Treatment method for alkali liquor oxidation regeneration tail gas containing mercaptide

A treatment method and technology for saline-alkali liquid, which are applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of substandard discharge, long process, pollute the environment, etc., and achieve recycling, simple and reliable process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

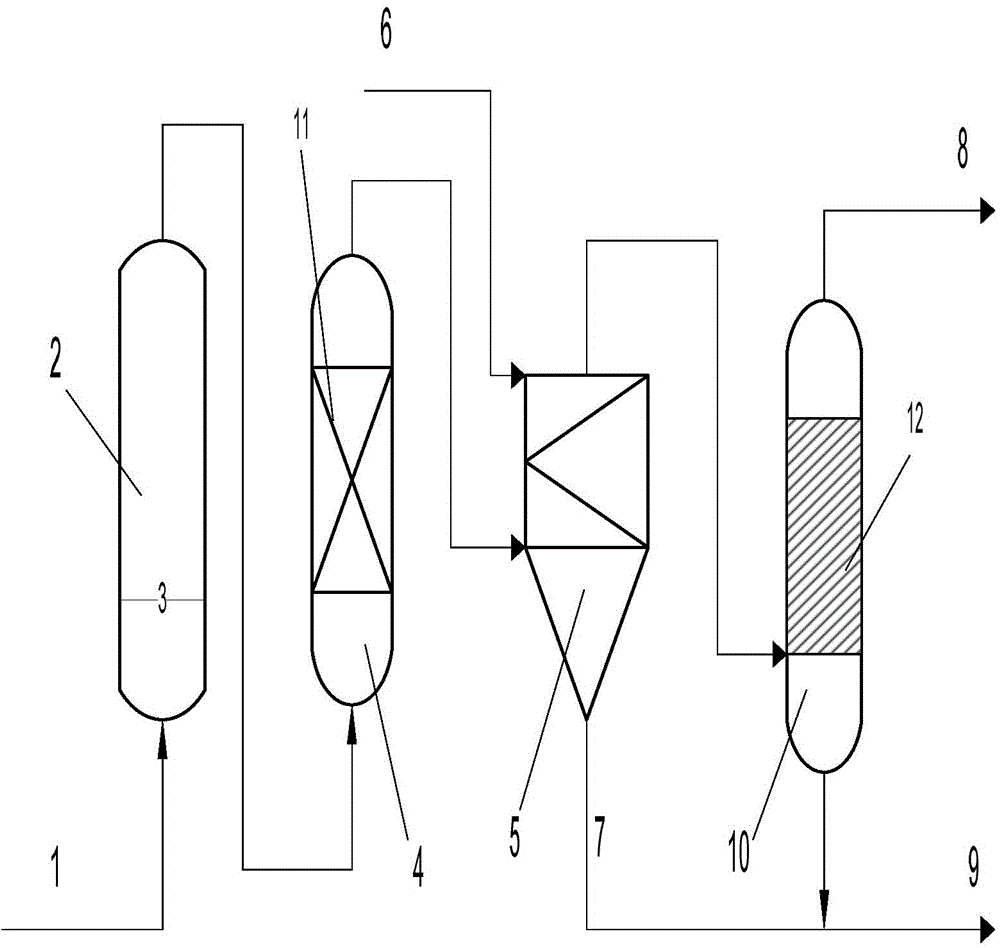

[0015] like figure 1 As shown, the oxidative regeneration tail gas 1 containing mercaptan alkali solution to be treated enters from the bottom of the water washing tank (2), passes through the gas distribution plate 3, and exits from the top of the water washing tank after washing and removing alkali, enters the dehydration tank 4 from the bottom, passes through the desiccant 11 After drying and dehydration, it enters the supergravity separator 5, and after being fully contacted with the absorbent diesel oil 6, the exhaust gas enters the absorbed exhaust diesel oil separation and recovery tank 10, and after oil and gas separation, the exhaust gas 8 is purified and discharged up to the standard, and the absorbed rich diesel oil 7, 9 Sent to hydrogenation unit for desulfurization. The tail gas diesel oil separation and recovery tank 10 is filled with wire mesh or microsphere particles 12 .

Embodiment 2

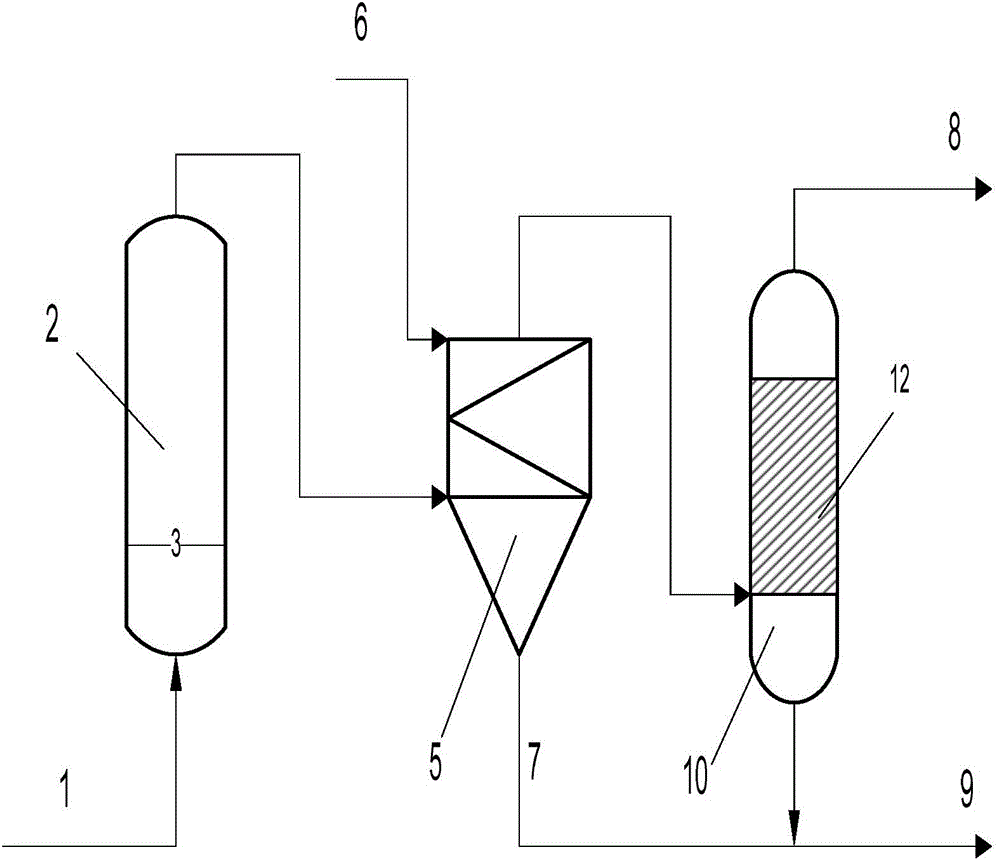

[0017] like figure 2 As shown, the oxidative regeneration tail gas 1 containing mercaptan alkali solution to be treated enters from the bottom of the water washing tank 2, passes through the gas distribution plate 3, and exits from the top of the water washing tank after washing and removing alkali, enters the supergravity separator 5, and is mixed with the absorbent diesel oil 6 After full contact, the tail gas enters the absorbed tail gas diesel oil separation and recovery tank 10, and after oil and gas separation, the exhaust gas 8 is purified and discharged up to the standard, and the absorbed rich diesel oil 7, 9 is sent to the hydrogenation device for desulfurization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com