A method for the determination of acid scarlet gr in paper food packaging materials

A technology of food packaging and acid scarlet, applied in the field of physical and chemical testing, to achieve the effect of easy operation, elimination of interference, and improvement of repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

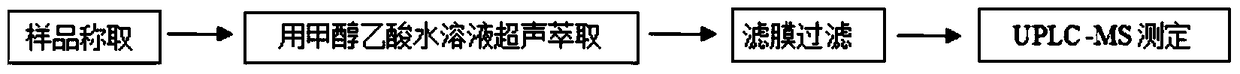

Method used

Image

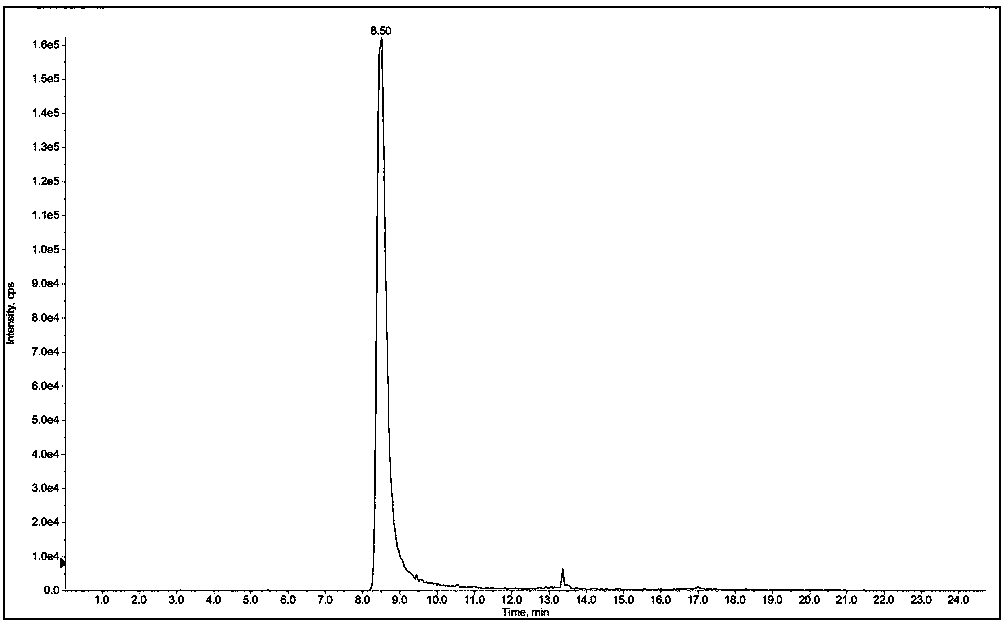

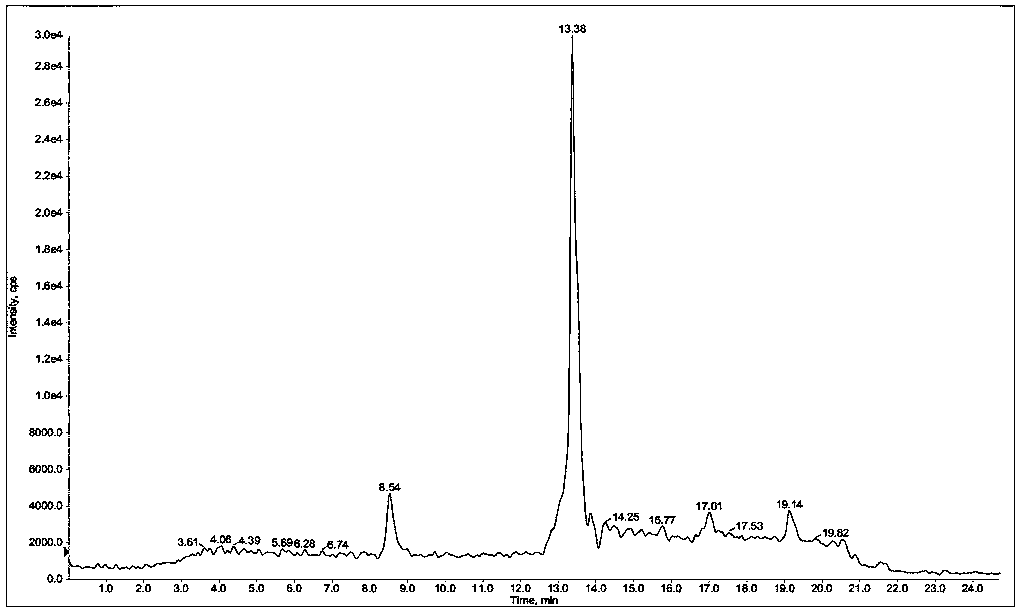

Examples

Embodiment 1

[0025] Instrument and reagent of the present invention, material:

[0026] U.S. Agilent1290 / 6460 ultra-high performance liquid chromatography-quadrupole mass spectrometer; chromatographic column: AgilentC18 (4.6×150mm, 5μm), 0.22μm microporous filter membrane, ultrasonic cleaner;

[0027] Ultrapure water (18MΩ), methanol (chromatographically pure, Bailingwei Chemical Reagent Company), acetic acid and ammonium acetate were all of superior grade.

[0028] Preparation of standard working curve: use methanol to make Acid Scarlet GR standard stock solution into 0.1, 0.5, 1, 5, 10, 20μg / L series concentrations, and compare the peak area of the analyte with the peak area of the internal standard (Y) The concentration (X) of the analyte was linearly regressed to make a standard curve.

[0029] Sample pretreatment: Weigh 1.0g sample (accurate to 0.0001g), place it in a 50ml ground-mouth Erlenmeyer flask, accurately add 30mL extract solution (1:3:6), ultrasonically extract for 15-3...

Embodiment 2

[0038] Using methanol solution as a solvent, prepare a standard working curve, inject 10 consecutive samples with the lowest concentration standard solution, calculate the standard deviation, and use 3 times and 10 times the standard deviation to represent the detection limit and quantification limit respectively. The results are shown in Table 3:

[0039] Table 3 method standard curve equation and quantitative detection limit

[0040]

Embodiment 3

[0042] The intra-day and inter-day parallelism measurements were carried out on the same sample 5 times. The intra-day repeatability results are shown in Table 4, and the intra-day repeatability results are shown in Table 5:

[0043] The intraday repeatability results (mg / kg) of the method in Table 4

[0044]

[0045] The day-to-day repeatability results (mg / kg) of the method in Table 5

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com