Preparation method of P type transparent Ca3Co4O9 conductive film

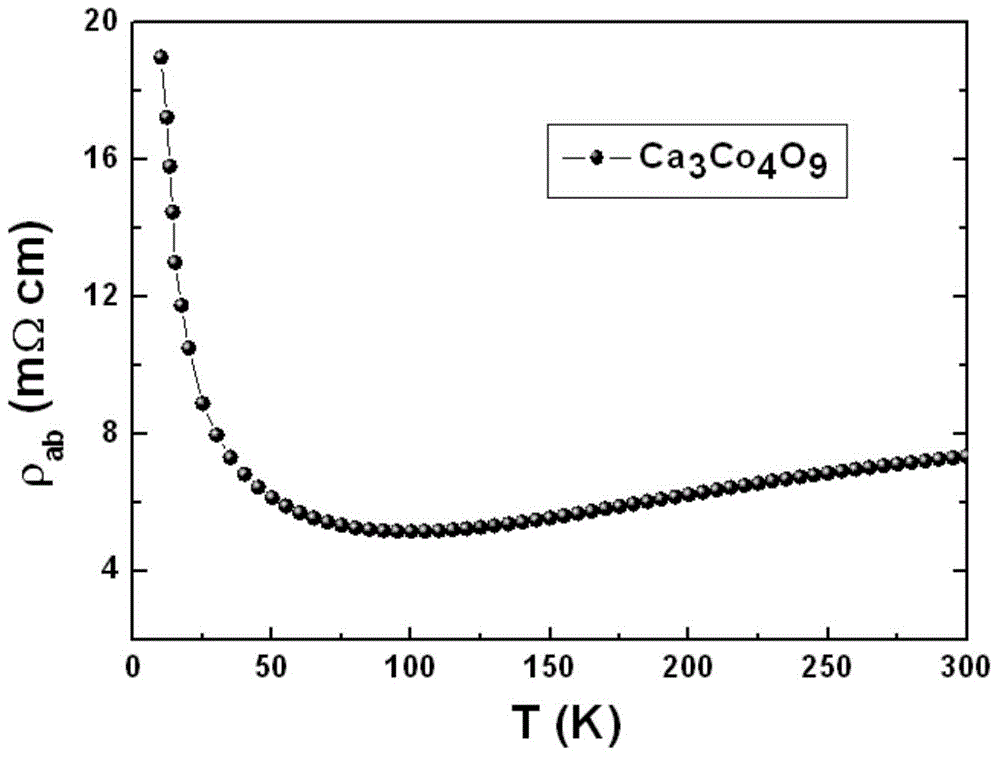

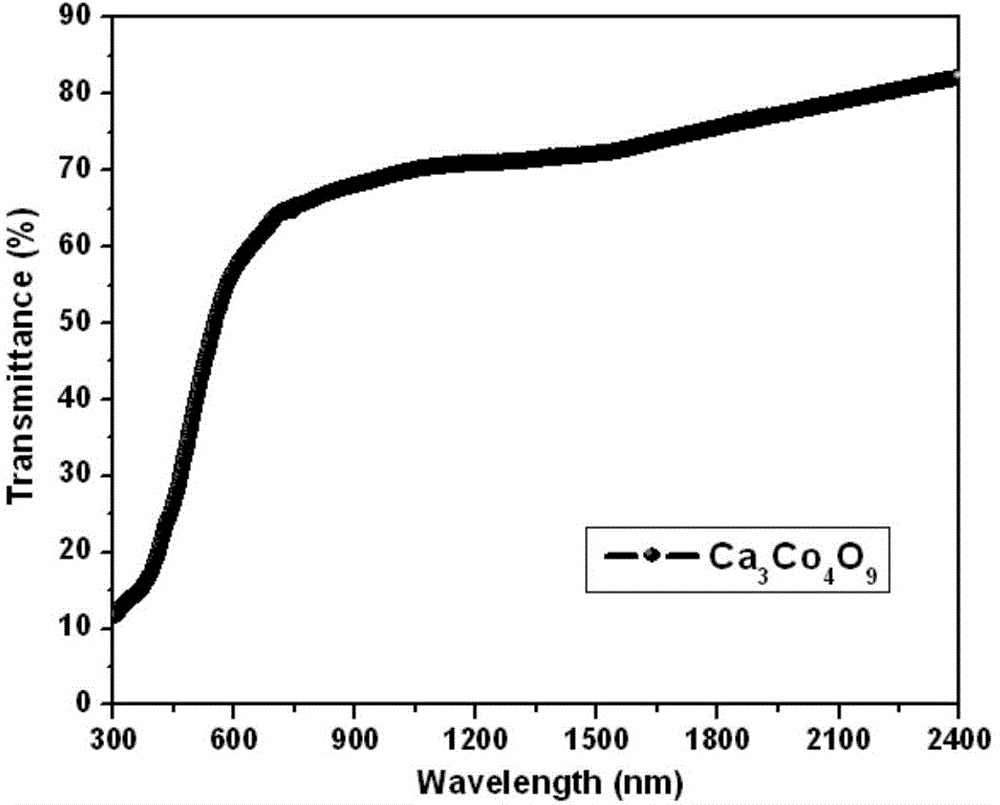

A conductive thin film and transparent technology, which is applied in the field of preparation of P-type transparent Ca3Co4O9 conductive thin film, can solve the problems of preparation process stability and repeatability improvement, electrical conductivity and other problems, and achieve good crystal quality, high photoelectric quality factor, Good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with examples.

[0022] p-type transparent conductive film Ca 3 co 4 o 9 The preparation method is carried out according to the following steps:

[0023] A, the high-purity CaCO 3 ,Co 3 o 4 According to the molar ratio of calcium to cobalt 3:4, weighing, mixing, grinding,

[0024] Tablet molding, pre-sintering in a tube-type high-temperature annealing furnace at 900 ° C for 10 hours, and naturally cooling to

[0025] At room temperature, repeat the pre-sintering 2-3 times in this way to obtain the Ca used for deposition 3 co 4 o 9 target;

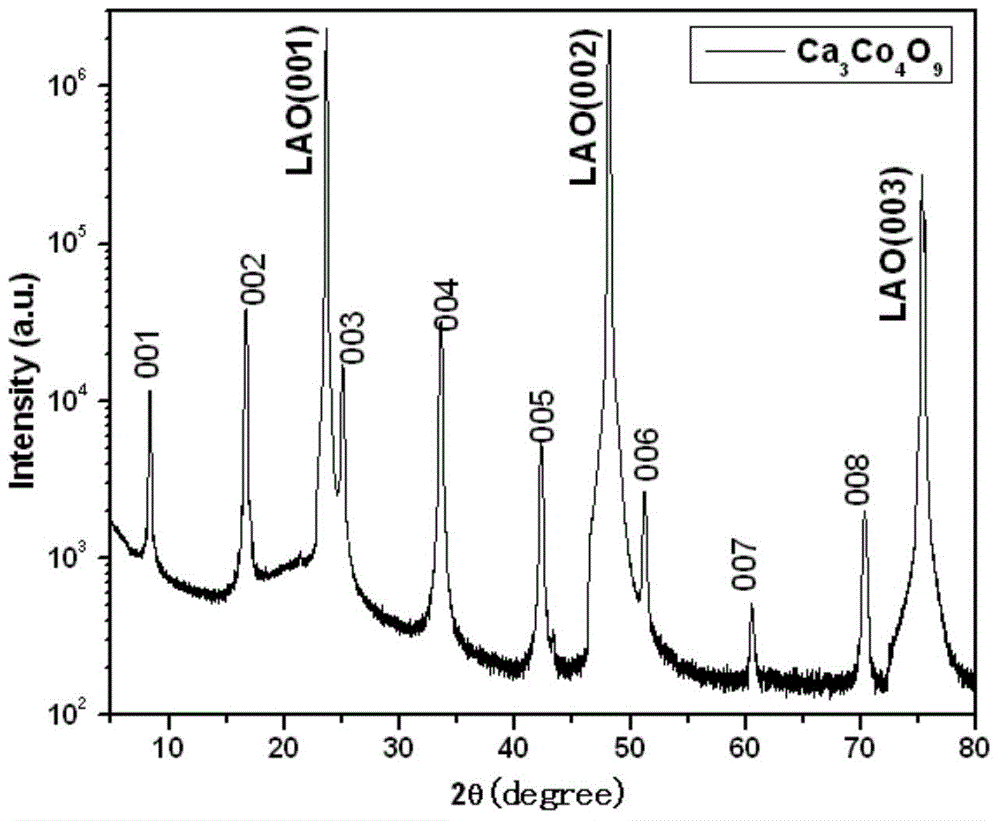

[0026] B, the prepared Ca 3 co 4 o 9 The target material is placed in the PLD cavity, deposited by pulsed laser, in LaAlO 3 The substrate deposits Ca according to the above parameters 3 co 4 o 9 film.

[0027] C. Annealing at high temperature for 2 hours in a high-purity oxygen atmosphere at an annealing temperature of 820°C to obtain Ca grown al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com