Micronization and crystal form of ticagrelor and preparation method and pharmaceutical application of crystal form of ticagrelor

A technology of ticagrelor and micronization, applied in the field of medicine, can solve the problems of uniform mixing of difficult pharmaceutical excipients, low yield, lack of brittleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

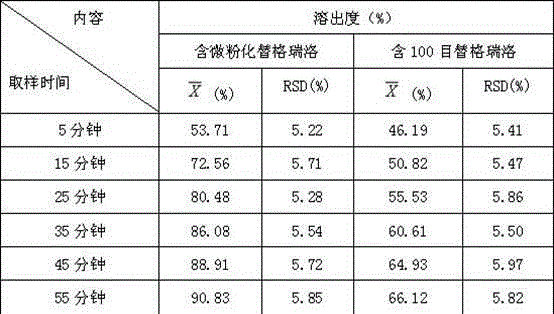

Image

Examples

Embodiment 1

[0109] Example 1. Micronized ticagrelor and its preparation

[0110] Preparation method 1. Take 1g of ticagrelor raw material and add 15ml of absolute ethanol to dissolve it completely, slowly add (or drop) into 300ml of distilled water, and stir at the same time, the stirring speed is 800r / min, ticagrelor immediately precipitates and dispersed in water, filtered with a microporous filter, stirred or rinsed with distilled water for 2 to 4 times, filtered, and dried at 40 to 70°C to constant weight to obtain micronized ticagrelor with a yield of 97%. The above-mentioned powder is taken, X-ray diffraction measurement and powder particle size detection are carried out, and the average particle size of the powder is 3-4 microns.

[0111] Preparation method 2. Take 1 g of ticagrelor raw material and add 20 ml of absolute ethanol to dissolve it completely, add 0.3% (w / v) needle and stir with activated carbon for 10 minutes to decolorize, filter and decarbonize with a microporous mem...

Embodiment 2

[0113] Example 2. Micronized ticagrelor and its preparation

[0114] Take 1g of ticagrelor raw material and add 15ml of methanol to make it completely dissolved, add it into 500ml of distilled water, and stir at the same time, the stirring speed is 900r / min, ticagrelor is immediately precipitated and dispersed in water, filtered with a microporous filter, Stir washing or rinsing with distilled water for 2-4 times, filter, and dry at 50-80°C to constant weight to obtain micronized ticagrelor with a yield greater than 97.5%. The above powder is taken, X-ray diffraction measurement and powder particle size detection are carried out, and the average particle size of the powder is 3-5 microns.

Embodiment 3

[0115] Example 3. Micronized ticagrelor and its preparation

[0116] Take 1g of ticagrelor raw material, add 22ml of acetone and heat it to 50°C to dissolve it completely, add it into 400ml of distilled water at 50°C, and keep stirring at 48-55°C at the same time, the stirring speed is 600r / min, ticagrelor Ticagrelor is immediately precipitated and dispersed in water, filtered while hot, stirred or rinsed with distilled water for 2 to 4 times, filtered, and dried at 60 to 70°C to constant weight to obtain micronized ticagrelor. The above powder is taken, X-ray diffraction measurement and powder particle size detection are carried out, and the average particle size of the powder is 3-6 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com