Annulus protective liquid of annulus mechanical seat sealed oil-gas well and applications thereof

A technology of annulus protection fluid and annulus machinery, applied in wellbore/well parts, drilling composition, earthwork drilling and production, etc., can solve problems such as pressure relief, wellhead topping, easy aging, etc., and achieve compression Large degree, convenient pressure relief and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In a liquid mixing tank with a capacity of 10L, 10% of emulsifier oxyethylene sorbitan monooleate span-80 (Jiangsu Haian Petrochemical Plant) was sequentially added in terms of mass percentage, and 0.5% of salt-resistant High-temperature foaming agent polyoxyethylene alkyl alcohol ether (Jiangsu Haian Petrochemical Plant), 0.3% foam stabilizer plant gum heteroglycan KD-03 (Yangzhou Runda Oilfield Chemical Agent Co., Ltd.), 0.1% layering Regulator polyoxypropylene polyoxyethylene ether (Jiangsu Haian Petrochemical Plant), 28% 26# industrial grade white oil (Shanghai Best Chemical Co., Ltd.), 0.5% corrosion inhibitor alkynyloxymethyl quaternary ammonium salt IMC -80BH (Shenyang Zhongke Mingyang Corrosion and Protection Co., Ltd.), the rest is water, 3000rpm continuous stirring and dosing; then feed nitrogen with a volume percentage of 8-10%, 3000rpm continuous stirring for 30min, to form a uniform foam emulsion. Put the foam emulsion at room temperature 25°C, pass the st...

Embodiment 2

[0049] In terms of mass percentage, formulating liquid according to components: 14% emulsifier oxyethylene sorbitan tristearate span65 (Jiangsu Haian Petrochemical Factory), 0.1% nonionic surfactant foaming agent alkyl Phenolic polyoxyethylene ether (Jiangsu Haian Petrochemical Plant), 0.1% foam stabilizer polyacrylamide HPAM (Henan Yiqing Chemical Plant), 0.2% layering regulator phenolamine resin ether (Jiangsu Haian Petrochemical Plant ), 25% of 26# industrial grade white oil (Shanghai Best Chemical Co., Ltd.), 0.1% of corrosion inhibitor alkynyloxymethyl quaternary ammonium salt (Shenyang Zhongke Mingyang Corrosion and Protection Co., Ltd.), and the rest is water.

[0050] Table 2 Components of annular protection fluid

[0051]

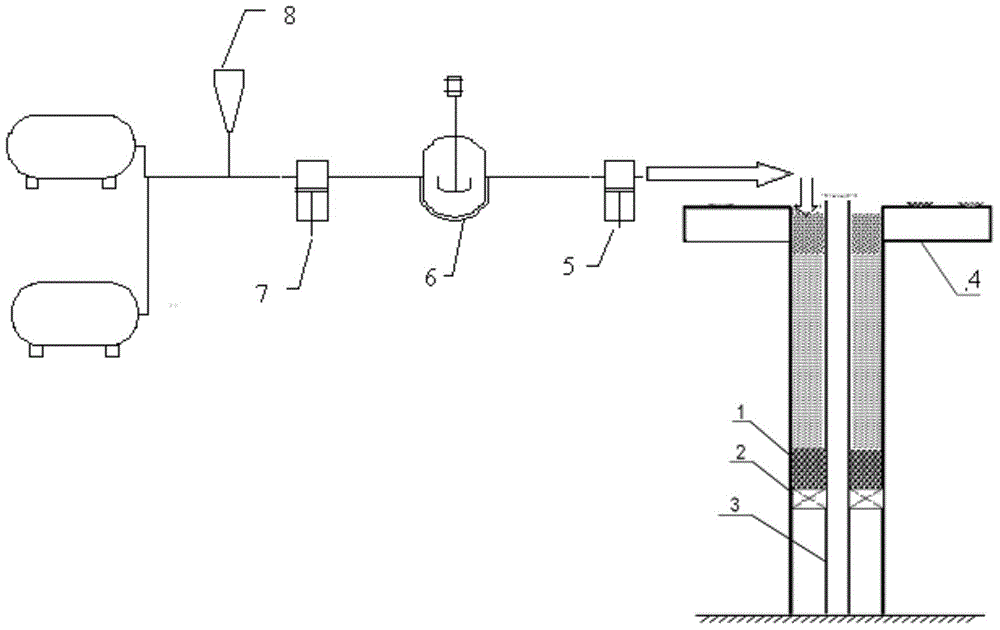

[0052] see figure 1 , use the dosing pump truck 7 to prepare the liquid from the dosing port 8 according to the formula in the liquid mixing tank 6, and continue to stir and add the medicine to form a foam emulsion with a uniform phase state (n...

Embodiment 3

[0054] In terms of mass percentage, formulating liquid according to components: 12% polyoxyethylene sorbitan trioleate Span85 (Jiangsu Haian Petrochemical Plant), 0.5% foaming agent polyoxyethylene alkyl alcohol ether (Jiangsu Haian Petrochemical plant), 0.2% carboxymethylcellulose sodium salt CMC foam stabilizer (Yangzhou Runda Oilfield Chemical Agent Co., Ltd.), 0.2% layering regulator hydrazine oxide polyether (Jiangsu Haian Petrochemical Plant), 25% commercially available gas oil, 0.8% corrosion inhibitor alkynyloxymethyl quaternary ammonium salt (Shenyang Zhongke Mingyang Corrosion and Protection Co., Ltd.), and the rest is water.

[0055] Table 3 Components of annular protection solution

[0056]

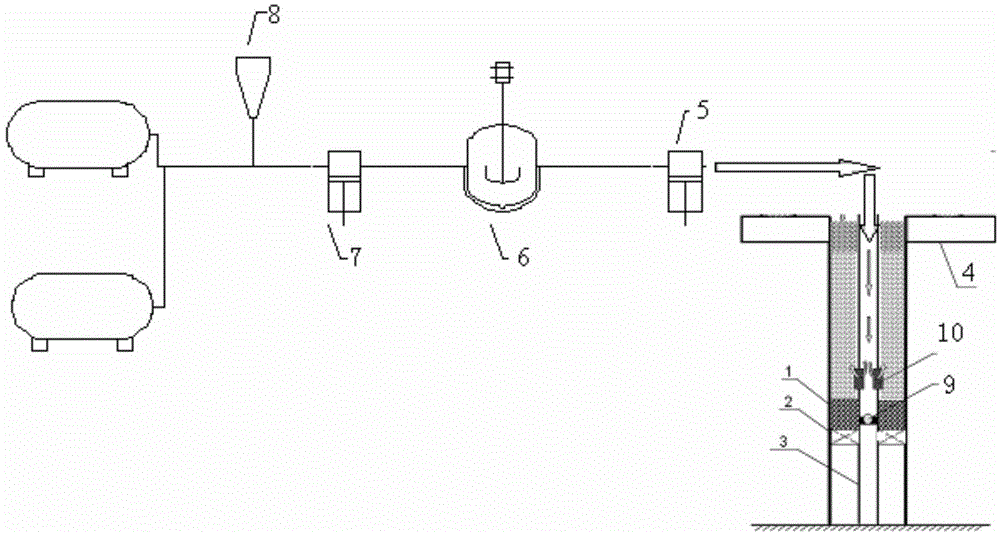

[0057] see figure 2 , use the dosing pump truck 7 to prepare the liquid in the liquid mixing tank 6 according to the formula from the dosing port 8, continue to stir and add the medicine to form a foam emulsion, and feed in a chemically stable gas with a uniform phase sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com