Preparation method of eucalyptus-based porous carbon-silicon dioxide solid-phase extraction column

A technology of solid-phase extraction column and silica, which is applied in the direction of chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of complex preparation and high cost, and achieve simple preparation process, low cost, and simple experimental equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific steps of the preparation method of the eucalyptus-based porous carbon-silica solid phase extraction column of the present invention are as follows:

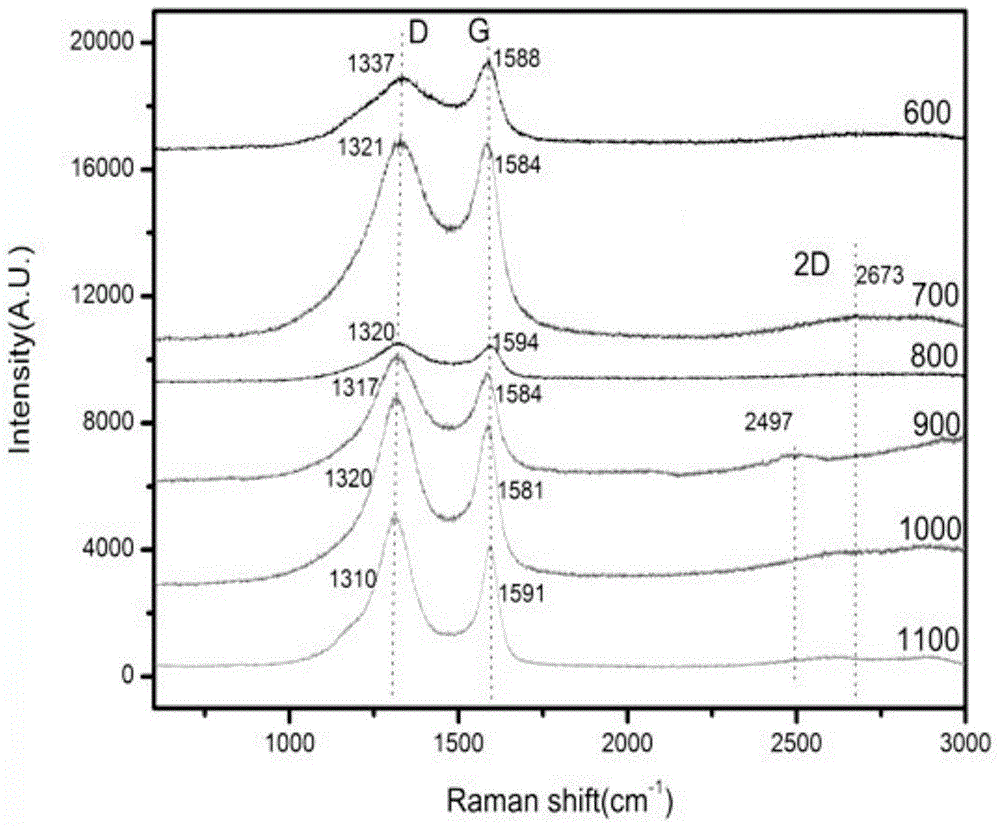

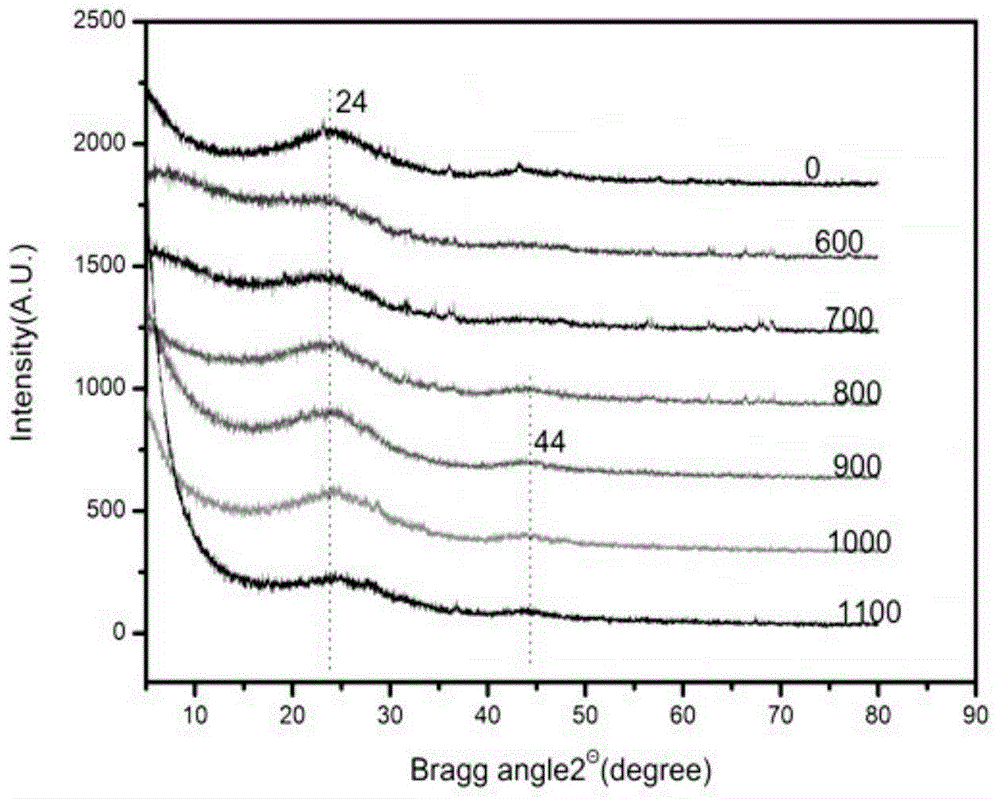

[0032] (1) Preparation of eucalyptus-based porous carbon:

[0033] Take eucalyptus stalk as raw material, add zinc chloride for pretreatment, activate for 1 hour under hydrothermal conditions, wash, dry, and crush to obtain pre-activated eucalyptus stalk powder; add sodium hydroxide to the pre-activated eucalyptus stalk powder , Mix thoroughly to form a column; put the eucalyptus powder column into an atmosphere furnace, protected by nitrogen, and burn it at high temperature; naturally cool, take it out, wash off the sodium hydroxide with hydrochloric acid, and dry to obtain eucalyptus-based porous carbon ;

[0034] (2) Activation of Eucalyptus-based porous carbon:

[0035] Add the mixed acid to the eucalyptus-based porous carbon prepared in step (1), activate it, increase the carboxyl and hydroxyl groups on the surf...

Embodiment 2

[0043] The specific steps of the method for preparing the eucalyptus-based porous carbon-silica solid phase extraction column of the present invention are as follows:

[0044] (1) Preparation of Eucalyptus-based porous carbon:

[0045] Take eucalyptus stem as raw material, add zinc chloride for pretreatment, activate under hydrothermal conditions for 3 hours, wash, dry, and crush to obtain pre-activated eucalyptus stem powder; add sodium hydroxide to the pre-activated eucalyptus stem powder , Mix thoroughly to form a column; put the eucalyptus powder column into an atmosphere furnace, protected by nitrogen, and burn it at high temperature; naturally cool, take it out, wash off the sodium hydroxide with hydrochloric acid, and dry to obtain eucalyptus-based porous carbon ;

[0046] (2) Activation of Eucalyptus-based porous carbon:

[0047] Add mixed acid to the eucalyptus-based porous carbon prepared in step (1), activate it, increase the carboxyl and hydroxyl groups on the surface of ...

Embodiment 3

[0055] The specific steps of the preparation method of the eucalyptus-based porous carbon-silica solid phase extraction column of the present invention are as follows:

[0056] (1) Preparation of eucalyptus-based porous carbon:

[0057] Take eucalyptus stalk as raw material, add zinc chloride for pretreatment, activate for 2 hours under hydrothermal conditions, wash, dry, and crush to obtain pre-activated eucalyptus stalk powder; add sodium hydroxide to the pre-activated eucalyptus stalk powder , Mix thoroughly to form a column; put the eucalyptus powder column into an atmosphere furnace, protected by nitrogen, and burn it at high temperature; naturally cool, take it out, wash off the sodium hydroxide with hydrochloric acid, and dry to obtain eucalyptus-based porous carbon ;

[0058] (2) Activation of Eucalyptus-based porous carbon:

[0059] Add mixed acid to the eucalyptus-based porous carbon prepared in step (1), activate it, increase the carboxyl and hydroxyl groups on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com