Preparation method of fish collagen

A technology of fish collagen and fish skin, applied in chemical instruments and methods, animal/human protein, connective tissue peptide, etc., can solve the problems of bitter smell, large volume of extraction liquid, high salt content, etc., and avoid a large amount of poisonous The use of harmful solvents, broad application prospects, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

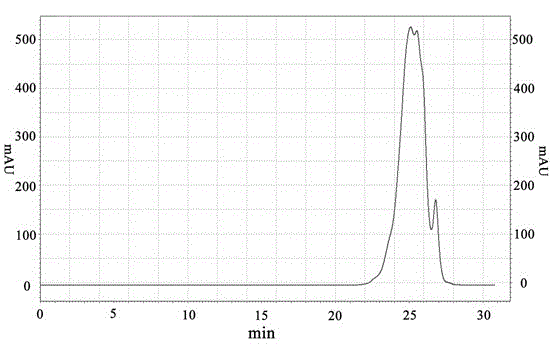

Image

Examples

Embodiment 1

[0021] Wash 1 kg of fish skin with water to remove some colored impurities. Add the pretreated fish skin into a high-speed shearing machine, add 10 times the weight of water and a mixed solution of ethanol (2:1, v : v ), heating with circulating water, controlling the temperature of the system at 45±1°C, performing shear extraction, so that the particle size of the fish skin reaches 10-15 microns, and obtaining a crude fish collagen extract. The crude fish collagen extract is filtered, and the residue is discarded to obtain a fish collagen extract. After the solvent is recovered, the fish collagen extract is concentrated to a relative density of 2.00, and the fish collagen product is obtained after spray drying. The product is a light yellow powder with good water solubility and no fishy smell. The purity of fish collagen is 56%.

Embodiment 2

[0023] Wash 5 kg of fish skin with water to remove some colored impurities. Add the pretreated fish skin to the homogenizer connected, add 25 times the weight of water, heat with steam, control the system temperature at 64±1°C, and carry out shear extraction to make the particle size of the fish skin reach 70- 90 microns to obtain the crude fish collagen extract. The crude fish collagen extract is filtered, and the residue is discarded to obtain a fish collagen extract. After the solvent is recovered, the fish collagen extract is concentrated to a relative density of 1.30, and the fish collagen product is obtained after freeze-drying. The product is white, with good water solubility and no fishy smell. The purity of fish collagen is 95%.

Embodiment 3

[0025] Wash 10 kg of fish skin with water to remove some colored impurities. Add the pretreated fish skin to the colloid mill, add 20 times the weight of water, ethanol and ethyl acetate mixed solvent (0.5:2:0.1, v : v : v ), use steam heating, control the system temperature at 30±1°C, use colloid mill to carry out circular shear extraction, make the particle size of fish skin reach 50-70 microns, and obtain fish collagen crude extract. The crude fish collagen extract is filtered, and the residue is discarded to obtain a fish collagen extract. After the solvent is recovered, the fish collagen extract is concentrated to a relative density of 1.50, and the fish collagen product is obtained after spray drying. The product is a light yellow powder with good water solubility and no fishy smell. The purity of fish collagen is 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com