Device for smokeless carbonizing treatment on crop straws

A technology of crop straw and smokeless charcoal, which is applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of air pollution, large energy consumption, etc., and achieve the effects of increasing grain output, low cost, and low operating energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

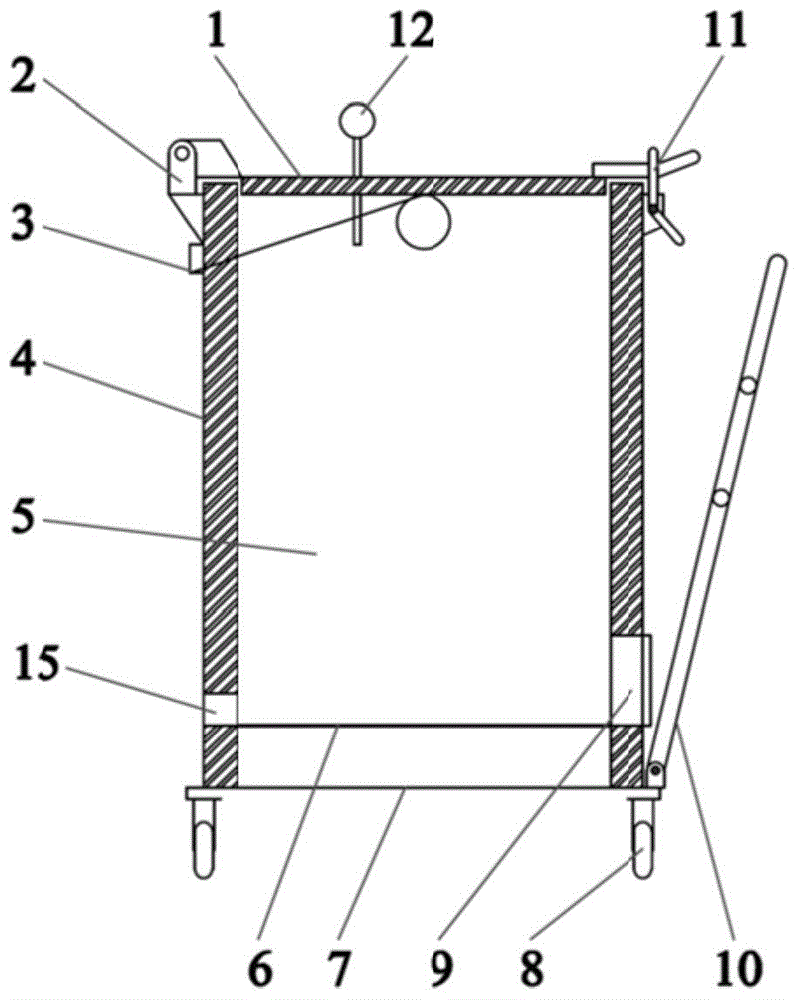

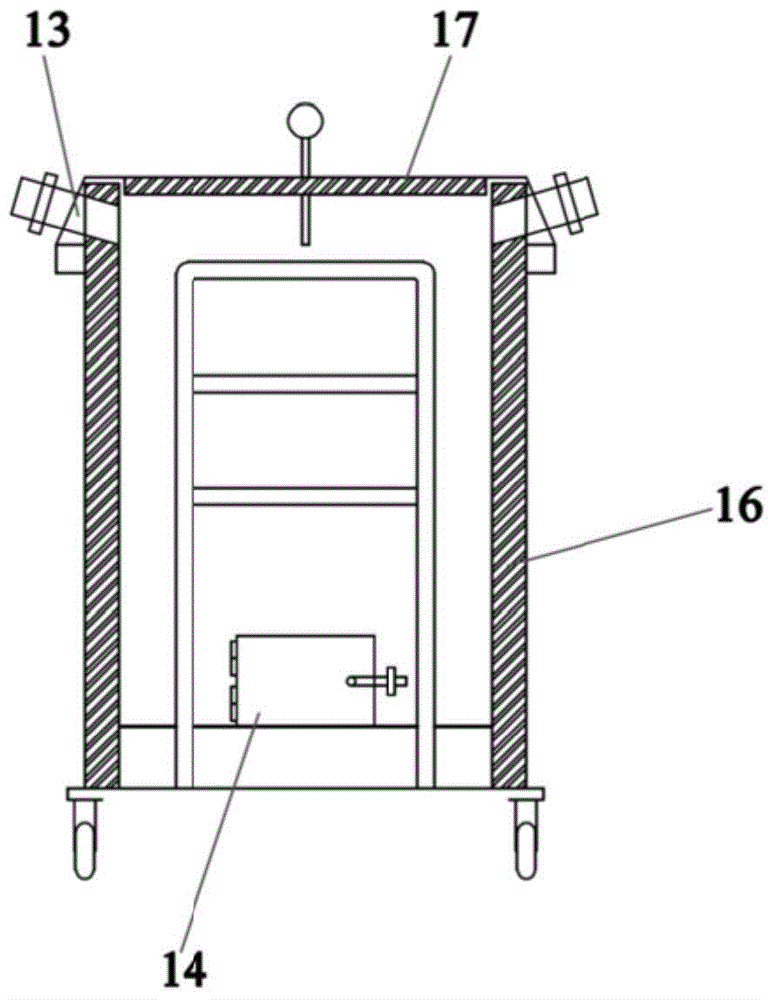

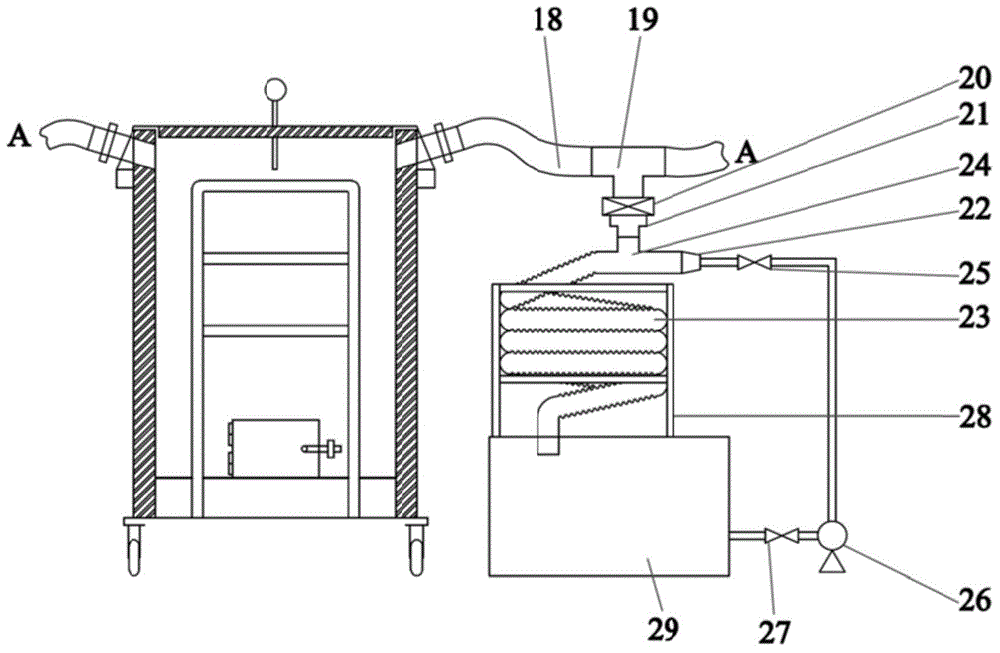

[0027] A device for smokeless carbonization of crop stalks, comprising two parts: a carbonization furnace and a purification device; the carbonization furnace includes a furnace cover 1 with an asbestos board 17 embedded with an insulating material, a furnace shell 4, and a carbonization chamber 5, Bottom plate 7, ash port 9, chimney 13, furnace door 14 and air inlet 15, and the lower part of carbonization chamber 5 is provided with furnace grate 6. The space between the shell 4 of the furnace body and the carbonization chamber 5 is filled with refractory bricks 16 of thermal insulation material. The air inlet 15 is located on the furnace body opposite the furnace door 14 and the ash port 9. The chimney 13 is arranged on both sides of the upper part of the carbonization furnace. The furnace cover 1 is rotatably connected with the furnace body shell 4 through a hinge 2, the furnace cover 1 is closed by a buckle 11 provided on the furnace body shell 4, the ash port 9 is located ...

Embodiment 2

[0034] Example 2 : Preparation of wheat straw charcoal

[0035] Adopt the device described in embodiment 1, open the furnace cover 1, load crop straws such as wheat straw, step on it while loading, and cover the furnace cover 1 tightly on the furnace body by buckle 11 after filling; The instrument 12 is inserted into the furnace body through the small hole in the center of the furnace cover; the furnace door 14 located at the lower part of the furnace body is opened, and the wheat straw is ignited; the furnace door 14 is closed, the axial flow AC fan and the magnetic drive circulation pump are turned on, and the wheat straw Slowly and evenly carbonize in the process, and the furnace is gradually cooled after the carbonization process is completed. After the stove is cooled to the ambient temperature, the furnace door 14 is opened, and the charcoal is discharged from the ash port 9 . When the stove is not in use, the stove can be moved to the warehouse by the handle 10 and t...

Embodiment 3

[0037] Example 3 : Preparation of Peanut Shell Charcoal

[0038] Adopt the device described in embodiment 1, open furnace cover, in furnace grate Lay a layer of straw or wheat straw on top, and then put the peanut shells from which the nuts have been peeled off into the carbonization chamber, fill it up, compact it, and cover the furnace cover tightly. Open the furnace door located at the lower part of the furnace body, ignite the straw or wheat straw, and then ignite the peanut shells; close the furnace door, turn on the axial flow AC fan and the magnetic drive circulation pump. After the carbonization furnace cools down to the ambient temperature, the carbonization process is completed. Open the furnace door and discharge the charcoal from the ash port. The ash content of environmental carbonization and ordinary carbonization products were 12.31% and 23.48%, respectively, and the quality of peanut shell biochar produced by environmental protection carbonization was also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com