Antistatic water-borne UV coating

An antistatic, water-based technology, applied in conductive coatings, polyester coatings, polyurea/polyurethane coatings, etc., to achieve good hardness, good solvent resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

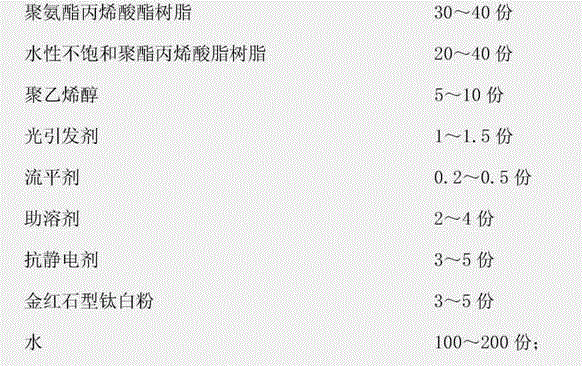

[0018] A kind of antistatic water-based UV coating is processed by the raw materials of following parts by weight:

[0019]

[0020] Wherein, the photoinitiator is 2-hydroxyl-2methyl-1-phenyl-acetone; the leveling agent is polyether polyester modified organosiloxane; the antistatic agent is ethyl Oxylated alkylamine; the purity specification of the co-solvent is analytically pure.

[0021] The preparation method of antistatic water-based UV paint of the present invention is:

[0022] 1. Weigh each component according to the above mass ratio;

[0023] 2. Mix polyvinyl alcohol, water-based unsaturated polyester acrylate resin and polyurethane acrylate resin to prepare a mixture;

[0024] 3. After adding photoinitiator, leveling agent and antistatic agent into the mixture, stir for 0.5h;

[0025] 4. Use the phase inversion method to slowly add water and co-solvent to disperse into a stable emulsion, and the dropping time is 1h.

example 2

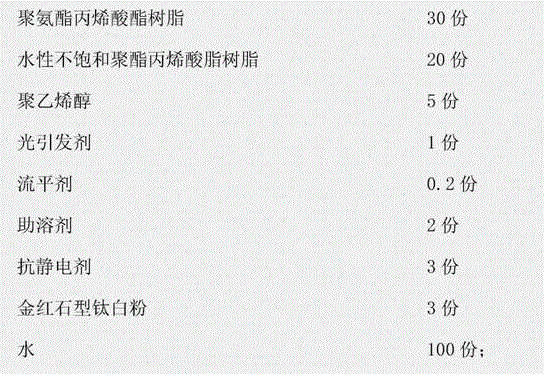

[0027] A kind of antistatic water-based UV coating is processed by the raw materials of following parts by weight:

[0028]

[0029] Wherein, the photoinitiator is 2-hydroxyl-2methyl-1-phenyl-acetone; the leveling agent is polyether polyester modified organosiloxane; the antistatic agent is ethyl Oxylated alkylamine; the purity specification of the co-solvent is analytically pure.

[0030] The preparation method of antistatic water-based UV paint of the present invention is:

[0031] 1. Weigh each component according to the above mass ratio;

[0032] 2. Mix polyvinyl alcohol, water-based unsaturated polyester acrylate resin and polyurethane acrylate resin to prepare a mixture;

[0033] 3. After adding photoinitiator, leveling agent and antistatic agent into the mixture, stir for 1.5h;

[0034] 4. Use the phase inversion method to slowly add water and co-solvent to disperse into a stable emulsion, and the dropping time is 2 hours.

example 3

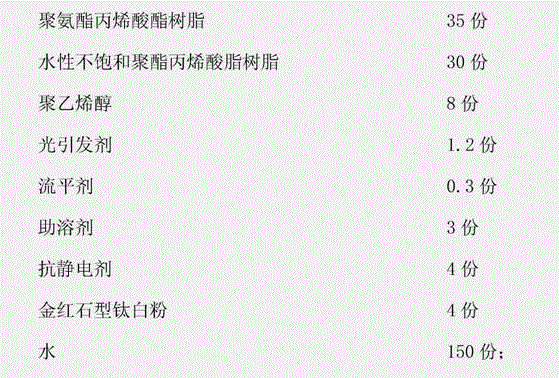

[0036] A kind of antistatic water-based UV coating is processed by the raw materials of following parts by weight:

[0037]

[0038] Wherein, the photoinitiator is 2-hydroxyl-2methyl-1-phenyl-acetone; the leveling agent is polyether polyester modified organosiloxane; the antistatic agent is ethyl Oxylated alkylamine; the purity specification of the co-solvent is analytically pure.

[0039] The preparation method of antistatic water-based UV paint of the present invention is:

[0040] 1. Weigh each component according to the above mass ratio;

[0041] 2. Mix polyvinyl alcohol, water-based unsaturated polyester acrylate resin and polyurethane acrylate resin to prepare a mixture;

[0042] 3. After adding photoinitiator, leveling agent and antistatic agent into the mixture, stir for 2 hours;

[0043] 4. Use the phase inversion method to slowly add water and co-solvent to disperse into a stable emulsion, and the dropping time is 3 hours.

[0044] Table 1 is the cured antista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com