Normal-temperature-storage processed cheese and preparation method thereof

A technology of processed cheese and normal temperature, which is applied in the field of normal temperature storage processed cheese and its preparation, which can solve the problems of cheese sales and consumption restrictions, and achieve the effects of good nutritional and health functions, long shelf life, and increased sales range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

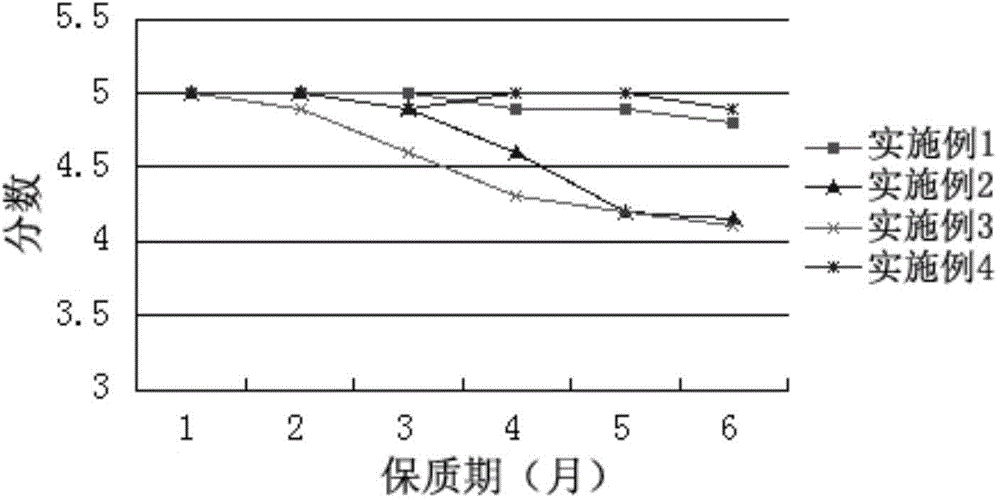

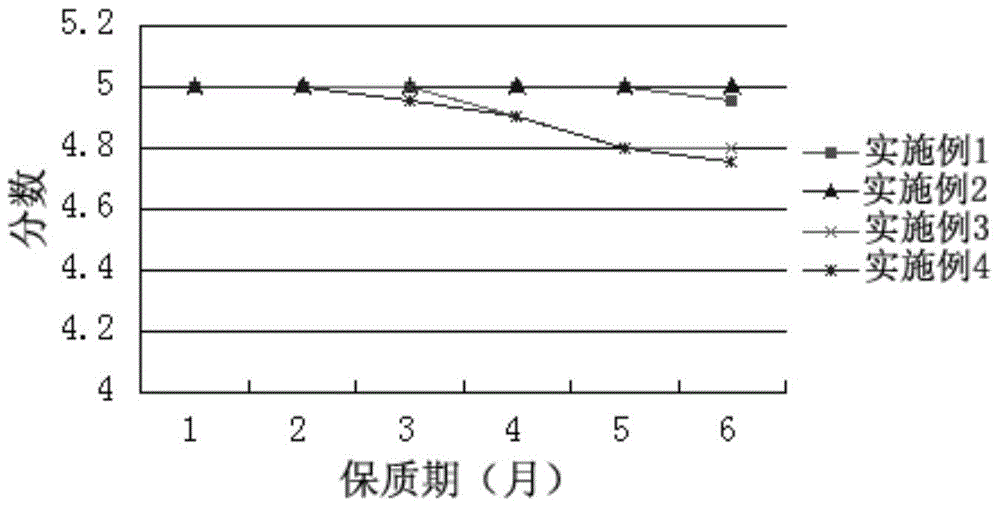

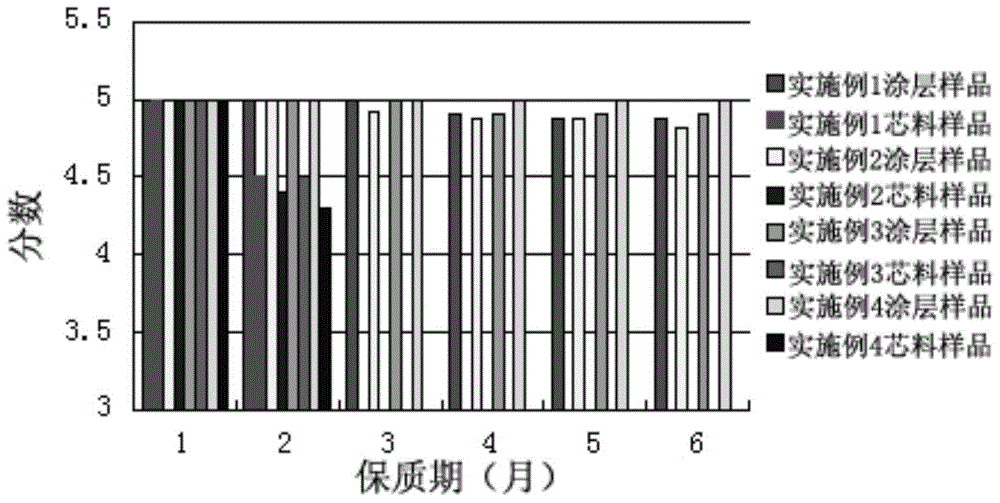

Examples

Embodiment 1

[0046] Example 1 Processed cheese stored at room temperature (original flavor) and its preparation method

[0047] This example provides a normal temperature storage type processed cheese (plain taste), which is composed of a surface coating and a core, based on 1000 parts by weight of raw materials, the raw material composition of the normal temperature storage type processed cheese includes:

[0048] 150 parts by weight of cheddar cheese, 30 parts by weight of sucrose, 5 parts by weight of fructose syrup, 5 parts by weight of powdered sugar, 200 parts by weight of whole milk powder, 5 parts by weight of anhydrous butter, 15 parts by weight of starch, 20 parts by weight of dextrin , 10 parts by weight of gum arabic, 0.1 parts by weight of carrageenan, 1 part by weight of potassium sorbate, 0.1 part by weight of lactobacillus streptococcus, 13 parts by weight of sodium citrate, 1 part by weight of disodium hydrogen phosphate, 1 part by weight of sodium tripolyphosphate , 1 par...

Embodiment 2

[0057] Example 2 Normal temperature storage type processed cheese (low fat) and its preparation method

[0058] This example provides a normal temperature storage type processed cheese (low fat), which is composed of a surface coating and a core, based on 1000 parts by weight of raw materials, the raw material composition of the normal temperature storage type processed cheese includes:

[0059] 300 parts by weight of mozzarella cheese, 20 parts by weight of sucrose, 5 parts by weight of fructose syrup, 5 parts by weight of powdered sugar, 5 parts by weight of whole milk powder, 5 parts by weight of starch, 1 part by weight of dextrin, 1 part by weight of gum arabic , 0.1 parts by weight of guar gum, 0.1 parts by weight of locust bean gum, 0.1 parts by weight of potassium sorbate, 1 part by weight of lactobacillus streptococcus, 6 parts by weight of sodium pyrophosphate, 6 parts by weight of sodium tripolyphosphate, 1 part by weight of sodium citrate parts by weight, and the b...

Embodiment 3

[0068] Example 3 Processed cheese stored at room temperature (no sucrose) and its preparation method

[0069] This example provides a normal temperature storage type processed cheese (no sucrose), which is composed of a surface coating and a core, based on 1000 parts by weight of raw materials, the raw material composition of the normal temperature storage type processed cheese includes:

[0070] 500 parts by weight of gouda cheese, 100 parts by weight of maltose, 80 parts by weight of xylitol, 10 parts by weight of dextrin, 1 part by weight of gum arabic, 8 parts by weight of carrageenan, 8 parts by weight of locust bean gum, and 0.1 part by weight of monoglycerides , 1 weight part of potassium sorbate, 1 weight part of lactobacillus streptococcus, 6 weight parts of disodium hydrogen phosphate, 6 weight parts of sodium hexametaphosphate, 6 weight parts of trisodium phosphate, and the remainder of drinking water.

[0071] The preparation method of the normal temperature storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com