Foam dressing containing composite silver-zinc antibacterial material and preparation method of foam dressing

A technology of antibacterial materials and foam plastics, applied in medical science, bandages, absorbent pads, etc., can solve problems such as uneven distribution of drugs and hinder drug efficacy, reduce local bacterial proliferation or local metal poisoning, and protect the end Nervous, concentration-maintaining effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] 3) Preparation of foam dressings containing antibacterial materials: 10.0-20.0 parts by weight of polyether polyol, 0.5-1.5 parts by weight of stannous octoate, 0.5-1.4 parts by weight of dimethylethanolamine, and 0.5-1.8 parts by weight of silicon surfactant , 0.5-1.6 parts by weight of dichloromethane and 0.8-2.6 parts by weight of water are mixed, stirred quickly and evenly, added to the above-mentioned viscous prepolymer, stirred at high speed immediately, after mixing evenly, quickly poured into a foaming mold to foam, and matured for 24 - After 28 hours, the foam dressing containing the composite silver-zinc antibacterial material was obtained.

[0042] The second method for preparing the foam dressing containing the composite silver-zinc antibacterial material comprises the following steps:

[0043] 1) Preparation of composite silver-zinc antibacterial material;

[0044] 2) Preparation of prepolymer: Mix 40.0-53.0 parts by weight of dehydrated polyethylene glyco...

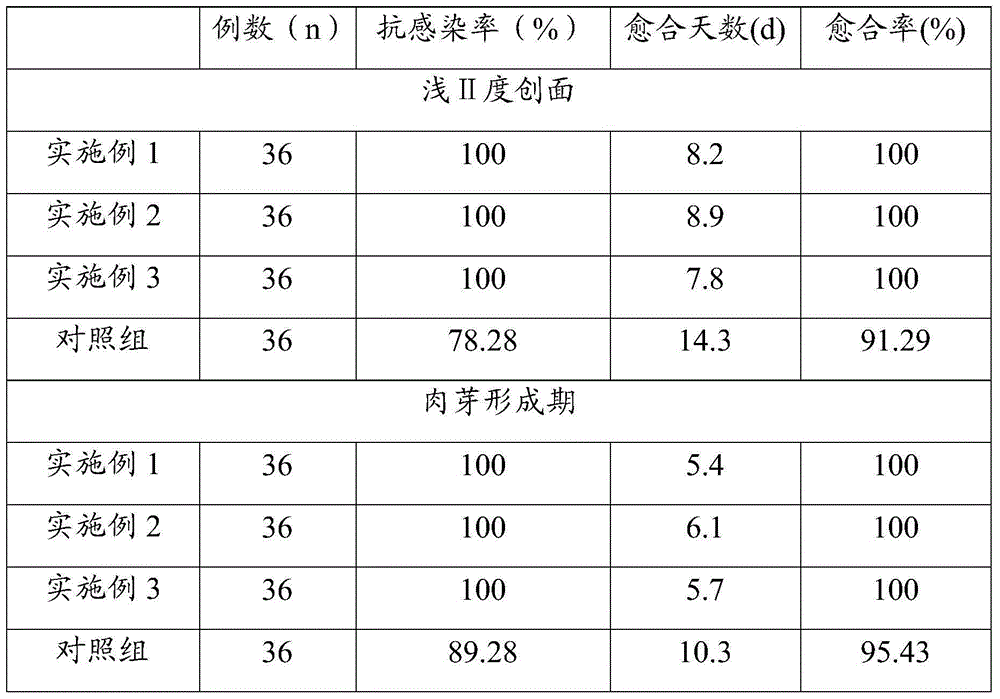

Embodiment 1

[0051] Embodiment 1: adopt method one to prepare the foam dressing containing composite silver-zinc antibacterial material

[0052] 1) Take 220g nanoscale Ag 2 O, 500g nano-ZnO, 280g nano-calcium carbonate, stir and mix evenly, place in a porcelain dish, put in a high-temperature furnace and burn at 800°C for 3 hours, pass through a 200-mesh sieve after cooling, and then obtain a composite silver-zinc antibacterial material ;

[0053] 2) Add 45.0g of dehydrated polyethylene glycol, 2.0g of glycerin, 31.5g of toluene diisocyanate and 1g of the above-mentioned composite silver-zinc antibacterial material into the three-necked bottle, heat and stir, and keep warm at 85°C for 80 minutes to obtain a viscous antibacterial material containing shape prepolymer;

[0054] 3) Take 15g of polyether polyol, 0.9g of stannous octoate, 1.1g of dimethylethanolamine, 1.0g of silicon surfactant, 1.0g of methylene chloride and 1.5g of deionized water, stir quickly and evenly, and add to the abo...

Embodiment 2

[0055] Embodiment 2: Adopt method two to prepare the foam dressing containing composite silver-zinc antibacterial material

[0056] 1) Take 220g nanoscale Ag 2 CO 3 , 500g nanoscale ZnO, 280g nanoscale diatomite, stir and mix evenly, place in a porcelain dish, put in a high temperature furnace and burn at 800°C for 3 hours, pass through a 200-mesh sieve after cooling, and the composite silver-zinc antibacterial Material;

[0057] 2) Add 45.0 g of dehydrated polyethylene glycol, 2.0 g of glycerin, and 31.5 g of toluene diisocyanate into the three-necked flask, heat and stir, and keep the temperature at 80°C for 120 minutes to obtain a viscous prepolymer;

[0058] 3) Get 15g polyether polyol, 0.9g stannous octoate, 1.1g dimethylethanolamine, 1.0g silicon surfactant, 1.0g methylene chloride and 1.5g deionized water and 1g of the above composite silver-zinc antibacterial material, quickly Stir evenly, add to the above viscous prepolymer, then add and immediately stir at high sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com