed-assisted hydrothermal reaction method and high-temperature calcination: the graphite sheet was washed and dried, then put into ethanol solution containing 0.8mol / L tetraisopropyl titanate, soaked for 10min Take it out and dry it, put it into a tube furnace, and calcine it at 400°C for 10 minutes under a nitrogen atmosphere. Then put the calcined sample into a 100mL hydrothermal reaction kettle, add a mixed reaction solution containing 30mL 37% concentrated hydrochloric acid, 30mL water and 1.0mL tetrabutyl titanate, and the hydrothermal reaction time is 20h at 150°C, and the reaction ends Finally, the product was taken out and placed in a tube furnace, and calcined at 450°C for 2 hours under a nitrogen atmosphere, the nitrogen concentration was 99.7%, the nitrogen flow rate was 55mL / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com