Method for preparing hemihydrate gypsum gel material and gypsum products on line by using phosphogypsum at hot stage

A technology of hemihydrate gypsum and cementitious materials, which is applied in the field of gypsum products, can solve the problems that the methods of cementitious materials and gypsum products have not yet appeared, and achieve the advantages of recycling, reducing the crystal transformation temperature, reducing land costs and transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for on-line preparation of hemihydrate gypsum cementitious material and gypsum products from phosphogypsum in hot state, specifically:

[0027] 1) Hot on-line pretreatment of phosphogypsum: using an aqueous solution of calcium hydroxide, the phosphogypsum discharged online is washed by a water washing process until the content of soluble phosphorus is 0.1wt.%, the content of soluble fluorine is 0.08wt.% and the content of organic matter 0.07wt.%, pH value between 5-7, dehydrated to obtain phosphogypsum slurry;

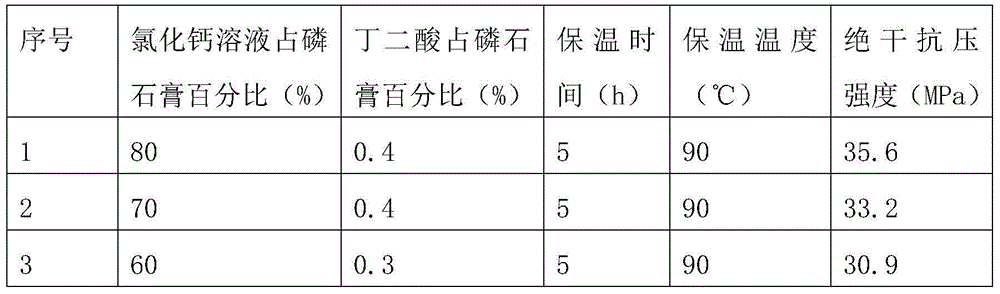

[0028] 2) On-line hydrothermal preparation process of phosphogypsum in hot state: fully mix the phosphogypsum slurry obtained in step 1) pretreatment with calcium chloride solution and succinic acid to form a slurry, wherein the mass of calcium chloride solution accounts for the mass of phosphogypsum 40%-90% of the calcium chloride solution, the concentration of the calcium chloride solution is 24wt.%, the amount of succinic acid is 0.01-2% of the mass ...

Embodiment 2

[0033]A method for on-line preparation of hemihydrate gypsum cementitious material and gypsum products from phosphogypsum in hot state, specifically:

[0034] 1) Hot on-line pretreatment of phosphogypsum: using an aqueous solution of calcium hydroxide, the phosphogypsum discharged online is washed by a water washing process until the content of soluble phosphorus is 0.1wt.%, the content of soluble fluorine is 0.08wt.% and the content of organic matter 0.07wt.%, pH value between 5-7, dehydration to prepare phosphogypsum slurry.

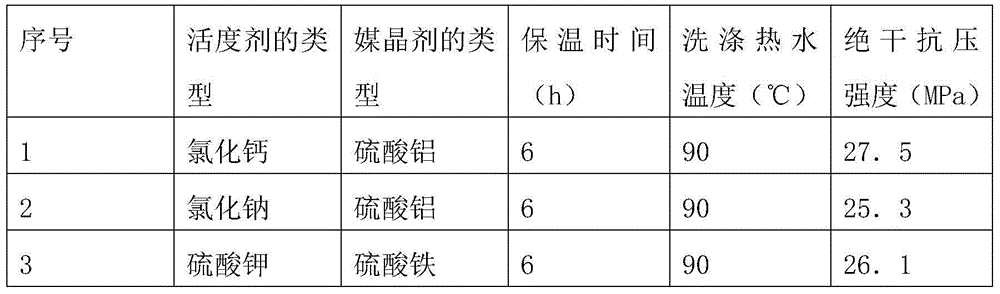

[0035] 2) On-line hydrothermal preparation process of phosphogypsum in hot state: fully mix the phosphogypsum slurry obtained in step 1) pretreatment with the active agent and the crystallization agent to form a slurry, wherein the mass of the active agent solution accounts for 10% of the mass of the phosphogypsum 50%, the concentration of the activity agent solution is 24wt.%, wherein the activity agent is calcium chloride, sodium chloride, potassium ...

Embodiment 3

[0040] A method for on-line preparation of hemihydrate gypsum cementitious material and gypsum products from phosphogypsum in hot state, specifically:

[0041] 1) Hot on-line pretreatment of phosphogypsum: using an aqueous solution of calcium hydroxide, the phosphogypsum discharged online is washed by a water washing process until the content of soluble phosphorus is 0.1wt.%, the content of soluble fluorine is 0.08wt.% and the content of organic matter 0.07wt.%, pH value between 5-7, dehydration to prepare phosphogypsum slurry.

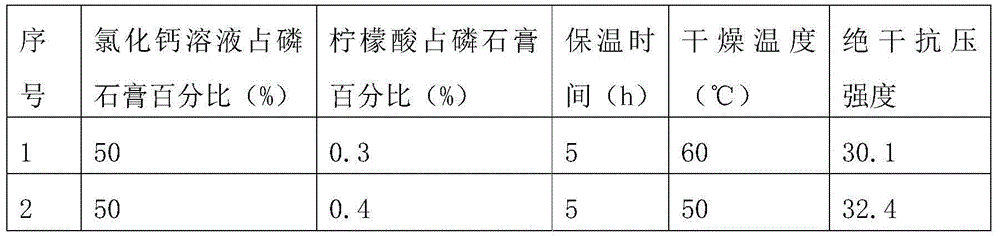

[0042] 2) On-line hydrothermal preparation process of phosphogypsum in hot state: fully mix the phosphogypsum slurry obtained in step 1) pretreatment with calcium chloride solution and citric acid to form a slurry, wherein the mass of calcium chloride solution accounts for 10% of the mass of phosphogypsum 50%, the concentration of the active agent solution is 24wt.%; the dosage of citric acid is 0.01-2% of the mass of phosphogypsum, and the slurry is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com