Preparation method of hybrid fiber reinforced polypropylene high-intensity composite material

A hybrid fiber and composite material technology is applied in the field of preparation of hybrid fiber reinforced polypropylene high-strength composite materials, which can solve the problems of not reaching fiber-reinforced polypropylene high-strength composite materials, the gap between varieties or quality, and the low strength grade. To achieve the effect of excellent interface bonding performance, good designability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

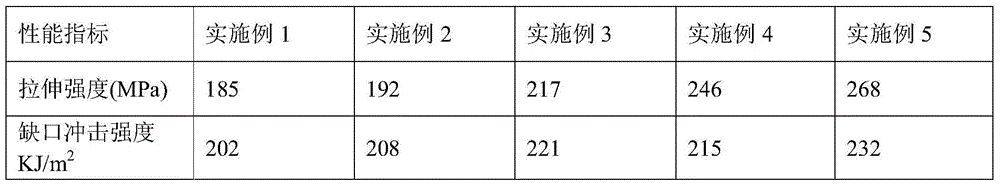

Examples

Embodiment 1

[0033] Step 1: Melt and blend PP-g-MAH, EVA, PP wax, and coupling agent at a mass ratio of 30:19:50:1 in an oven at a temperature of 190°C to prepare molten resin, and then glass Fiber and Kevlar fiber are mixed at a mass ratio of 80:20 to obtain a hybrid fiber, which is uniformly drawn through an impregnation tank containing molten resin at a certain speed (0.2r / s), and is continuously scraped to control the glue content (mass ratio less than 30%) to obtain modified plastic coated continuous hybrid fibers;

[0034] Step 2: Orientate the treated hybrid fibers on the surface of the flat metal mold by winding, the winding speed is 0.2r / s, and then hot press in a hot press at 180°C and 10MPa for 30min, and then cool After reaching room temperature, cut with a cutting machine to obtain a modified plastic-coated continuous hybrid fiber sheet;

[0035] Step 3: Mix and extrude PP pellets and EVA in a mixer with a mass ratio of 90:10 to obtain a polypropylene resin sheet, and laminat...

Embodiment 2

[0037] Step 1: Melt and blend PP-g-MAH, EVA, PP wax, and coupling agent at a mass ratio of 40:18:40:2 in an oven at a temperature of 190°C to prepare molten resin, and then glass Fiber and Kevlar fiber are mixed at a mass ratio of 70:30 to obtain a hybrid fiber, which is uniformly drawn through an impregnation tank containing molten resin at a certain speed (0.2r / s), and is continuously scraped to control the glue content (mass ratio less than 30%) to obtain modified plastic coated continuous hybrid fibers;

[0038] Step 2: Orientate the treated hybrid fibers on the surface of the flat metal mold by winding, the winding speed is 0.2r / s, and then hot press in a hot press at 180°C and 10MPa for 30min, and then cool After reaching room temperature, cut with a cutting machine to obtain a modified plastic-coated continuous hybrid fiber sheet;

[0039]Step 3: Mix and extrude PP pellets and EVA in a mixer with a mass ratio of 80:20 to obtain a polypropylene resin sheet, and laminate...

Embodiment 3

[0041] Step 1: Melt and blend PP-g-MAH, EVA, PP wax, and coupling agent at a mass ratio of 50:10:39:1 in an oven at a temperature of 190°C to prepare molten resin, and then glass Fiber and Kevlar fiber are mixed with a mass ratio of 60:40 to obtain a hybrid fiber, which is uniformly drawn through an impregnation tank containing molten resin at a certain speed (0.2r / s), and is continuously scraped to control the glue content (mass ratio less than 30%) to obtain modified plastic coated continuous hybrid fibers;

[0042] Step 2: Orientate the treated hybrid fibers on the surface of the flat metal mold by winding, the winding speed is 0.2r / s, and then hot press in a hot press at 180°C and 10MPa for 30min, and then cool After reaching room temperature, cut with a cutting machine to obtain a modified plastic-coated continuous hybrid fiber sheet;

[0043] Step 3: Mix and extrude PP pellets and EVA in a mixer at a mass ratio of 95:5 to obtain a polypropylene resin sheet, and laminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com