Method and device for assistant brazing of airborne type brazing flux

A flux and brazing technology, which is used in auxiliary devices, tin feeding devices, welding equipment, etc., can solve the problems of poor wetting and spreading of liquid solder, pores in the weld, uneven coating, etc., to promote wetting. Spreading, increasing strength, evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

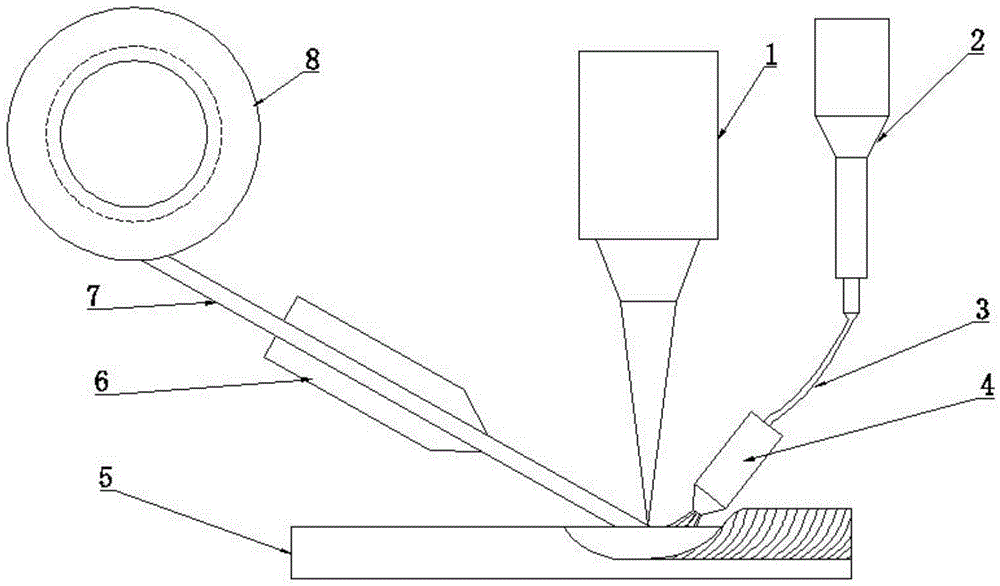

[0021] Embodiment 1: The method and device for airborne flux-assisted brazing of the present invention are firstly a powder feeder system, and the flux is loaded into the powder hopper 2 of the powder feeder, and then the air flow is adjusted so that the flux can Spray from the powder nozzle 4 smoothly without being too scattered; install the workpiece 5 so that the welding heat source 1 is just aligned with the position to be welded; adjust the direction of the welding wire 7 - the direction of the welding heat source 1 - the direction of the powder nozzle 4 to intersect at the same point, and weld During the process, first turn on the welding heat source and the airborne flux system, and then start the wire feeding after it is stable.

[0022] In the above-mentioned brazing (melting brazing) process, by adjusting the welding heat source line energy, welding speed, wire feeding speed, air flow, and powder wheel speed, a reasonable range of welding process parameters is obtaine...

specific Embodiment approach 2

[0023] Specific implementation mode two: using figure 1 The device shown is used for air-borne flux-assisted TIG surfacing experiments on steel surfaces. The welding wire is φ1.0mm Al-12Si welding wire, the steel plate is 316 stainless steel, the welding current is 90A, the welding speed is 0.3m / min, and the wire feeding speed is 3.0m / min, powder wheel speed 40 rpm, gas flow 3L / min.

specific Embodiment approach 3

[0024] Specific implementation mode three: using figure 1 The device shown is used for airborne flux-assisted fiber laser surfacing experiments on steel surfaces. The welding wire is φ1.2mm Al-5Mg welding wire, the steel plate is 316 stainless steel plate, and the welding parameters are: laser power 1800W, welding speed 0.5m / min, wire feeding speed 3.5m / min, powder wheel speed 40 rpm, gas flow 3L / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com