Extraction method of oil reservoir microbial genome DNA

An extraction method and microbial technology, applied in recombinant DNA technology, DNA preparation and other directions, can solve the problems of reducing DNA yield and purity, a large number of membranes, and the impact of extraction operations, and achieve improved sample processing capacity, increased possibility, and extraction cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

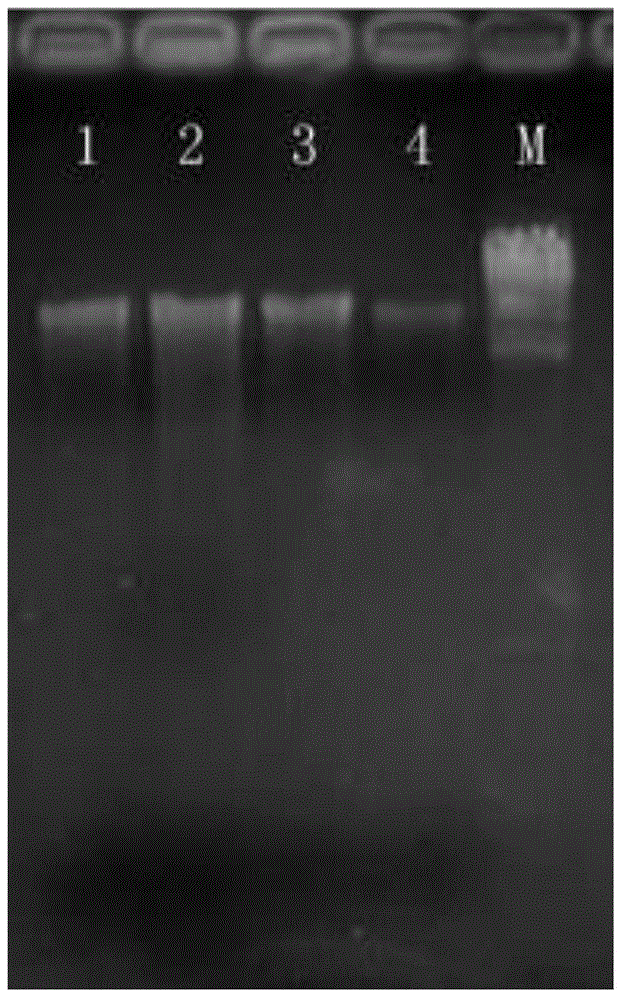

Image

Examples

Embodiment 1

[0024] (1) Organic solvent extraction removes crude oil and releases microorganisms at the oil-water interface

[0025] Take 3L of each oil well output fluid and 3L of one injected water sample. Add 500ml of petroleum ether to the liquid phase of the sample, shake and mix well, and then let it stand for 1 hour to separate the organic phase and the aqueous phase, and remove the lower aqueous phase.

[0026] (2) Collect bacteria

[0027] The obtained aqueous phase was filtered through a 0.22 μm hollow cellulose membrane filter by using a peristaltic pump to control the pressure to 0.5 MPa, and bacteria were collected.

[0028] (3) Lysis of microbial cells

[0029] First, cut the hollow cellulose membrane of the filter, mix it with quartz sand, put it into a centrifuge tube containing 800 μl extraction buffer, add 450 μl 1xTE, 50 μl 10 mg / mL lysozyme and 10 μl 100 mg / mL helicase, and mix well by blowing and aspiration , incubate at 37°C for 1 hour, invert and mix every 15 minut...

Embodiment 2

[0034] (1) Organic solvent extraction removes crude oil and releases microorganisms at the oil-water interface

[0035] Take 3L of each oil well output fluid and 3L of one injected water sample. Add 600ml of petroleum ether to the liquid phase of the sample, shake and mix well, and then let it stand for 2 hours to separate the organic phase and the aqueous phase, and remove the lower aqueous phase.

[0036] (2) Collect bacteria

[0037] The obtained aqueous phase was filtered through a 0.22 μm hollow cellulose membrane filter by using a peristaltic pump to control the pressure to 0.5 MPa, and bacteria were collected.

[0038] (3) Lysis of microbial cells

[0039] First, cut the hollow cellulose membrane of the filter, mix it with quartz sand, put it into a centrifuge tube containing 1000 μl extraction buffer, add 450 μl 1xTE, 50 μl 10 mg / mL lysozyme and 10 μl 100 mg / mL helicase, and mix by pipetting , incubate at 37°C for 1 hour, invert and mix every 15 minutes, then add 600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com