Nickel-titanium amorphous alloy grid supporting film for transmission electron microscope

A technology of electron microscopy and amorphous alloy thin film, which is applied in the direction of circuits, discharge tubes, sputtering coating, etc., can solve the problems of charge accumulation and low mechanical strength of the support film, and achieve large-scale mass production, improve mechanical strength, The effect of easy parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

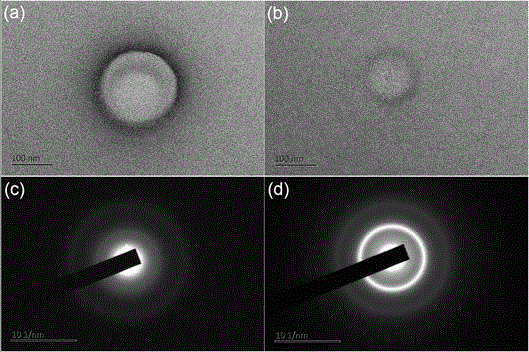

[0029] A nickel-titanium amorphous alloy grid supporting film for a transmission electron microscope, the nickel-titanium amorphous alloy grid supporting film is successively a grid and an amorphous alloy thin film layer from bottom to top, and the amorphous alloy thin film layer contains nickel and titanium elements.

[0030] Further, the content of the nickel element is 40-60 at.%, and the content of the titanium element is 60-40 at.%.

[0031] Further, the thickness of the amorphous alloy film layer is 5-18 nm.

[0032] The preparation method of the nickel-titanium amorphous alloy grid supporting film for the transmission electron microscope comprises the following steps:

[0033] (1) Prepare an organic film as a transition film;

[0034] (2) Floating the organic film into water, spreading the carrier net and filter paper on the organic film successively to obtain the carrier net covered with the organic film;

[0035] (3) Using magnetron sputtering or thermal evaporatio...

Embodiment 2

[0042] This embodiment is a preferred solution on the basis of Example 1, wherein the organic film is selected from Fanghua film, and the preparation method of the nickel-titanium amorphous alloy gold-carrying grid support film includes the following steps:

[0043] (1) Prepare a 0.5% Fanghua powder solution, insert a clean glass slide into the Fanghua powder solution, let it stand for 10 s, remove the slide from the solution, place it in a petri dish, dry it, and scratch it with a blade. Cut the surrounding area of the film on the glass slide, insert the glass slide into clean distilled water obliquely, the Fanghua film will fall off from the glass slide and float on the surface of the distilled water.

[0044] (2) Ultrasonic clean the carrier grid without support membrane with acetone for 5 minutes, then wash it twice with clean distilled water, remove it, dry it, spread it on the Fanghua membrane one by one, cut the filter paper with the same size as the membrane area, La...

Embodiment 3

[0050] The present embodiment is a preferred scheme on the basis of Example 1, wherein the organic film is selected from collodion film, and the preparation method of the nickel-titanium amorphous alloy gold-carrying mesh support film comprises the following steps:

[0051] (1) make solvent with amyl acetate, prepare 2% collodion solution;

[0052] (2) Use a glass dropper to drop a drop of collodion solution on the surface of clean distilled water. The collodion solution quickly spreads to form a film on the water surface. Use a clean lens tissue to wipe off the collodion film on the water surface to clean the water surface. ;

[0053] (3) Drop another drop of collodion solution on the surface of distilled water, and the collodion solution spreads rapidly on the water surface to form a film;

[0054] (4) Soak the grid in clean acetone for 5 min to clean the organic matter on the surface of the grid, and then rinse it with clean distilled water for 3 times to obtain the cleane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com