Method utilizing conductive polymer porous separating membrane to recycle metals from electronic wastes

A conductive polymer and porous separation membrane technology, applied in the direction of improving process efficiency, can solve the problems of ecological environment and human health pollution, hazards, etc., and achieve the effects of improving recovery efficiency, simplifying processing equipment, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Mix polyaniline and polyvinylidene fluoride at a mass ratio of 3:1, and then add the polymer mixture to 1-form at a solid-to-liquid ratio of 1:5 (polymer mixture / g: solvent / ml) In the base-2-pyrrolidone, sonicated at 60°C for 1 hour to form a polyaniline-polyvinylidene fluoride mixed solution.

[0037] (2) Take 2ml of the polyaniline-polyvinylidene fluoride mixed solution obtained in step (1) and drop it on a clean glass plate and spread it flat on the surface of the glass plate to form a liquid polymer with a width of about 2cm and a length of about 10cm The coating is then put into deionized water together with the glass plate to quickly solidify the polymer coating to form a separation film and fall off the glass plate.

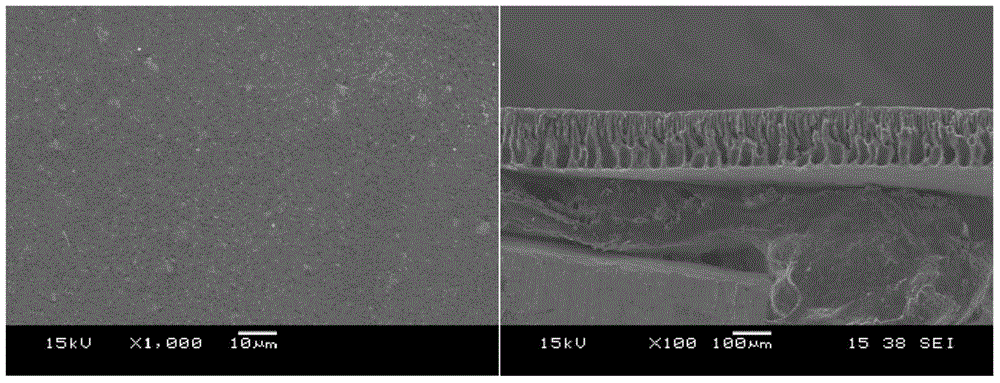

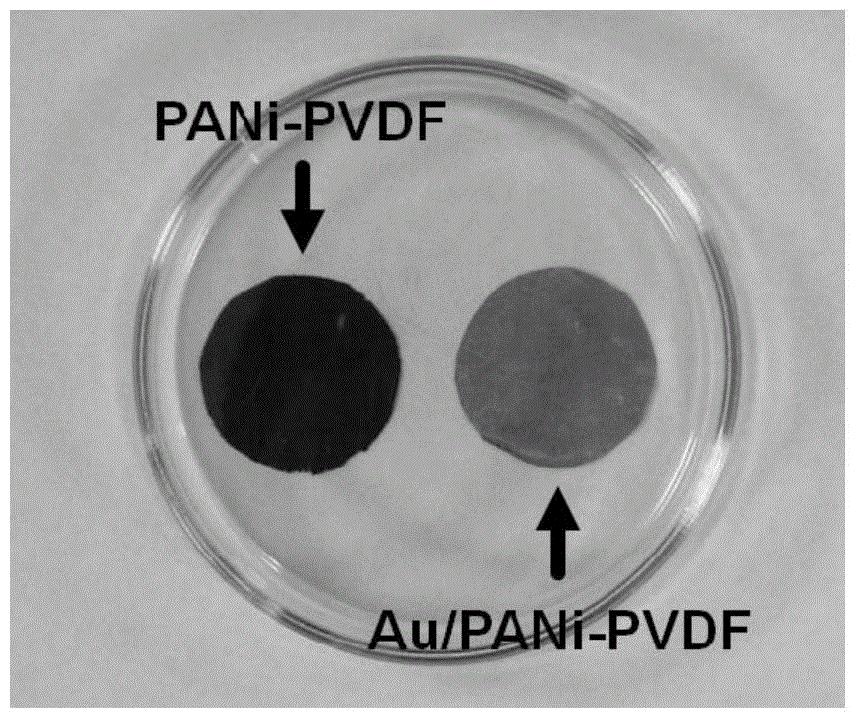

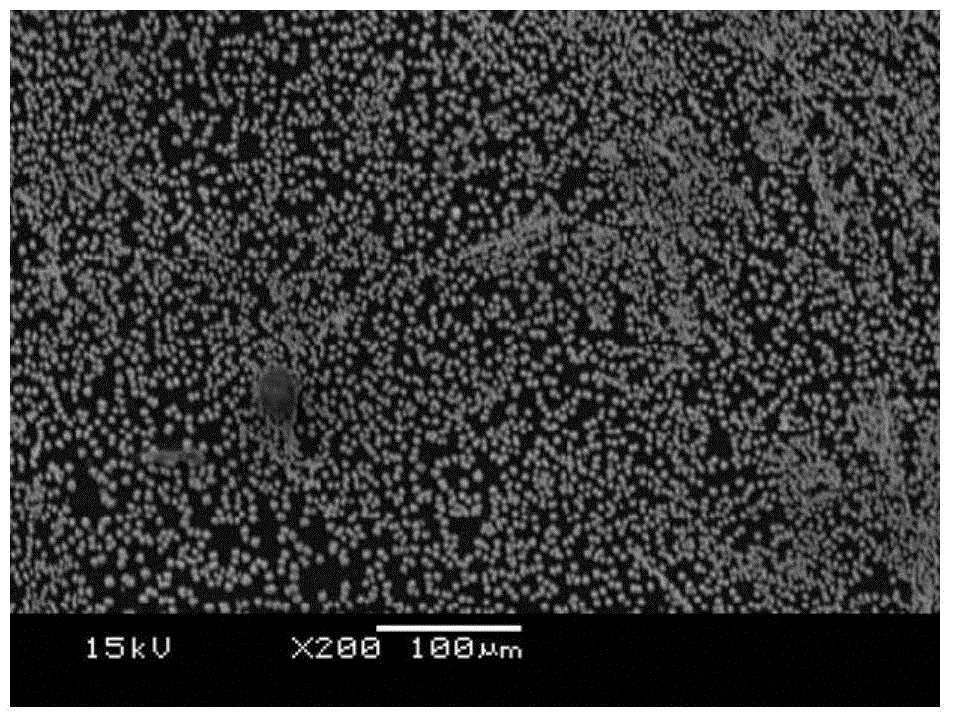

[0038] (3) Immerse the solid polyaniline-polyvinylidene fluoride separation membrane obtained in step (2) in sufficient deionized water to completely remove the organic solution and form micropores in the separation membrane to obtain polyaniline-pol...

Embodiment 2

[0047] The process of Examples 2 and 3 is basically the same as that of Example 1, except that in Example 2, polyaniline and polyvinylidene fluoride are mixed at a mass ratio of 1:1, and in Example 3, polyaniline and polyvinylidene fluoride are mixed. Mix according to the mass ratio of 1:3.

[0048] Observe the change with time of the gold content of the hydrochloric acid leaching solution in the above-mentioned embodiment 1-3 in the process of step (4), and obtain the following Figure 4 The reaction kinetics diagram of the gold component shown. It can be seen from this figure that the use of polyaniline-polyvinylidene fluoride porous separation membranes can conveniently and efficiently recover the gold component in the acid leaching solution.

[0049] In the same way, after experiments, it is found that the above-mentioned polyaniline-polyvinylidene fluoride porous separation membrane can conveniently and efficiently recover mercury, silver, tin, chromium, platinum, palladium a...

Embodiment 4

[0051] (1) Mix the polypyrrole and polyimide according to the mass ratio of 1:1, and then add the polymer mixture to 1-form at a solid-to-liquid ratio of 1:20 (polymer mixture / g: solvent / ml) In -2-pyrrolidone, sonicate at 60°C for 1 hour to form a polypyrrole-polyimide solution;

[0052] (2) Take 2ml of the polypyrrole-polyimide mixed solution obtained in step (1) and drop it on a clean glass plate, and use special tools to spread it on the surface of the glass plate to form a width of about 2cm and a length of about 10cm The liquid polymer coating is then put into deionized water together with the glass plate, so that the polymer coating is quickly solidified to form a separation film and fall off the glass plate;

[0053] (3) Immerse the solid polypyrrole-polyimide separation membrane obtained in step (2) in sufficient deionized water to completely remove the organic solution and form micropores in the separation membrane to obtain polypyrrole-polyimide Porous separation membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com