Preparation method of Pt-pd alloy type catalyst

A catalyst and alloy-type technology, which is applied in the field of preparation of Pt-Pd alloy catalysts for fuel cells, can solve the problems of small catalyst active area, catalyst corrosion, and large catalyst particle size, so as to improve catalyst activity and durability, avoid The use of organic solvents and the effect of reducing the Pt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In one embodiment of the present invention, the preparation method of the present invention includes the following steps.

[0035] At 20-120°C, take 5-10g of polyoxyethylene-polyoxypropylene block copolymer as a reducing agent and protective agent and dissolve it in 50-80mL of deionized water, stir well to dissolve it completely, and prepare a copolymer solution;

[0036] According to the content of Pt-Pd alloy is 20~50wt%, the atomic ratio of Pd and Pt is 1:0.1~5 (the atomic ratio is preferably 1:1), take 0.5~4mL, 10~20mgPd / mL Na 2 PdCl 4 Aqueous solution and 0.5~4mL, 10~25mg Pt / mL K 2 PtCl 4 The aqueous solution was added to the above copolymer solution, stirred and reacted at 60~120°C for 2~5 hours, stirring continuously during the period, after the reaction was completed, cooled to room temperature (25°C±5°C), and brown-black Pt- Pd alloy nanoparticle sol;

[0037] Add 0.01 to 0.3 g of carbon black solution (Vulcan XC72 solution) to the above-mentioned Pt-Pd alloy...

Embodiment 1

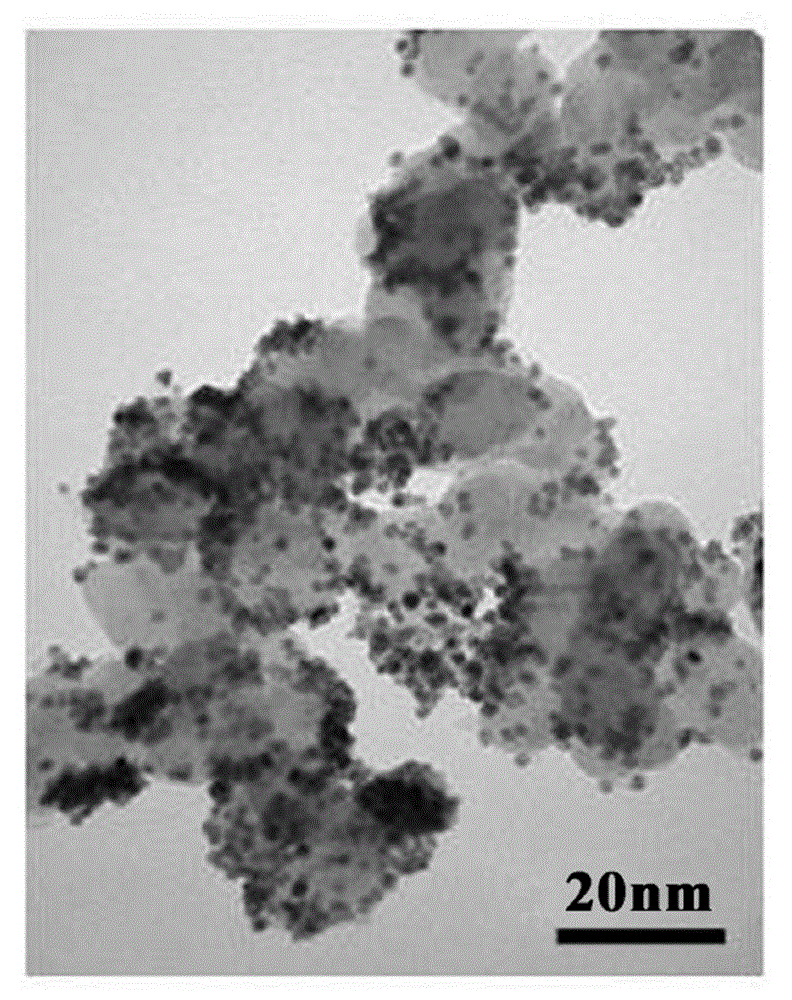

[0049] At 25° C., 7 g of a polyoxyethylene-polyoxypropylene block copolymer F88 (BASF Corporation) serving as a reducing agent and a protective agent was dissolved in 80 mL of deionized water to obtain a copolymer solution. 3.37mL, 10.85mg Pd / mL Na 2 PdCl 4 and 2.37mL, 14.1mg Pt / mL K 2 PtCl 4 The aqueous solution was added to the above-mentioned copolymer solution, and reacted at 75° C. for 2 hours. After the reaction was completed, it was cooled to room temperature (25° C.) to obtain a Pt-Pd alloy nanoparticle sol. 70mg of Vulcan XC72 dissolved in 14mL of ethanol carbon slurry solution was added to the above-mentioned Pt-Pd alloy nanoparticle sol, the resulting mixture was stirred, centrifuged, and dried to obtain 140mg of Pt-Pd alloy catalyst A, wherein the Pt content was 23.87wt %, the atomic ratio of Pd:Pt is 1:0.5. The particle size of the catalyst tested on a JEM-2000EX transmission electron microscope (JEOL, Japan) was 3.34nm.

Embodiment 2

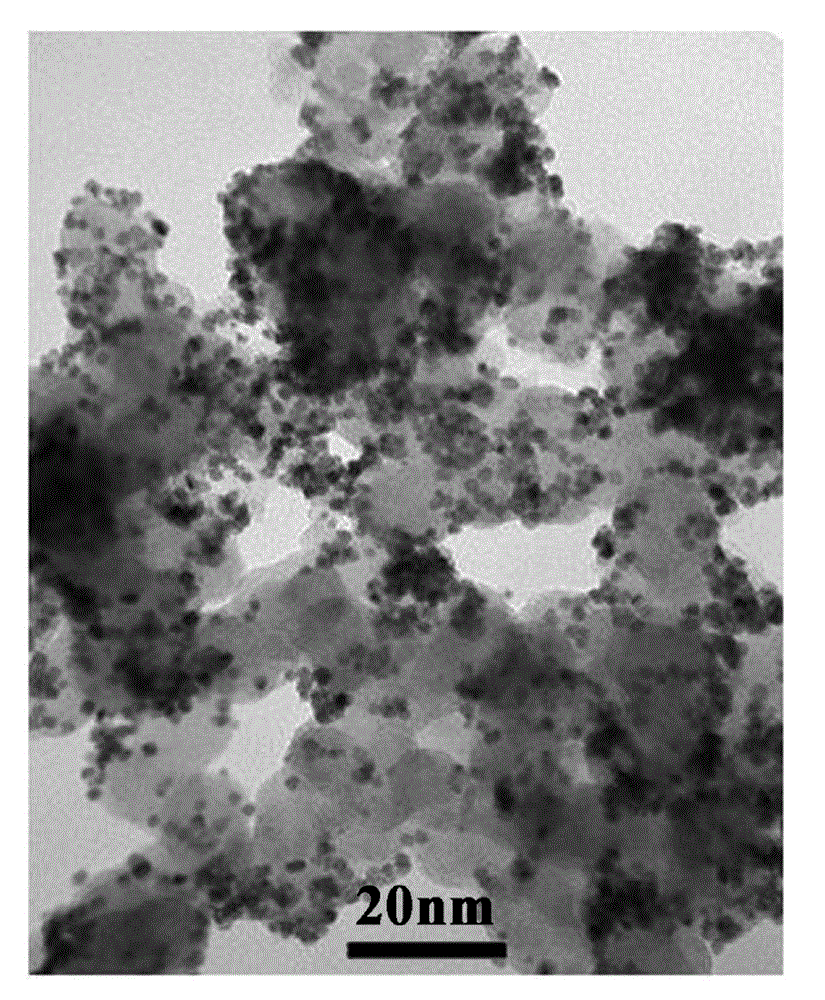

[0051] At 25° C., 10 g of polyoxyethylene-polyoxypropylene block copolymer F108 (BASF Corporation) serving as a reducing agent and a protective agent was dissolved in 71 mL of deionized water to obtain a copolymer solution. 1.41mL, 23mg Pt / mL of K 2 PtCl 4 and 0.97mL, 18.2mg Pd / mLNa 2 PdCl 4 The aqueous solution was added to the above copolymer solution, reduced at 85°C for 3 hours, and cooled to room temperature (25°C) to obtain a Pt-Pd alloy nanoparticle sol. 50mgVulcan XC72 of 10mL ethanol carbon slurry solution was added to the above-mentioned Pt-Pd alloy nanoparticle sol, the resulting mixture was stirred, centrifuged, and dried to obtain 100mg of Pt-Pd alloy catalyst B, wherein the Pt content was 32.4wt%, Pd : The atomic ratio of Pt is 1:1. The particle size of the catalyst tested on a JEM-2000EX transmission electron microscope (JEOL, Japan) was 3.45nm.

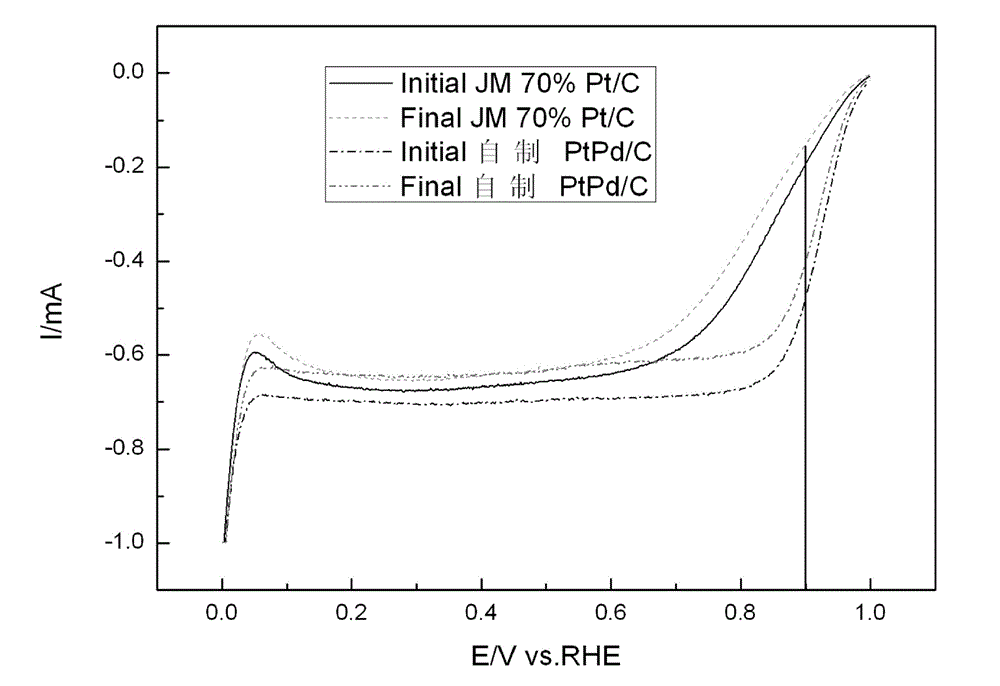

[0052] For the Pt-Pd alloy catalyst (self-made PtPd / C) and commercial catalyst (Johnson Matthey 70%Pt / C) obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com