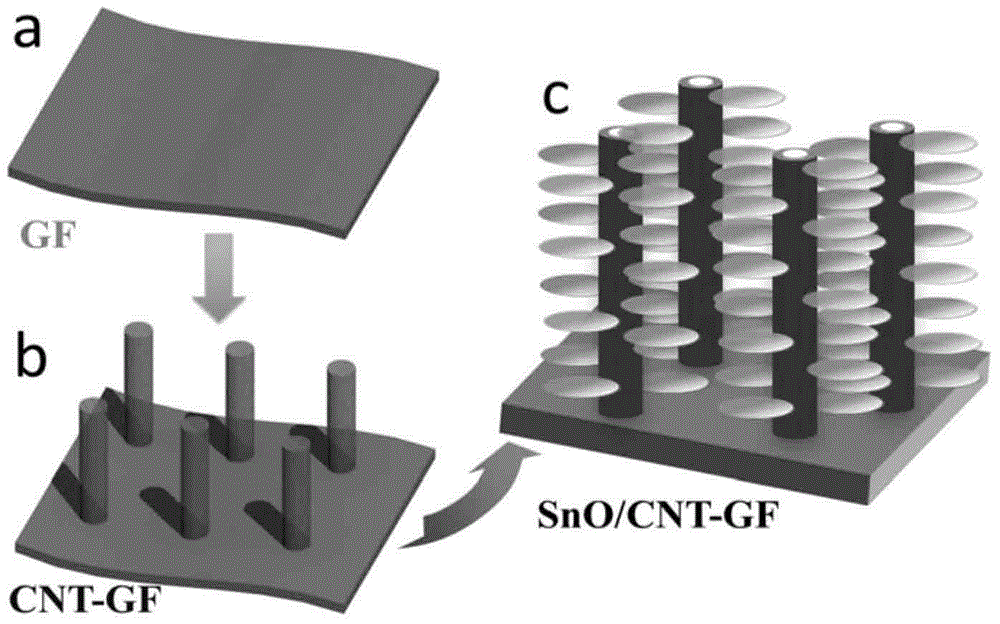

Method for preparing flexible stannous oxide nano sheet/carbon nanotube-graphene three-dimensional composite material

A technology of stannous oxide and carbon nanotubes, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor cycle performance, low rate, and low specific capacity of lithium battery anode materials , to achieve high conductivity, improve utilization, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

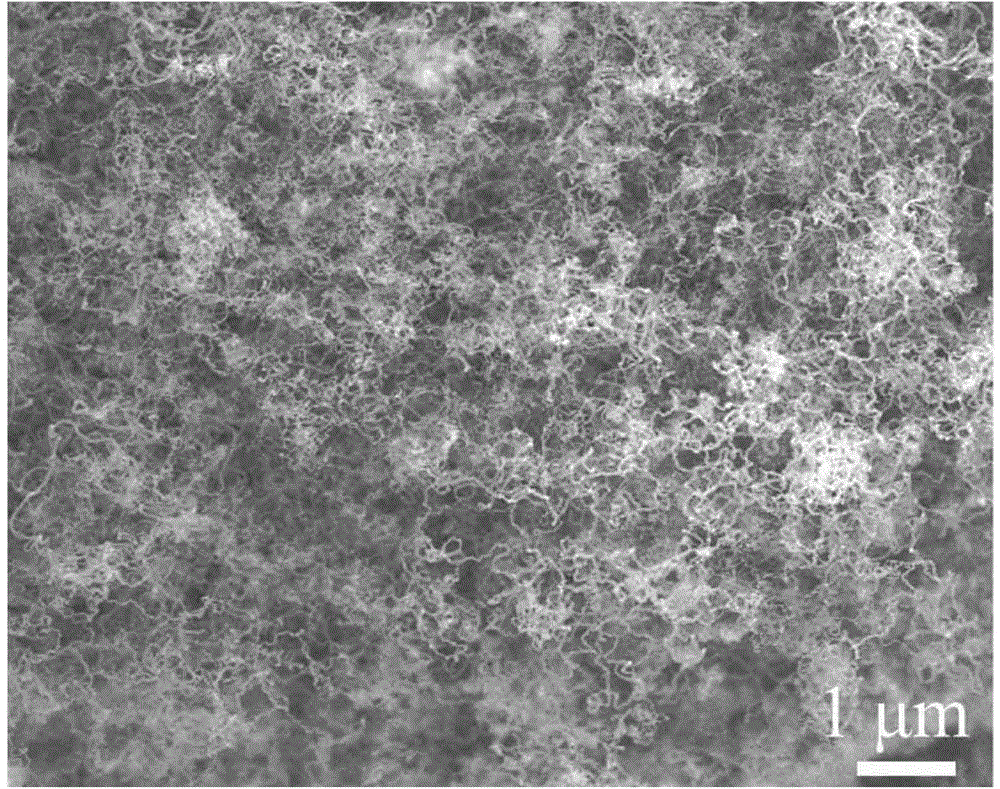

[0050] Embodiment 1: This embodiment is a preparation method of a flexible stannous oxide nanosheet / carbon nanotube-graphene three-dimensional composite material, which is prepared according to the following steps:

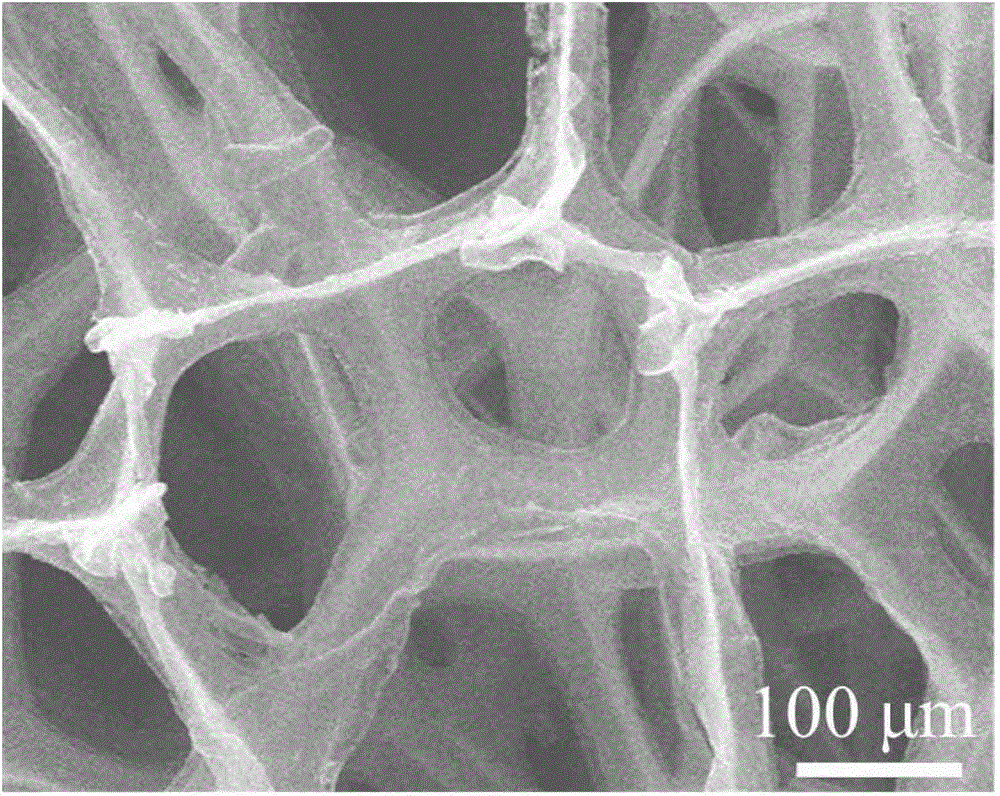

[0051] 1. Preparation of three-dimensional graphene foam:

[0052] ①. Clean the nickel foam with absolute ethanol for 3 to 5 times to obtain the nickel foam after cleaning with absolute ethanol; then put the nickel foam after cleaning with absolute ethanol into a quartz tube furnace, and then add argon and hydrogen Flow rate of 500sccm and 200sccm into the quartz tube furnace respectively, and then heat the quartz tube furnace to 1000℃~1050℃ at a heating rate of 10℃ / min~15℃ / min, and then heat it at a temperature of 1000℃~ React at 1050°C and a mixed gas atmosphere of argon and hydrogen for 4 minutes to 6 minutes; obtain foamed nickel with the oxide layer removed;

[0053] ②. Feed methane, hydrogen and argon into a quartz tube furnace at a temperature of 1000°C to...

specific Embodiment approach 2

[0080] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mixed solution A described in step one 4. is to be that 25%~30% ferric nitrate aqueous solution and the mass fraction are mixed by the hydrochloric acid of 37% by mass fraction Prepared; in the mixed solution A, the volume ratio of the ferric nitrate aqueous solution with a mass fraction of 25% to 30% and the hydrochloric acid with a mass fraction of 37% is 8:1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0081] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the Ni(NO 3 ) 2 ·6H 2 The volume ratio of the amount of O substance to deionized water is (1mmol-100mmol): 40mL. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com